Carbonization cleaning process of carbonizer for producing heavy soda ash

A heavy soda ash and carbonization tower technology, which is applied in the direction of carbonate preparations, can solve the problems of affecting production cycle and efficiency, high raw material consumption and energy consumption, and high water content of heavy alkali filter cake, so as to avoid carbonization shutdown and solve Pollution and waste of raw materials, the effect of increasing the degree of carbonization conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

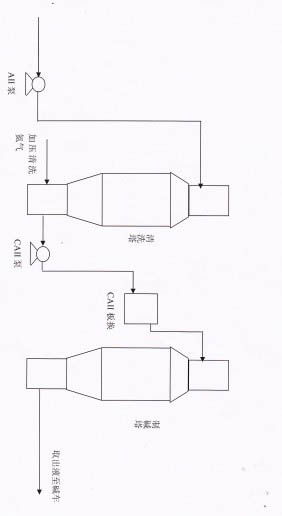

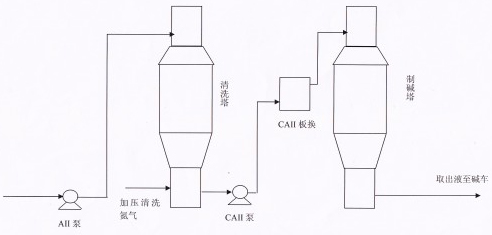

Image

Examples

Embodiment 1

[0027] A. Adopt marshalling operation, one tower is cleaned, and the remaining three towers are used for alkali production, and the towers are washed with ammonia mother liquor II in turn;

[0028] B, the ammonia mother liquor II that concentration is B1.02 is according to the flow rate of 450 cubic meters per hour, is continuously sent in the cleaning tower with pump pressurization, and feeds the mixed gas of low-concentration carbon dioxide gas and nitrogen, stirs; Wherein: The carbon dioxide gas concentration is controlled at 10%; the temperature of the mixed gas entering the tower is 35°C, and the flow rate is 1500 cubic meters per hour; the temperature of the ammonia mother liquor II is 40°C;

[0029] C. While dissolving the scars such as sodium bicarbonate and ammonium bicarbonate in the tower with ammonia mother liquor II, the ammonia in the ammonia mother liquor II reacts with carbon dioxide to obtain HCO 3- ;Achieve the purpose of absorbing carbon dioxide, and then pl...

Embodiment 2

[0034] A. Adopt marshalling operation, one tower is cleaned, and the remaining three towers are used for alkali production, and the towers are washed with ammonia mother liquor II in turn;

[0035] B, the ammonia mother liquor II that concentration is B1.06 is according to the flow rate of 500 cubic meters per hour, is continuously sent in the cleaning tower with pump pressurization, and feeds the mixed gas of low-concentration carbon dioxide gas and nitrogen, stirs; Wherein: The carbon dioxide gas concentration is controlled at 20%; the temperature of the mixed gas entering the tower is 37°C, and the flow rate is 2000 cubic meters per hour; the temperature of the ammonia mother liquor II is 35°C;

[0036] C. While dissolving the scars such as sodium bicarbonate and ammonium bicarbonate in the tower with ammonia mother liquor II, the ammonia in the ammonia mother liquor II reacts with carbon dioxide to obtain HCO 3- ;Achieve the purpose of absorbing carbon dioxide, and then pl...

Embodiment 3

[0041] A. Adopt marshalling operation, one tower is cleaned, and the remaining three towers are used for alkali production, and the towers are washed with ammonia mother liquor II in turn;

[0042] B, the ammonia mother liquor II that concentration is B1.04 is according to the flow rate of 550 cubic meters per hour, is continuously sent in the cleaning tower with pump pressurization, and feeds the mixed gas of low-concentration carbon dioxide gas and nitrogen, stirs; Wherein: The carbon dioxide gas concentration is controlled at 14%; the temperature of the mixed gas entering the tower is 40°C, and the flow rate is 1800 cubic meters per hour; the temperature of the ammonia mother liquor II is 38°C;

[0043] C. While dissolving the scars such as sodium bicarbonate and ammonium bicarbonate in the tower with ammonia mother liquor II, the ammonia in the ammonia mother liquor II reacts with carbon dioxide to obtain HCO 3- ;Achieve the purpose of absorbing carbon dioxide, and then pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com