Method and apparatus used for promoting PM2.5 removing in tray column wet flue gas desulphurization

A wet flue gas desulfurization and tray tower technology, which is applied to combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of high steam consumption, low moisture content, and easy blockage of demisters, and achieves a high technological level. Simple, high-resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

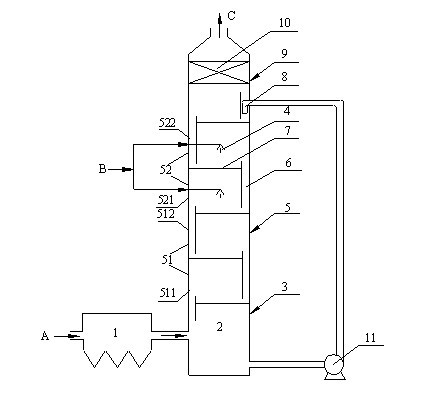

[0038] Promote PM in plate tower wet flue gas desulfurization of the present invention 2.5 The removal method is as figure 1 Shown: Coal-fired flue gas is removed by dust collector 1 to remove coarse dust with a particle size ≥ 2.5 microns, then enters the tower from the lower section 3 of the plate tower 2, and is sprayed out from the spray pipe 8 with the gas sent in by the circulating pump 11 The medium and low temperature desulfurization liquid is in countercurrent contact. After the coal-fired flue gas is in contact with the desulfurization liquid on several tray plates at the bottom tower section 51 of the middle tower section 5, the temperature of the flue gas drops from 100~150°C to 55~65°C, and the relative humidity increases to more than 70~80%. Then through the steam nozzle 4, an appropriate amount of normal-pressure saturated steam is injected into the middle tower section 5, that is, the upper tower section 52 of the desulfurization section, to make the flue gas...

Embodiment 2

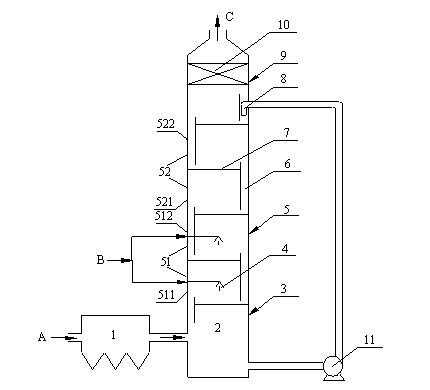

[0041] Such as figure 2 As shown, the difference from Example 1 is that after the flue gas contacts the desulfurization liquid on the bottom 1~2 trays of the desulfurization section 5, the temperature of the flue gas drops from 100~150°C to below 70°C, and the relative humidity increases to 50~60%, inject appropriate amount of normal-pressure saturated steam into the tower section 51 at the bottom of the desulfurization section 5 to make the flue gas saturated. saturation, occurs in PM 2.5 It is the vapor phase change process of condensation nuclei, and produces diffusion and thermophoresis, so that PM 2.5 Congeal and grow and then be captured by the desulfurization liquid on the subsequent multiple trays; wherein, the temperature of the medium and low temperature desulfurization liquid must be lower than the temperature of the saturated flue gas entering the tray by more than 20°C; the rest is the same as in Example 1.

Embodiment 3

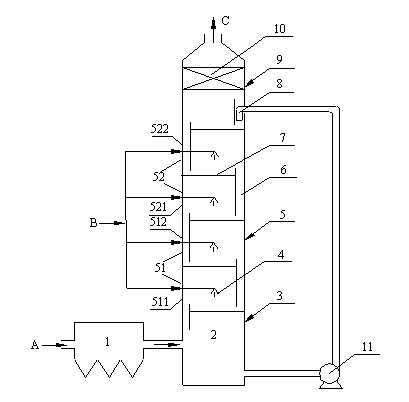

[0043] Such as image 3 As shown, the difference from Example 1 is that after the flue gas contacts the desulfurization liquid on the bottom 1~2 trays of the desulfurization section 5, the temperature of the flue gas drops from 100~150°C to below 70°C, and the relative humidity increases to 50~60%, at the bottom of the desulfurization section 5, the upper tower section injects an appropriate amount of saturated steam at normal pressure at the same time, so that the flue gas reaches saturation in the bottom tower section 51 and supersaturation in the upper tower section 52. The saturated flue gas in the bottom tower section 51 reaches supersaturation during the contact process with the medium and low temperature desulfurization liquid on the tray, making PM 2.5 The desulfurization liquid is condensed and grows up and is captured once by the desulfurization liquid on the tray where the bottom tower section 51 is located; the temperature of the medium and low temperature desulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com