Improved metal sprinkler gun

A sprinkler head and metal technology, applied in the direction of spraying devices with movable outlets, spraying devices, etc., can solve the problems of easy breakage, easy loosening of adjustment and positioning, etc., to achieve the effect of reducing friction, overcoming working conditions, and improving uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

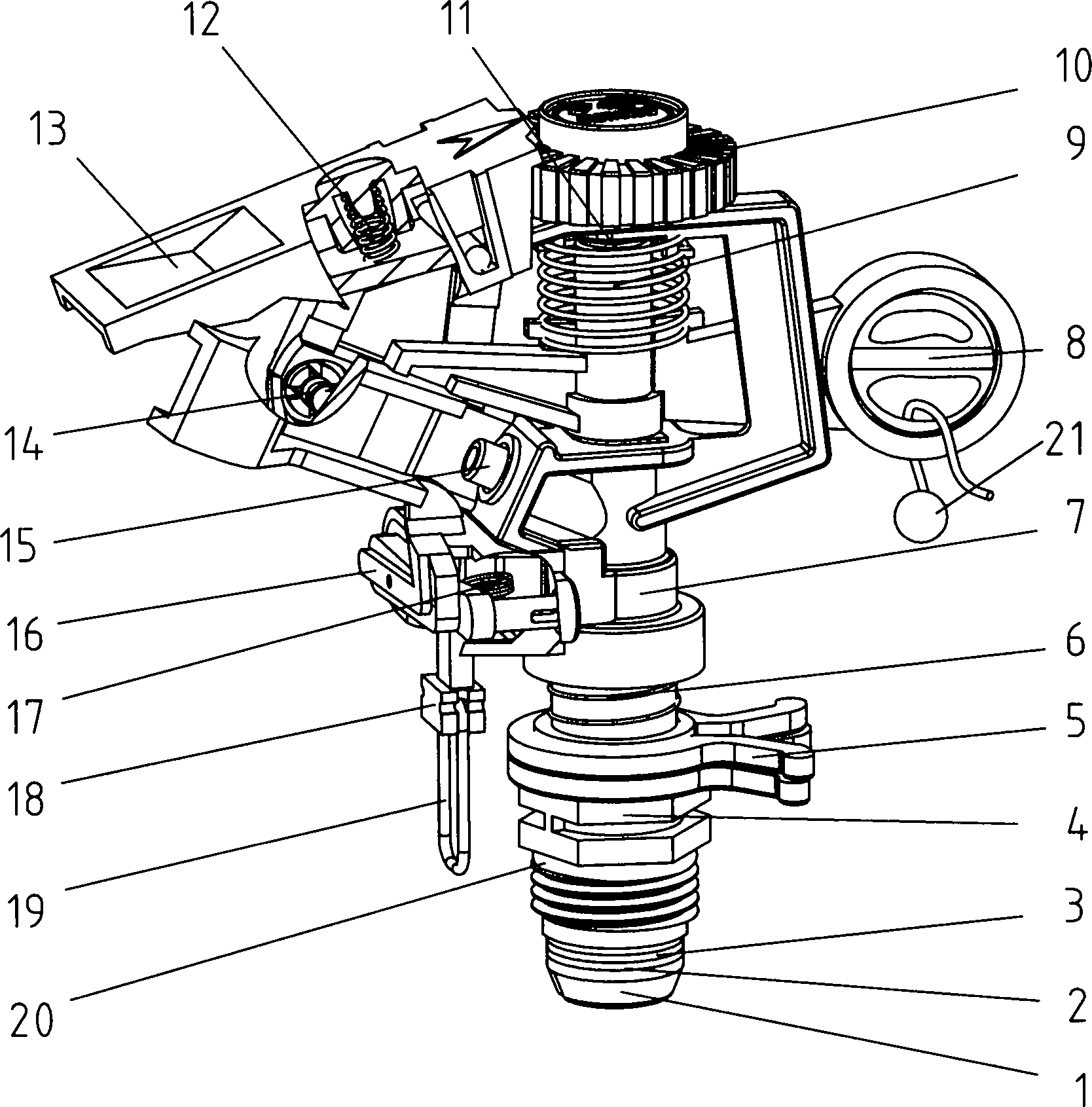

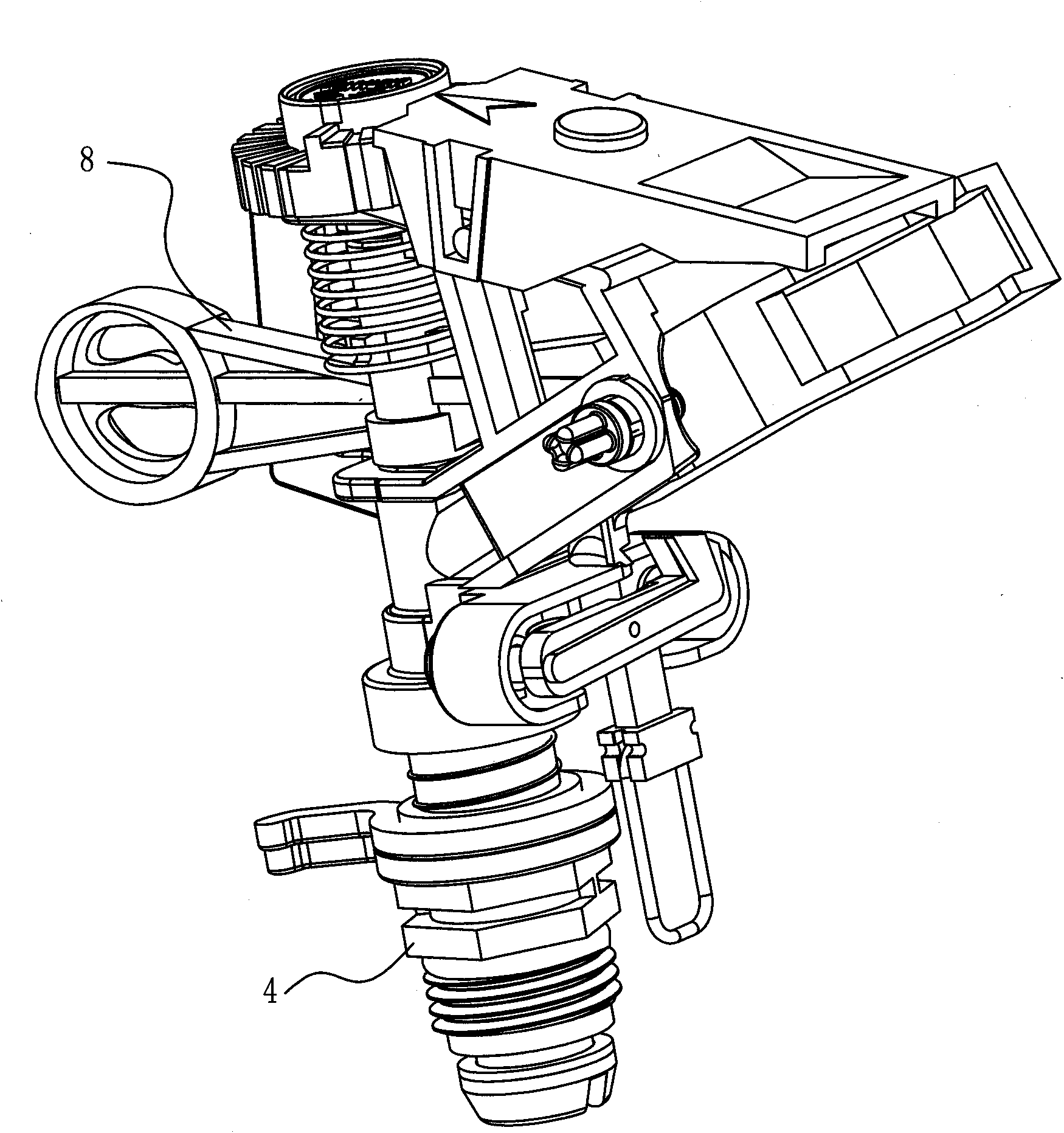

[0105] Below in conjunction with accompanying drawing and embodiment the above-mentioned invention is described further;

[0106] Because it is improved based on the plastic sprinkler head, and some parts are shared, but many parts are different in structure, so the plastic sprinkler head will be described first, and then the metal sprinkler head will be described.

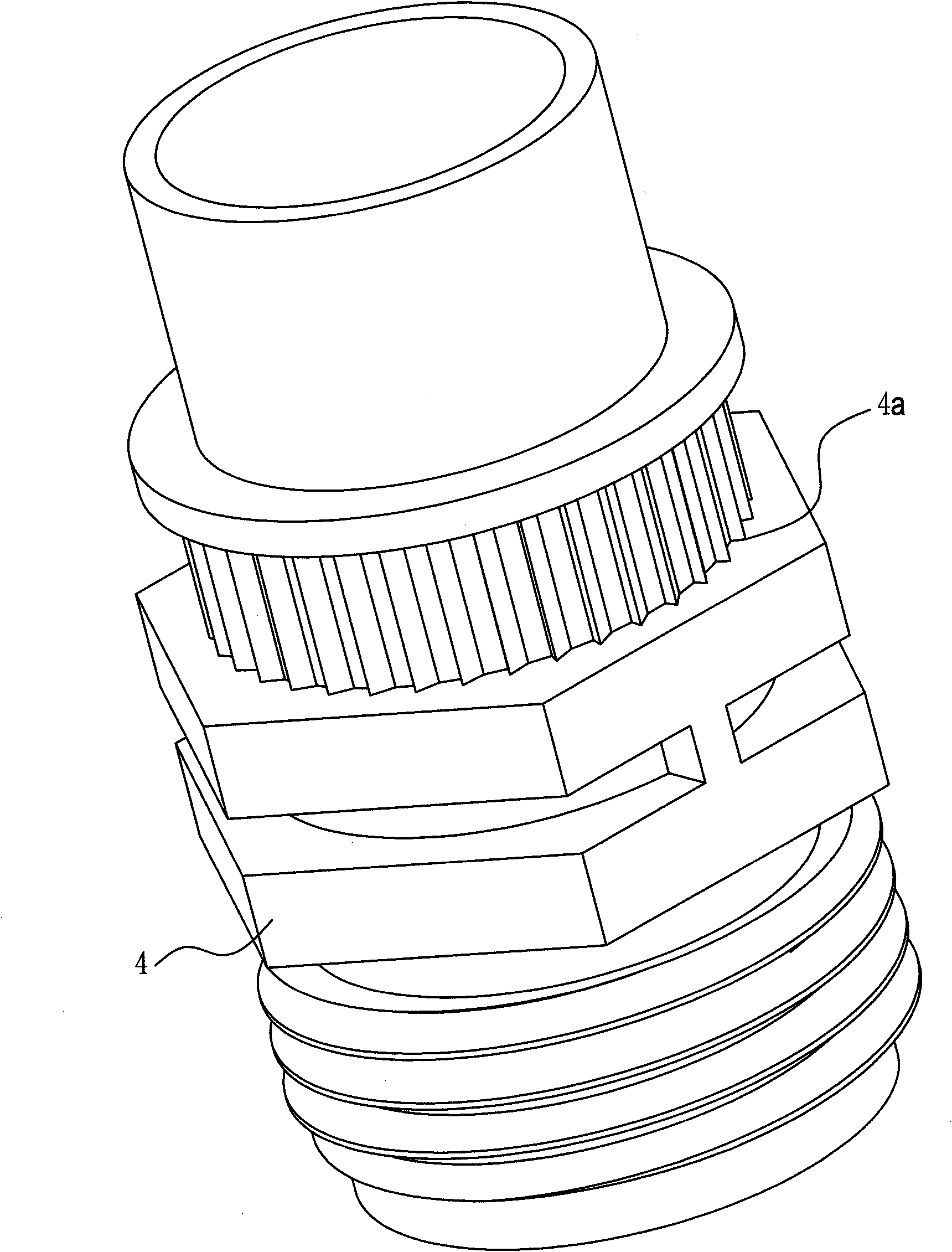

[0107] The invention relates to improving the key equipment of the sprinkler irrigation system, the plastic sprinkler head, which provides a method of improving the water target mixture, a method of reducing friction by using a functional wave clutch plate, a method of reversing the position by using a circumferential dense tooth, and using a parabola The method of the channel riser attempts to solve the problems of the existing plastic sprinkler heads, such as the easy breakage of the plastic water target, the easy loosening of the reversing positioning block over time, and the reduction of friction and sealing of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com