Computer-aided design making method for dental personalized integrated non-metal post core

A core computer and aided design technology, applied in the field of personalized integrated non-metallic post and core computer aided design and production, can solve the problems of not meeting the accuracy requirements of clinical post and core repair, insufficient three-dimensional data accuracy, and inability to import into a numerical control center, etc. The effect of shortening the production cycle, reducing the risk of errors, and shortening the consultation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

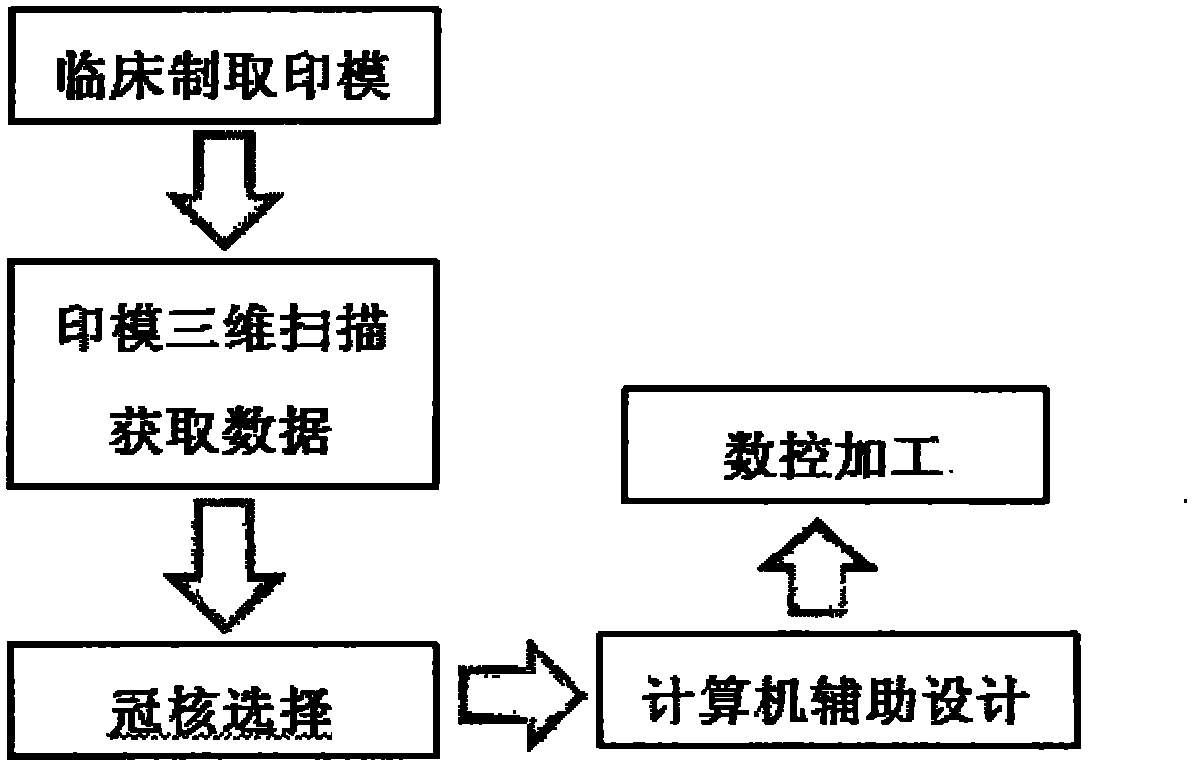

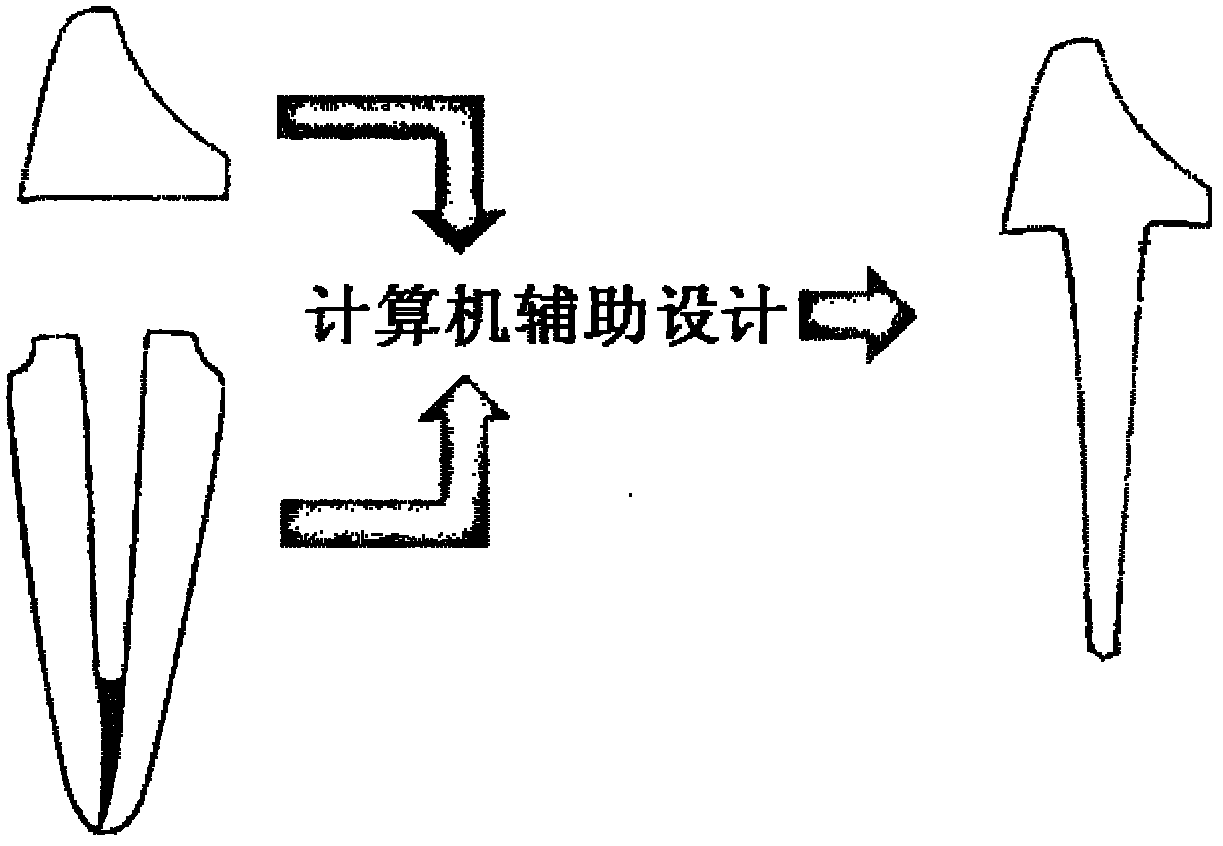

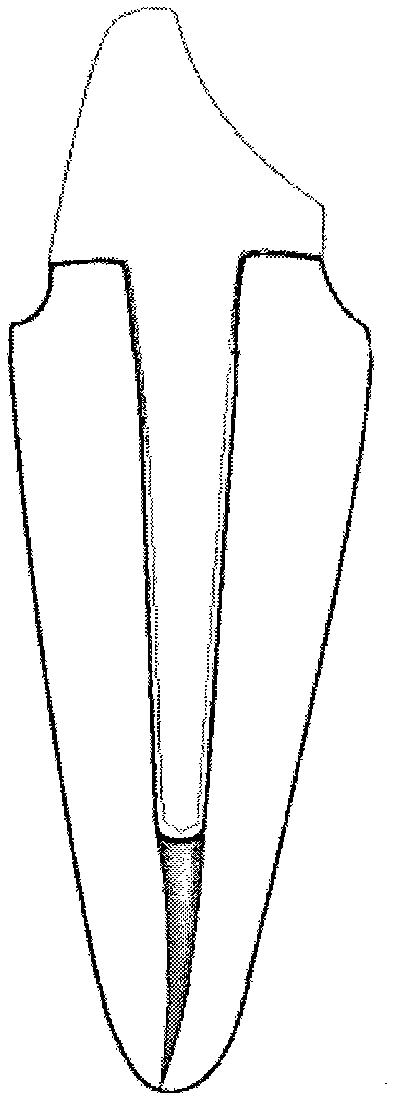

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail, as Figure 1 Shown, the technological process of the computer-aided design manufacturing method of this dental individualized integrated non-metallic post-core is:

[0026] Step (1): Clinical impression making 1; Routine restoration design and tooth preparation, making a full dentition silicone rubber impression including the cross-sectional shape of the affected tooth's root canal and tooth defect;

[0027] Step (2): Obtain data 2 by three-dimensional scanning of the impression; use a high-precision optical scanner (scanning accuracy better than 0.02mm) to scan the silicone rubber impression of the whole dentition prepared in step (1) to obtain the root canal and The three-dimensional data of the tooth defect section and the complete dentition, and the establishment of a virtual three-dimensional model;

[0028] Step (3): Crown nucleus selection 3; select the three-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com