Injection mold with retractable gate runner and electric pouring gate cutting device

A shearing device and injection mold technology, applied in the field of plastic injection molds, can solve problems such as high mold filling pressure and uneven filling, and achieve the effects of improving production efficiency, facilitating pressure maintenance and feeding, and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] For better understanding and implementation, specific embodiments are given below in conjunction with the accompanying drawings, and an injection mold with a retractable runner and an electric gate shearing device is described in detail.

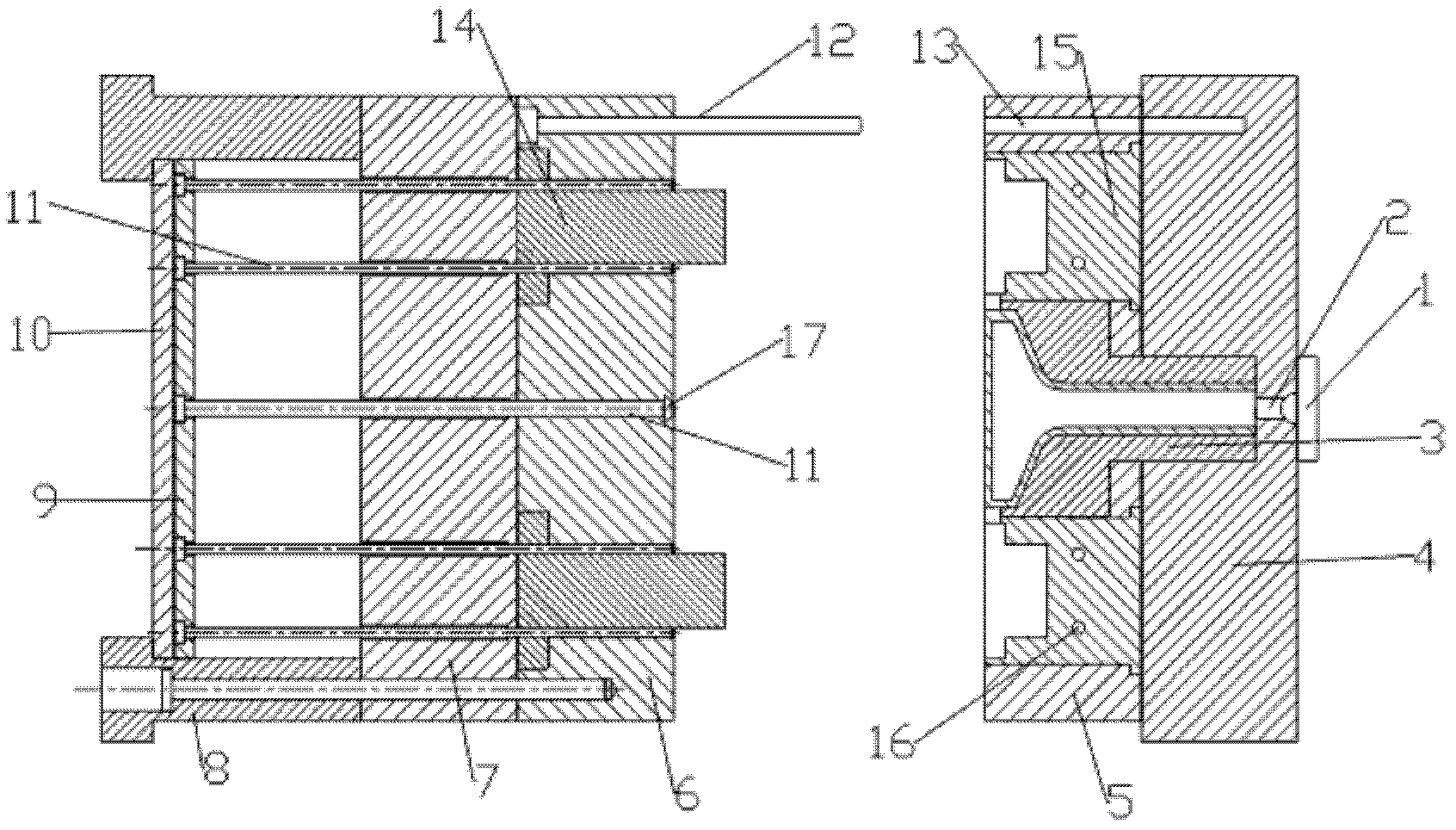

[0025] The present invention is an injection mold with a retractable runner and an electric gate shearing device, see figure 1 , including foot die 8, movable die pad 7, movable die plate 6, fixed die plate 5, fixed die bottom plate 4, punch 14, concave die 15, pouring system device 3, gate sleeve 2, positioning ring 1, large guide sleeve 13 , the large guide column 12, the ejector plate 9, the ejector bottom plate 10, the ejector rod 11, the cooling water channel 16; the fixed template 5 is fixed on the fixed mold bottom plate 4 by fasteners, and the pouring system device 3 is fixed on the fixed template 5, Inside and above the fixed mold base plate 4, two concave molds 15 are fixed in the fixed mold plate 5, a cooling water channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com