Automatic punching and discharging machine for large-area zinc electrolyzing cathode plate

A technology of automatic punching and zinc electrolysis, applied in feeding devices, positioning devices, storage devices, etc., can solve the problems of high production cost and high cost, and achieve the effect of high production efficiency, long service life and good material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

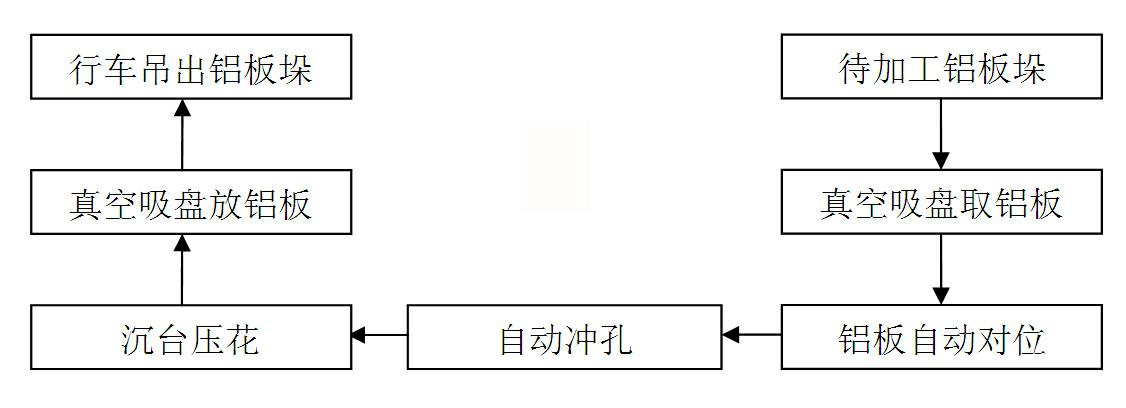

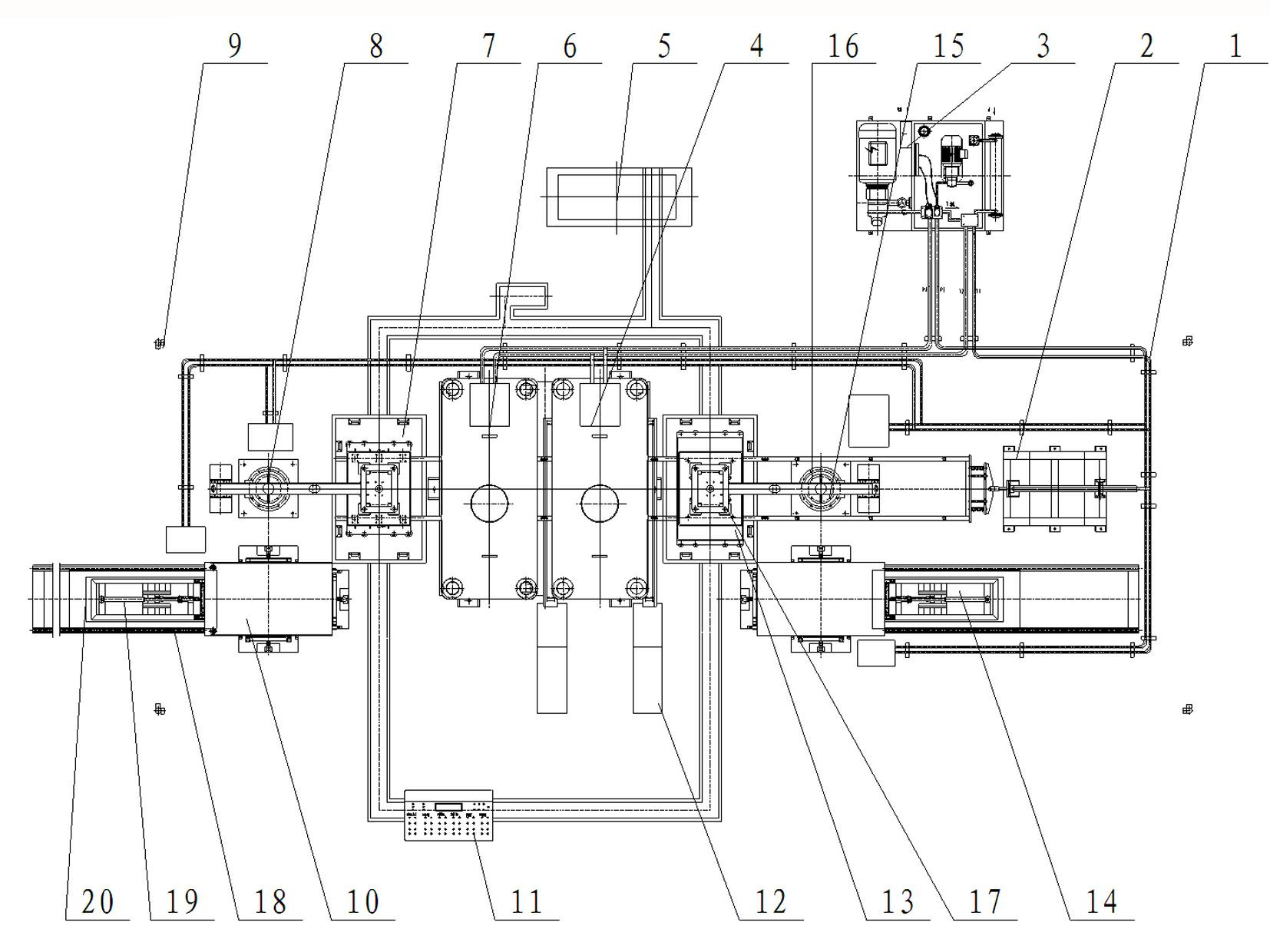

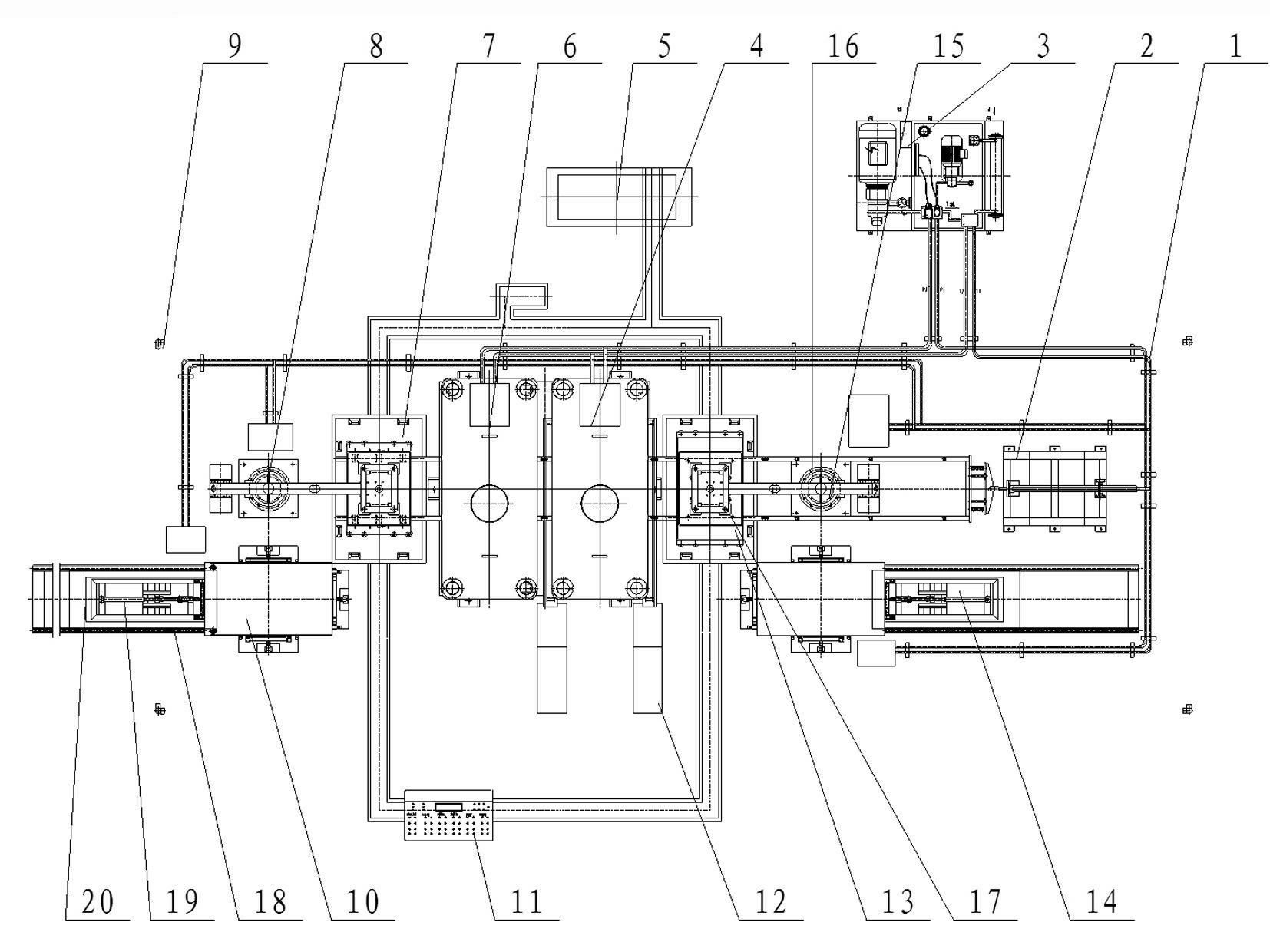

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0025] See figure 1 , figure 2 , a large-area zinc electrolysis cathode plate automatic punching and blanking machine, the present invention is characterized in that a feeding mechanism 14 arranged on the end surface of one side of the fuselage includes a guide rail 18, a cart 19 placed on the guide rail and a cart connected to the push rail. The stacking device 20 on the car; the feeding manipulator 13 arranged at the middle part of the fuselage includes a lifting device 15, a steering device 16 for rotating the lifting device and a vacuum sucker device 17 connected to the end of the lifting device; the punching machine 4 is arranged on the machine In the center of the body, the pushing device 2 is connected to the lifting device 15; the punching machine 4 and the pushing device 2 are respectively connected to the hydraulic station 3 through the hydraulic pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com