Flexible sheetmetal processing center

A processing center and sheet metal technology, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as single process function, large number of fixtures and molds, poor clamping and processing conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

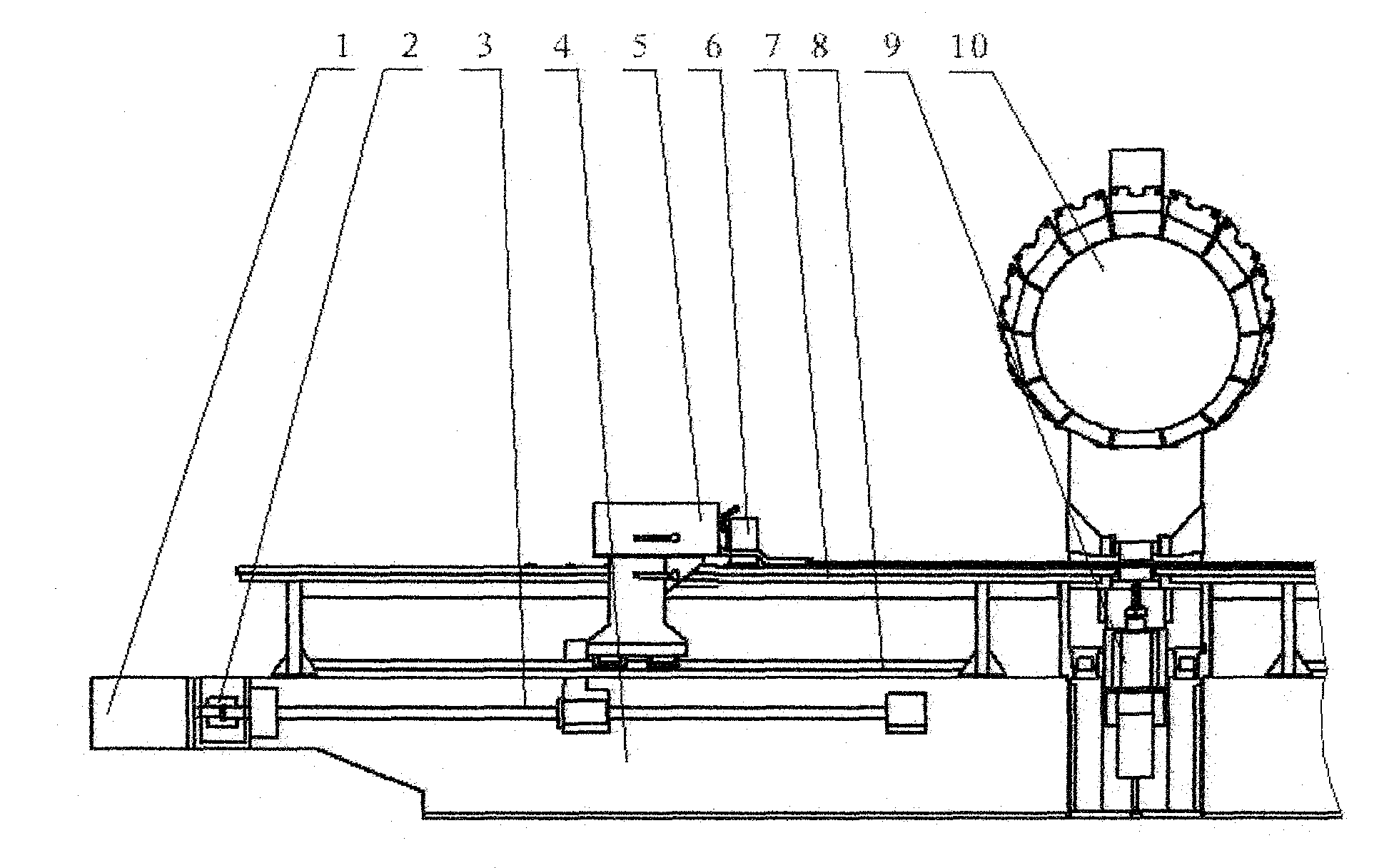

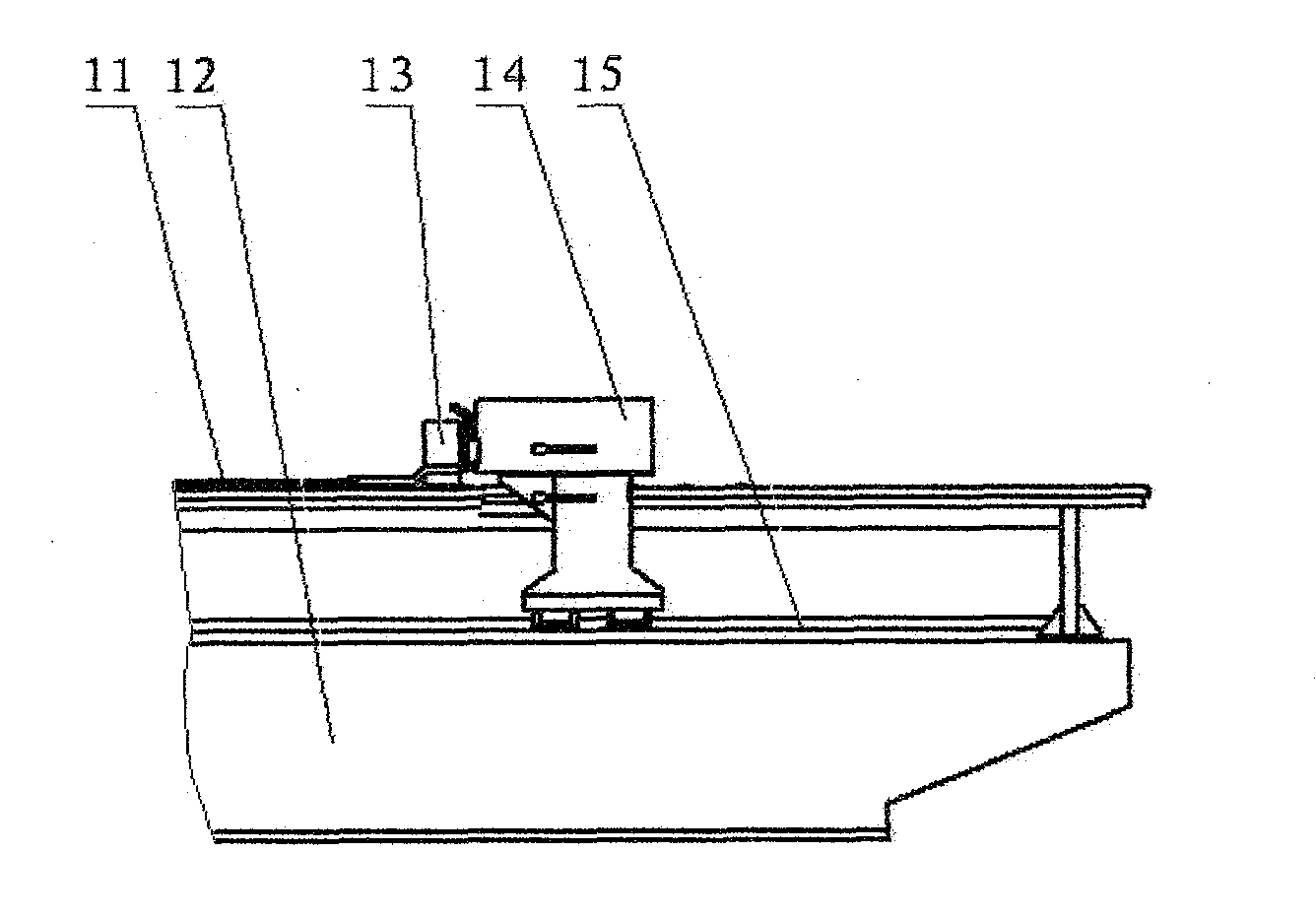

[0018]As can be seen from the figure, the X-direction screw part 3 is installed on the left base 4 by screws (it can also be installed on the right base 12), and the screw nut on the X-direction screw part 3 passes through the nut seat and the screw. Fixed to the bottom of the left beam 5, the X-direction servo motor 1 is connected with the X-direction screw part 3 through the coupling 2 to realize the X-direction drive; The mechanism that bar 41, front link 43 forms, one end of each pair of link mechanism is connected with left crossbeam 5 by screw and is fixed, and the other end passes through the sliding hole of right crossbeam 14 and is relatively slidably connected, and one side of the slide hole is provided with a handle type lock. Tighten the screw rod 45, when turning the handle to lock the screw rod 45, the rear connecting rod 41 and the front connecting rod 43 can be compressed, so that the left crossbeam 5 and the right crossbeam 14 are connected by the fastening con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com