Self-recovery stop type protection circuit for low-voltage and high-power safety barrier

A technology for protecting circuits and power switching circuits, applied in the direction of protection against overcurrent, etc., can solve the problems of safety hazards, monitoring and monitoring systems that are not widely used, and achieve low power loss, novel and reasonable design, and low power loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

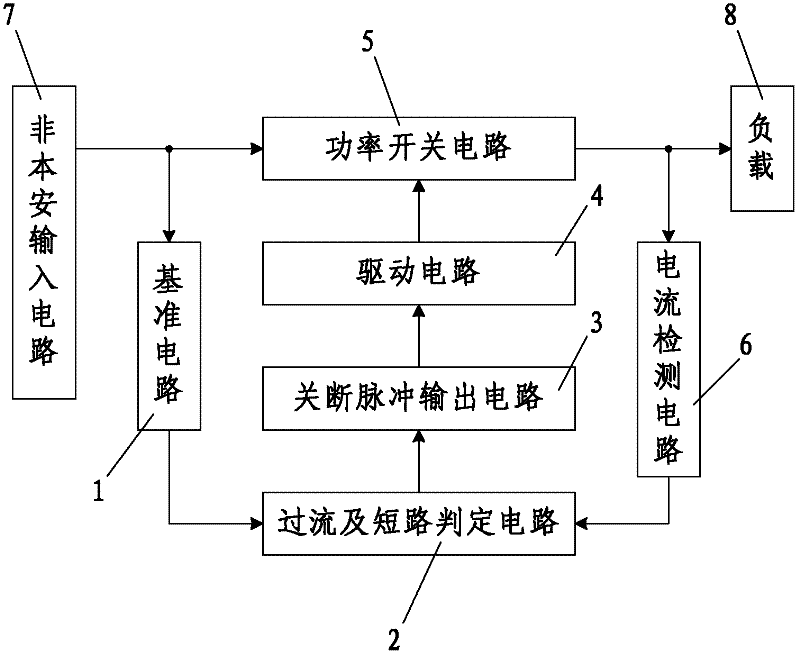

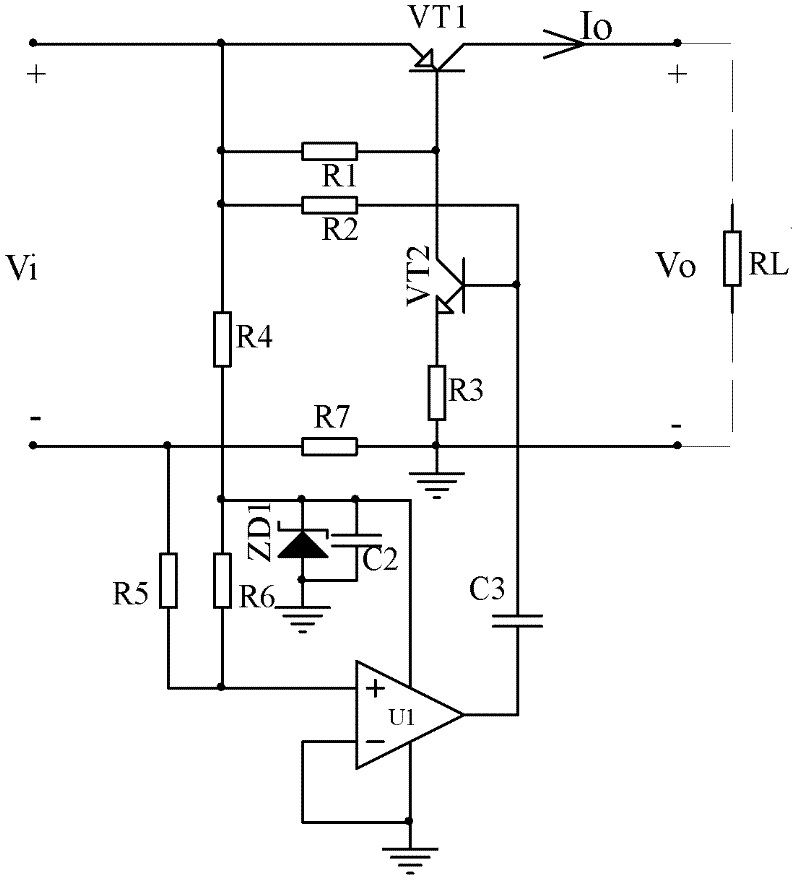

[0034] Such as figure 1 As shown, the present invention is connected between the non-intrinsically safe input circuit 7 and the load 8, including the power switch circuit 5 connected between the non-intrinsically safe input circuit 7 and the load 8 and used to control the opening or closing of the circuit, and the power switch The circuit 5 is connected with the current detection circuit 6 used for real-time detection of the magnitude of the current in the circuit, the overcurrent and short circuit judgment circuit 2 connected with the current detection circuit 6 and used for judging whether an overcurrent or short circuit occurs, and the overcurrent and short circuit The judgment circuit 2 is connected and used to output the shutdown pulse output circuit 3 when the overcurrent or short circuit occurs, and the shutdown pulse output circuit 3 is connected to the shutdown pulse output circuit 3 and is used to control the drive of the power switch circuit 5 to turn off or open. C...

Embodiment 2

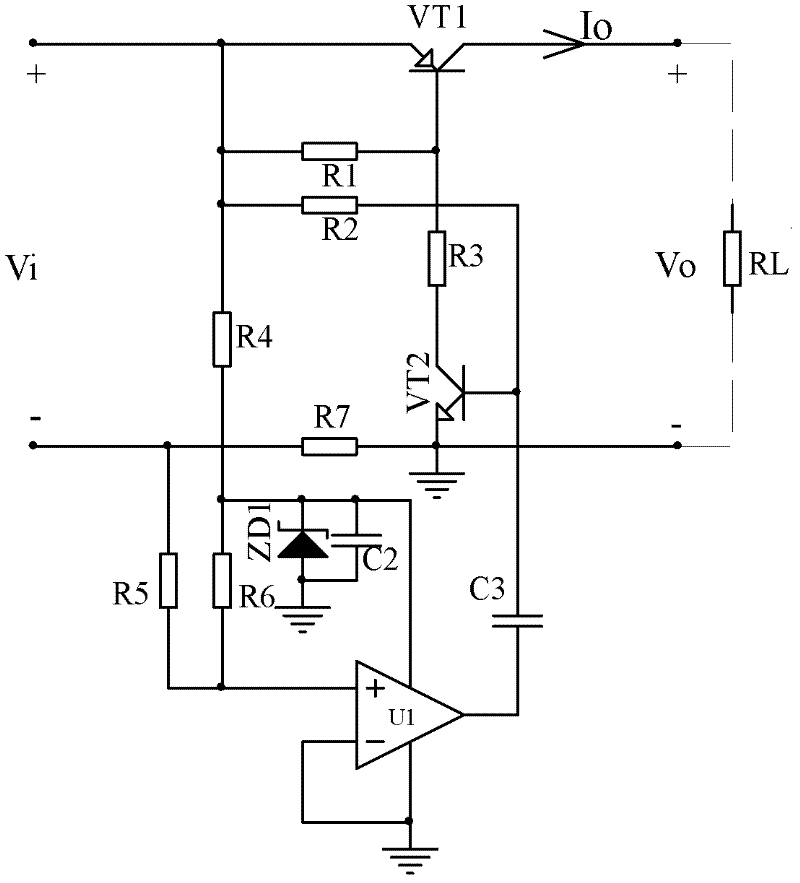

[0042] combine image 3 The difference between this embodiment and Embodiment 1 is that the emitter of the NPN transistor VT2 is grounded, the collector of the NPN transistor VT2 is connected to one end of the resistor R3, and the other end of the resistor R3 is a drive circuit 4 output terminals. The rest of the circuit structure is the same as that of Embodiment 1.

Embodiment 3

[0044] combine Figure 4 The difference between this embodiment and Embodiment 1 is that the power switch circuit 5 includes a resistor R1 and an enhanced PMOS transistor VT3, and one end of the resistor R1 and the source of the enhanced PMOS transistor VT3 are connected to the non-intrinsically safe input circuit The positive output end of 7 is connected, the other end of the resistor R1 is connected to the gate of the enhanced PMOS transistor VT3 and connected to the output end of the drive circuit 4, and the drain of the enhanced PMOS transistor VT3 is a power switch circuit The positive output terminal of 5 is connected with the positive pole of the load 8. The rest of the circuit structure is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com