Control method for oil injection device of track train, oil injection device, track train and track locomotive

A technology of fuel injection device and control method, which is applied in the directions of track lubrication, transportation and packaging, railway car body parts, etc., and can solve problems such as complex implementation, many management departments, and wrong judgments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

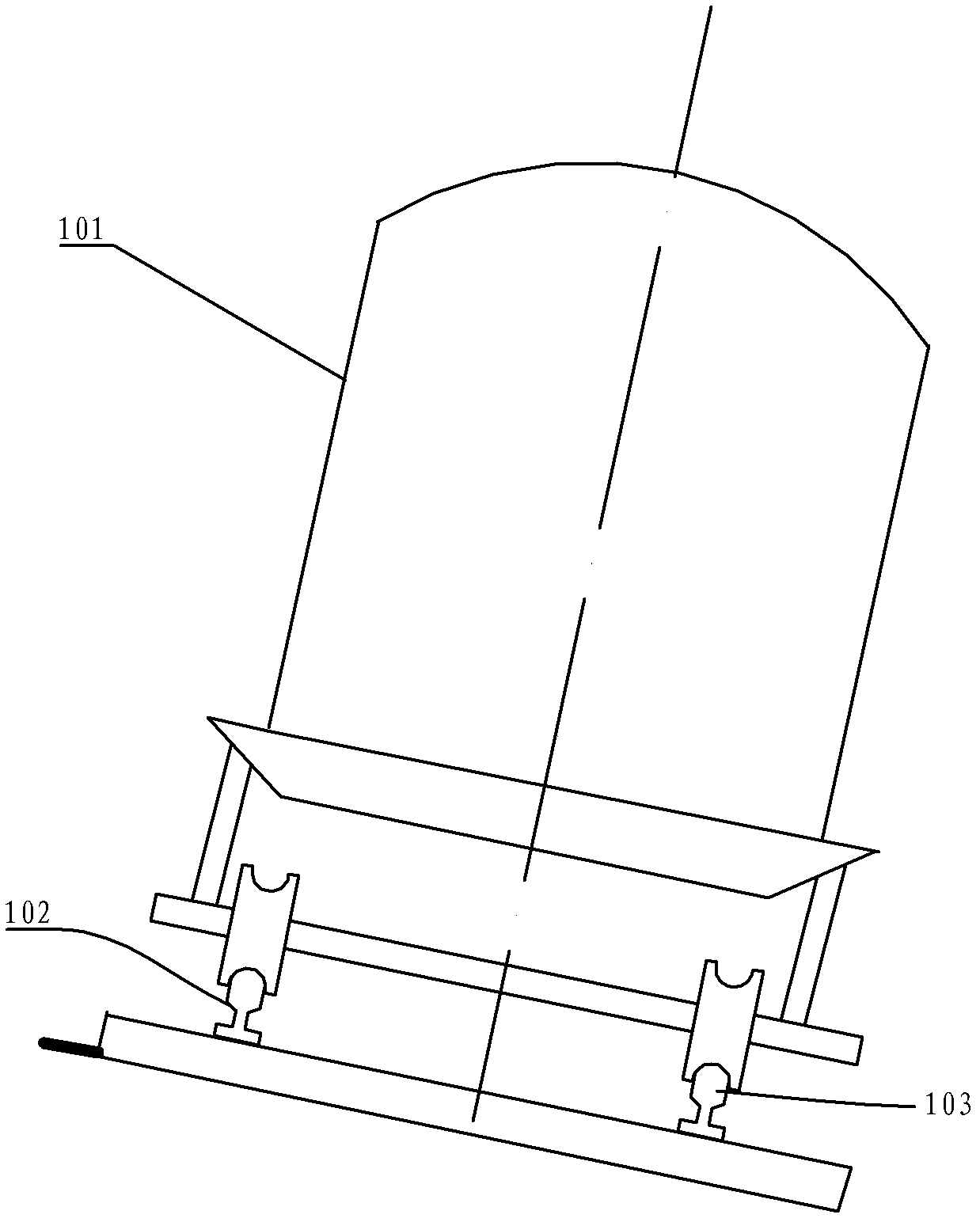

[0086] Such as Figure 5 As shown, the fuel injection device includes a fuel injector 30 , a control system 20 and a detection device 10 . The detection device 10 is electrically connected to the control system 20 and can transmit electrical signals to each other. The fuel injector 30 is electrically connected to the control system 20 .

[0087] The control system can adopt electronic computer or industrial computer.

[0088] Figure 6 It is a schematic diagram of the principle of the fuel injection device control method in the present invention. Such as Figure 6 As shown, the fuel injector includes an air compressor, an oil storage tank and a nozzle. The air compressor is respectively connected with the two oil storage tanks through the air duct, and the high-pressure gas produced by the air compressor can be filled into the oil storage tank. The oil storage tank is communicated with the nozzle through a grease pipe. The fuel injector is provided with an opening towar...

Embodiment 2

[0102] It differs from Embodiment 1 in that the structure of the fuel injector is different. Such as Figure 15 As shown, the fuel injector includes a fuel storage tank 302 , a fuel injection pipe 305 and a fuel pump 306 . The oil pump 306 is disposed in the oil storage tank 302 . The oil pump 306 communicates with the oil injection pipe 305 . When the oil pump 306 is in operation, the lubricating oil in the oil storage tank 302 can be sprayed to the wheel rim through the oil injection pipe 305 . The oil pump 306 is electrically connected to the control system 20 . The control system 20 can control the operation of the oil pump 306, and can control the power of the oil pump 306, so as to control the amount of fuel injection. All the other structures are the same as in Example 1.

Embodiment 3

[0104] Figure 16 It is a front view of the internal structure of the housing of Embodiment 3. Such as Figure 16 As shown, the difference between this embodiment and Embodiment 1 lies in the structure of the transmission amplification device. The transmission amplification device in this embodiment includes a third gear 41 , a fourth gear 51 and a transmission chain 45 . The third gear 41 , the fourth gear 51 and the transmission chain 45 are all installed in the inner cavity 1 of the housing 1 . Both the third gear 41 and the fourth gear 51 are circular gears. The third gear 41 is mounted on the first rotating shaft 2 . The third gear 41 can rotate with the first rotating shaft 2 . The fourth gear is rotatably mounted on the housing 1 through the second rotating shaft 6 . The contact piece 7 is installed on the fourth gear 51 . The third gear 41 and the fourth gear 51 are connected in transmission through a transmission chain 45 . All the other structures are the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com