Spray bar, path and method for applying a medium onto a product

A product and medium technology, applied in the field of metal strip cooling, can solve problems such as the inability to optimally cool the rolled piece, the inability to continuously adjust the diaphragm, and the inability to always realize the water cooling width adjustability with sufficient fineness, achieving cost reduction Savings, improved accuracy, and media-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

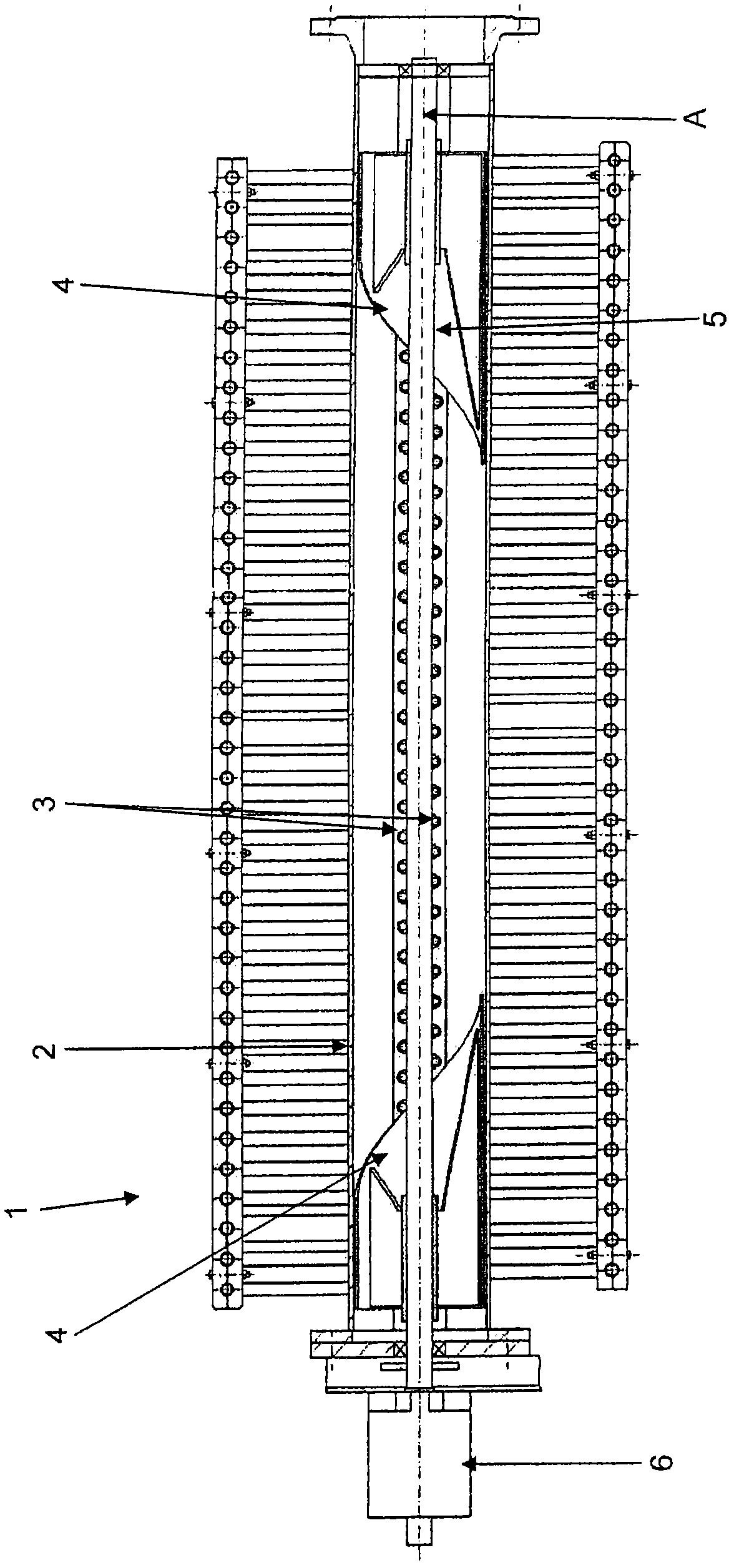

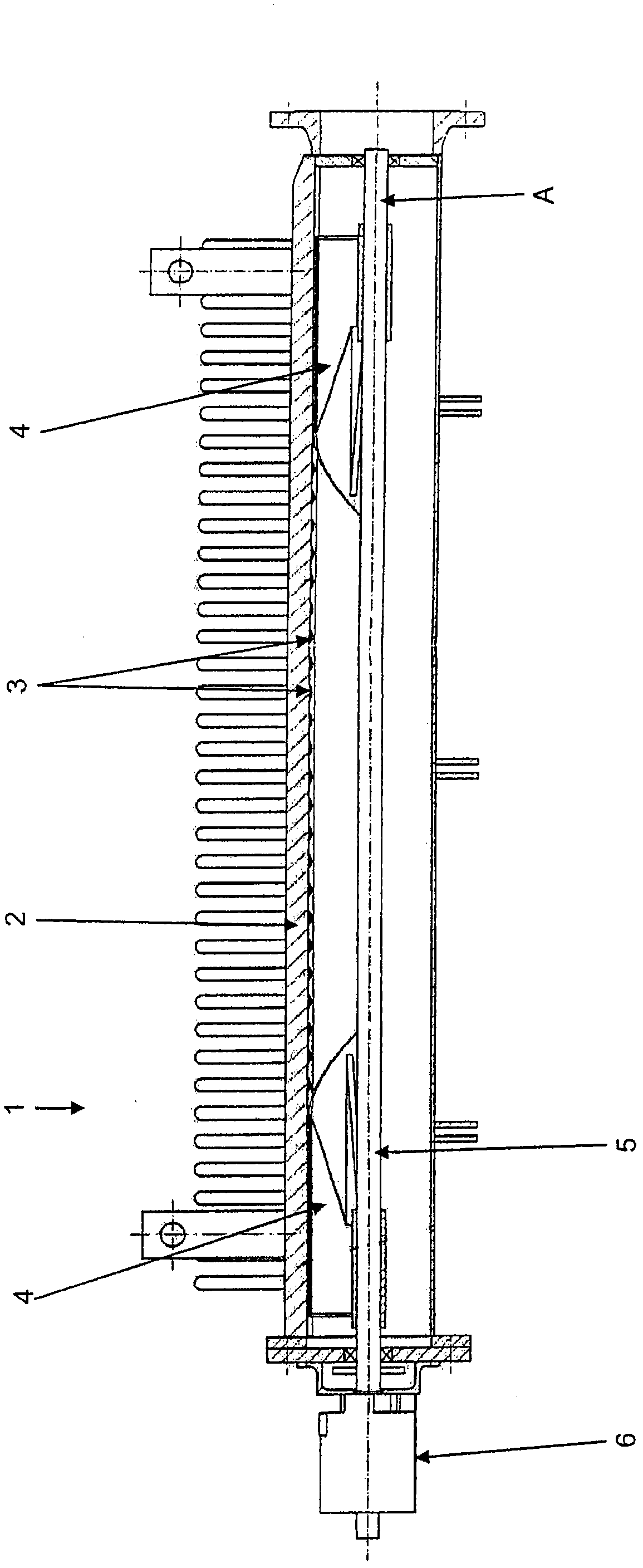

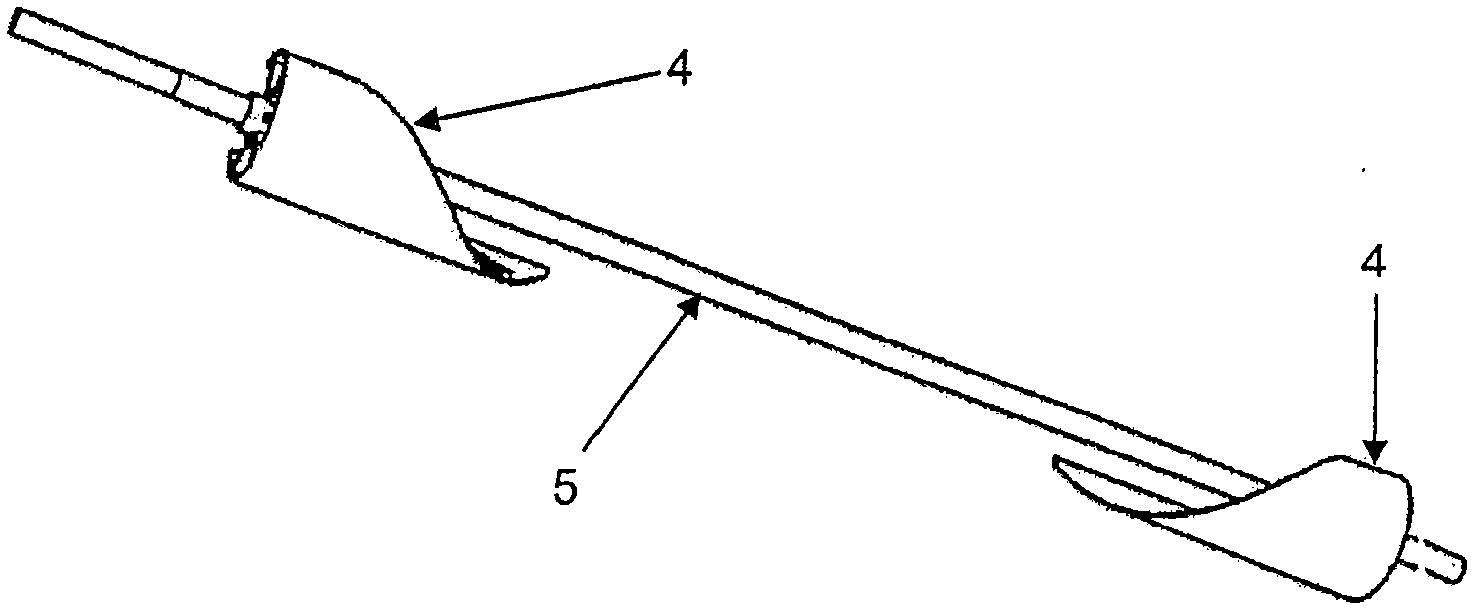

[0053] Figures 1 to 3 An embodiment of a spray beam 1 according to the invention is shown. here, figure 1 A horizontal cross-section through the spray beam 1 is shown. The spray beam 1 consists essentially of a cylindrical housing 2 which is hollow (hollow cylinder) and which can be supplied or filled with water. This feeding is preferably effected via one or more holes at the left or right end (in this case at the right end) of the hollow cylinder 2 . However, these holes can likewise be provided at other locations of the housing, for example in the side surfaces. At least one discharge opening 3 is provided in the housing 2 . In this exemplary case it is two rows each with equally spaced discharge holes 3, wherein these rows are shifted relative to each other so that the number of discharge holes 3 in the longitudinal direction A of the housing 2 is compared to only one Row 3 doubles. Other arrangements of the outlet openings 3 are also possible, depending on the resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com