Bearing and conveying system

A load-carrying and carrying-surface technology, applied to conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as easy hand pinching, troublesome operation, and easy misalignment between movable trolleys and fixed platforms, etc., to achieve The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

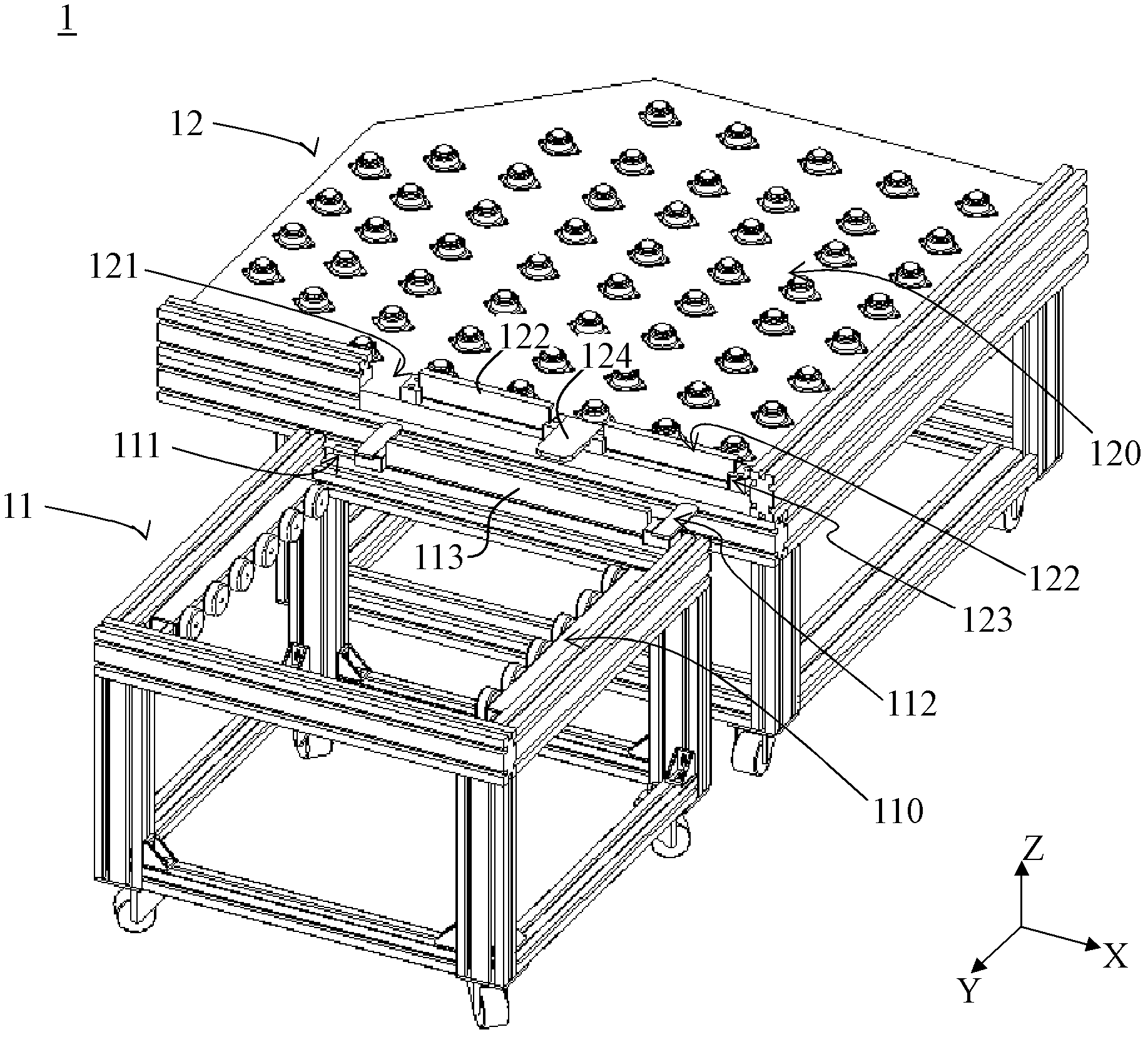

[0022] See figure 1 with figure 2 , figure 1 with figure 2 It is a schematic diagram of the carrying and conveying system 1 in an embodiment of the present invention in a separated state and a docked state, respectively. The carrier conveying system 1 includes a first platform 11 and a second platform 12 that can be docked with or separated from the first platform 11 . In practical applications, the first platform can be a movable trolley, and the second platform can be a fixed production line station, or vice versa; or both the first and second platforms are movable platforms, and the present invention does not This is not the limit.

[0023] The first platform 11 has a first bearing surface 110 and a first butt end 111 . The second platform 12 has a second b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com