Novel double-motor serial-parallel automatic switching device

An automatic switching, dual-motor technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of changing the motor output torque and speed, low cost, low efficiency, etc., to achieve high reliability and low cost Low, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following describes the present invention in further detail in conjunction with the description of the drawings and the specific embodiments:

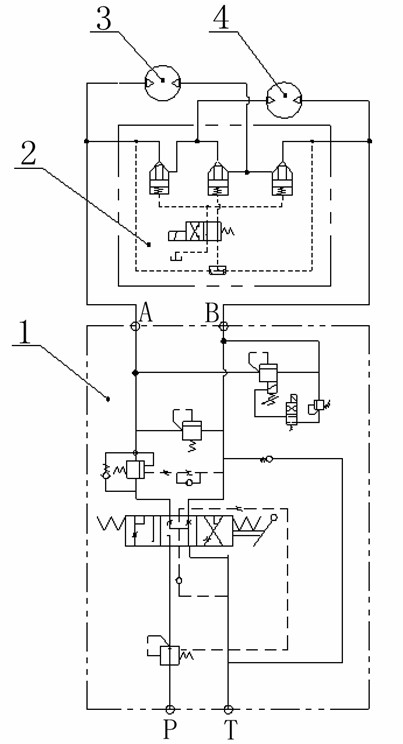

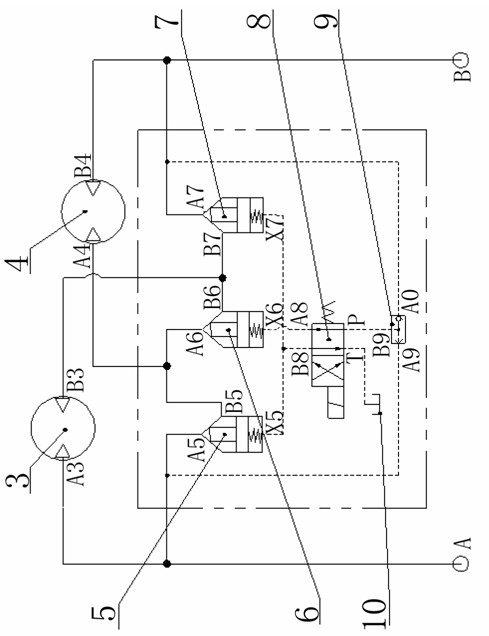

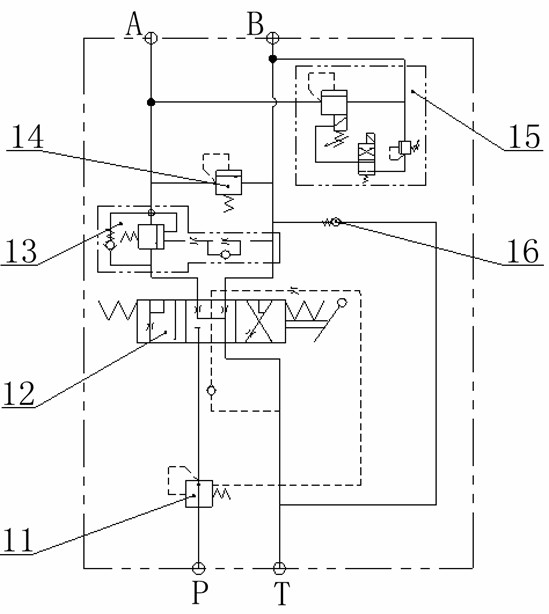

[0017] See figure 1 - image 3 , A new type of dual-motor series-parallel automatic switching device, including motor main control valve group 1, motor series-parallel switching valve group 2, Ⅰ motor 3 and Ⅱ motor 4, the motor series-parallel switching valve group 2 is inserted by I two-way It consists of valve 5, Ⅱ two-way cartridge valve 6, Ⅲ two-way cartridge valve 7, electromagnetic reversing valve 8 and shuttle valve 9. The working oil inlet A5 of the two-way cartridge valve Ⅰ is connected to the main motor The working oil inlet A of the control valve group 1 is connected to the working oil inlet A3 of the Ⅰ motor 3, and the working oil return port B5 of the Ⅰ two-way cartridge valve 5 is respectively connected to the working oil inlet A4 and Ⅱ of the Ⅱ motor 4 The working oil inlet port A6 of the two-way cartridge valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com