Synthetic method of benzene dinitrile or substituted benzene dinitrile

A synthesis method, the technology of phthalonitrile, which is applied in the field of synthesis of phthalonitrile or substituted phthalonitrile, can solve the problems of large environmental impact and unsuitability for large-scale production, and achieve low environmental impact, low production pollution, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

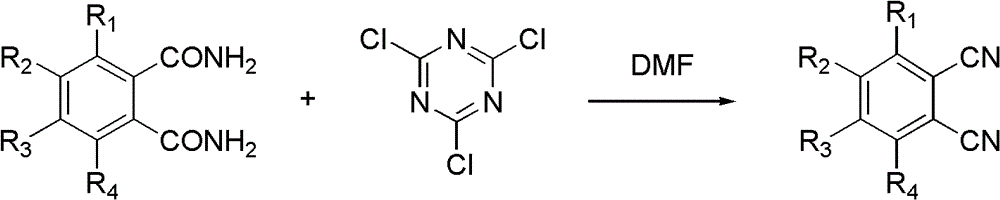

Method used

Image

Examples

Embodiment 1

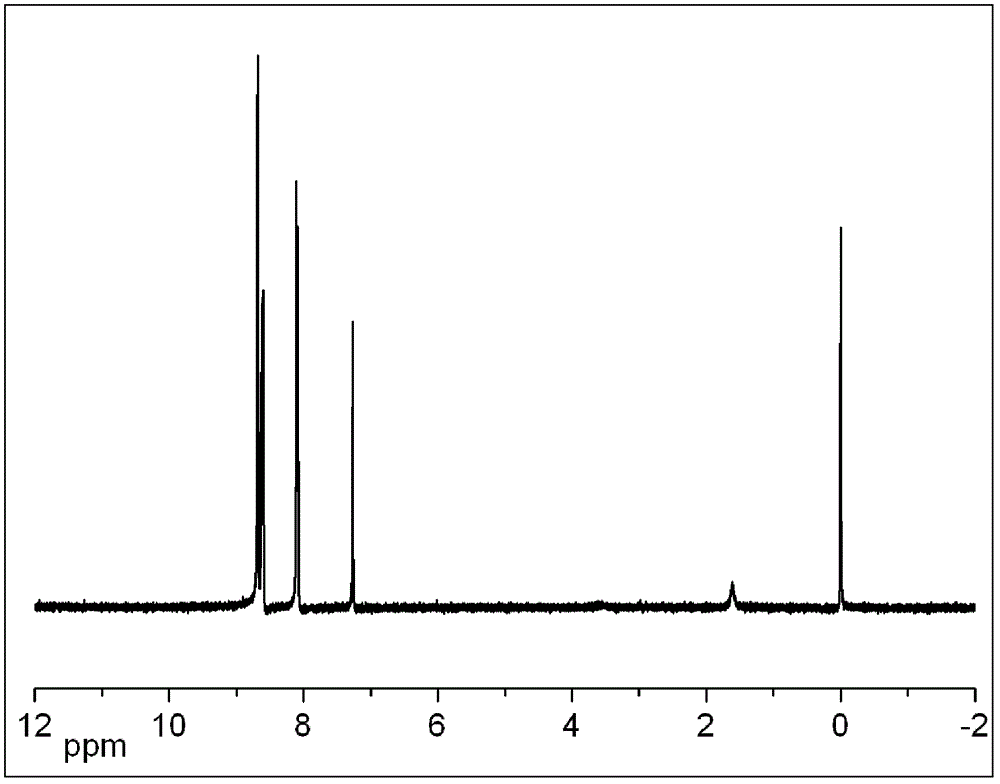

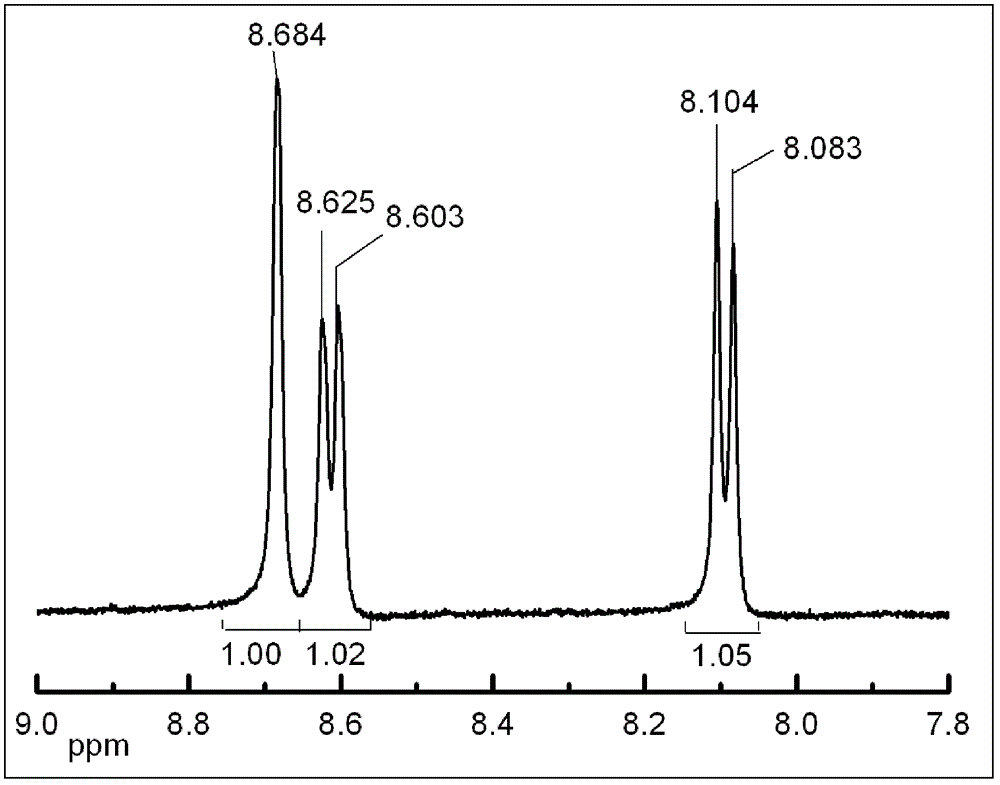

[0029] Add 37g 4-nitrophthalamide and 350mL DMF to a 500mL single-necked round-bottom flask, place it on a magnetic stirrer and stir for 30min, place the system in an ice bath, and wait until the temperature of the system drops below 5℃. 42.5g of cyanuric chloride, connected to the liquid sealing device, stirred for 20 minutes, removed the ice bath, and continued to stir for 48 hours at room temperature. Place the system in an ice bath, cool it down to 0°C, add 50mL of distilled water dropwise with a constant pressure funnel, control the dropping rate to keep the temperature of the system below 15°C, and pour it into 1.0L of ice water after the system is clear In the mixture. After filtration, it was washed with water and dried to obtain 29 g of 4-nitrophthalonitrile with a yield of about 95% and a melting point of 141-144°C. The hydrogen nuclear magnetic data of the target product is as follows figure 1 , figure 2 Shown: δ8.68(s, 1H), δ8.61(d, 1H), δ8.09(d, 1H).

Embodiment 2

[0031] Add 10g 4-nitrophthalamide and 100mL DMF to a 250mL single-necked round-bottom flask, place the system on a magnetic stirrer and stir, reduce the temperature of the system to 15℃, add 11.5g of cyanuric chloride, When the liquid sealing device is applied, the system exotherms violently, and a large amount of bubbles are generated. Continue to stir at this temperature for 5 hours and the reaction is complete. Then pour it into 500 mL of ice-water mixture. It is filtered, washed with water, and dried to obtain 8 g of 4-nitrophthalonitrile. The yield is about 97%. The product contains a small amount of impurities.

[0032] Note: When the input reactants are small, the temperature effect is not very obvious, but if the input reactants are more, the heat is excessively released, and more by-products will be produced.

Embodiment 3

[0034] Add 10g 4-nitrophthalamide and 100mL DMF to a 250mL single-necked round-bottom flask, place the system on a magnetic stirrer and stir, place the system in an ice bath, and wait until the temperature of the system drops below 5°C. Add 11.5g of cyanuric chloride, connect the liquid sealing device, stir for 20min, remove the ice bath, and then react at room temperature for 24h. Then put the system in an ice bath, wait until the temperature drops below 0℃, add 15mL distilled water dropwise to the system, keep the temperature below 15℃ during the titration process, pour it into 500mL ice-water mixture after the system is clear, and filter Then, it was washed with water and dried to obtain 6.5 g of 4-nitrophthalonitrile with a yield of about 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com