Oil gas recycling special activated carbon and preparation method thereof

A technology of activated carbon and oil and gas, which is applied in the field of activated carbon and its preparation, can solve problems in the research and development stage, and achieve the effects of low price, operability and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the preparation of special activated carbon for oil and gas recovery

[0032] (1) Anthracite, potassium hydroxide and urea are mixed to obtain a mixture (wherein the mass fraction ratio of anthracite, potassium hydroxide and urea is 100:2:1), and then the mixture is crushed and pulverized to obtain More than 90% of the mixed powder is less than 180 meshes; the obtained mixed powder is subjected to columnar molding to obtain a columnar material;

[0033] (2) Carbonize the obtained columnar material to obtain a carbonized product, the final temperature of the carbonization is 600°C, and the heating rate is controlled to be 5°C / min;

[0034] (3) Activate the carbonization product obtained by steam to obtain the special activated carbon for oil and gas recovery, wherein the activation temperature is 900° C., and the activation time is controlled to be 3 hours.

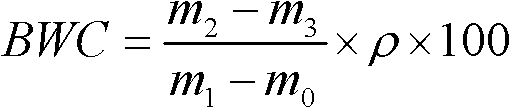

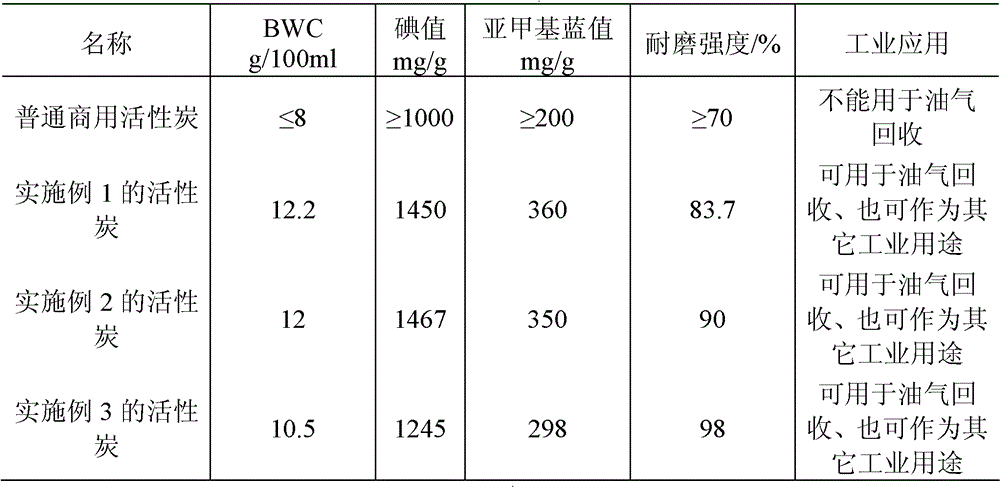

[0035] The performance index of the activated carbon prepared in this embodiment is shown in Table...

Embodiment 2

[0036] Embodiment 2, the preparation of special activated carbon for oil and gas recovery

[0037] (1) Mix bituminous coal, sodium hydroxide and ammonium sulfate to obtain a mixture (wherein the mass-number ratio of bituminous coal, sodium hydroxide and ammonium sulfate is 100:5:3), and then the mixture is crushed and pulverized Finally, more than 90% of the mixed powder less than 180 meshes are obtained; the obtained mixed powder is subjected to columnar molding to obtain a columnar material;

[0038] (2) Carbonize the obtained columnar material to obtain a carbonized product. The final temperature of the carbonization is 550° C., and the heating rate is controlled to be 5° C. / min;

[0039] (3) Activate the carbonized product obtained by steam to obtain the special activated carbon for oil and gas recovery, wherein the activation temperature is 800° C., and the activation time is controlled to be 4 hours.

[0040] The performance indexes of the activated carbon prepared in t...

Embodiment 3

[0041] Embodiment 3, the preparation of special activated carbon for oil and gas recovery

[0042] (1) Mix lignite, potassium nitrate and ammonium chloride to obtain a mixture (wherein the ratio of mass and number of lignite, potassium nitrate and ammonium chloride is 100:0.5:0.5), and then the mixture is crushed and pulverized Finally, more than 90% of the mixed powder less than 180 meshes are obtained; the obtained mixed powder is subjected to columnar molding to obtain a columnar material;

[0043] (2) Carbonize the obtained columnar material to obtain a carbonized product, the final temperature of the carbonization is 700°C, and the heating rate is controlled to be 10°C / min;

[0044] (3) Activate the carbonized product obtained by steam to obtain special activated carbon for oil and gas recovery, wherein the activation temperature is 900° C., and the activation time is controlled to be 1 h.

[0045] The performance indexes of the activated carbon prepared in this example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| methylene blue value | aaaaa | aaaaa |

| methylene blue value | aaaaa | aaaaa |

| methylene blue value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com