Cross section-variable underground continuous wall and construction method thereof

An underground diaphragm wall and construction method technology, applied in excavation, sheet pile wall, foundation structure engineering and other directions, can solve the problems of slow construction progress, difficulty in forming grooves, large height difference, etc., to save engineering costs, save manufacturing materials, Good water cutoff effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

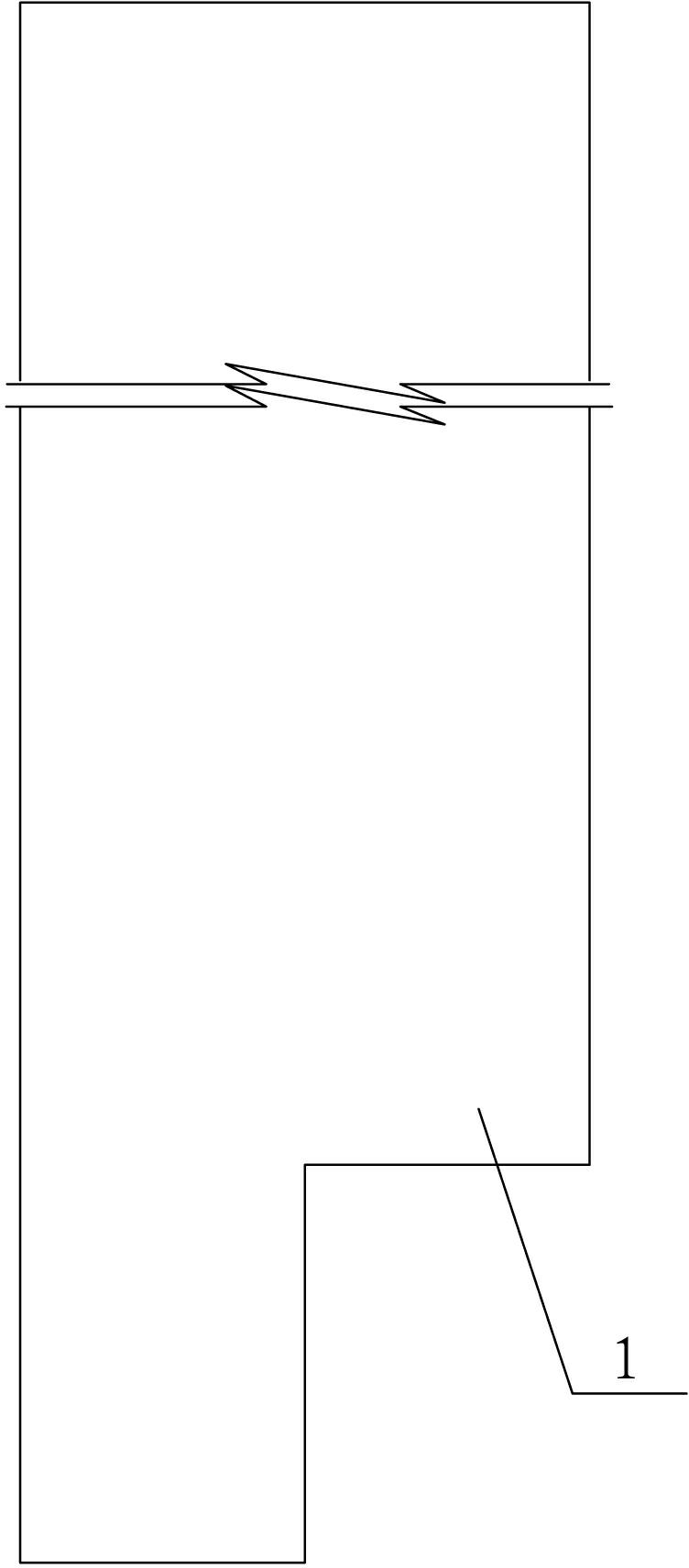

[0022] refer to figure 1 , the variable-section underground diaphragm wall is formed by connecting multiple underground diaphragm walls, and the bottom of a single underground diaphragm wall is in the shape of double steps along the width direction of the wall body 1 . That is to say, two steps are arranged at the bottom of the wall along the wall body 1 , and the extension direction of the step surface is in the same direction as the extension direction of the wall. The two steps at the bottom of the wall can be embedded in the rock layer under the sand layer, which has a good water interception effect; however, if a flat-bottomed underground diaphragm wall groove is excavated, a lot of rock needs to be broken, the construction volume is too large, and the labor intensity high.

[0023] refer to figure 2 , a construction method for a variable-section underground diaphragm wall, comprising the following steps:

[0024] a1) Measure the rock depth at the construction locatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com