Testing equipment for rearview mirror adjusting switch circuit board

A technology for adjusting switches and testing equipment, which is applied in the direction of electronic circuit testing, etc., can solve problems such as low efficiency and waste of labor, and achieve the effect of saving labor and improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

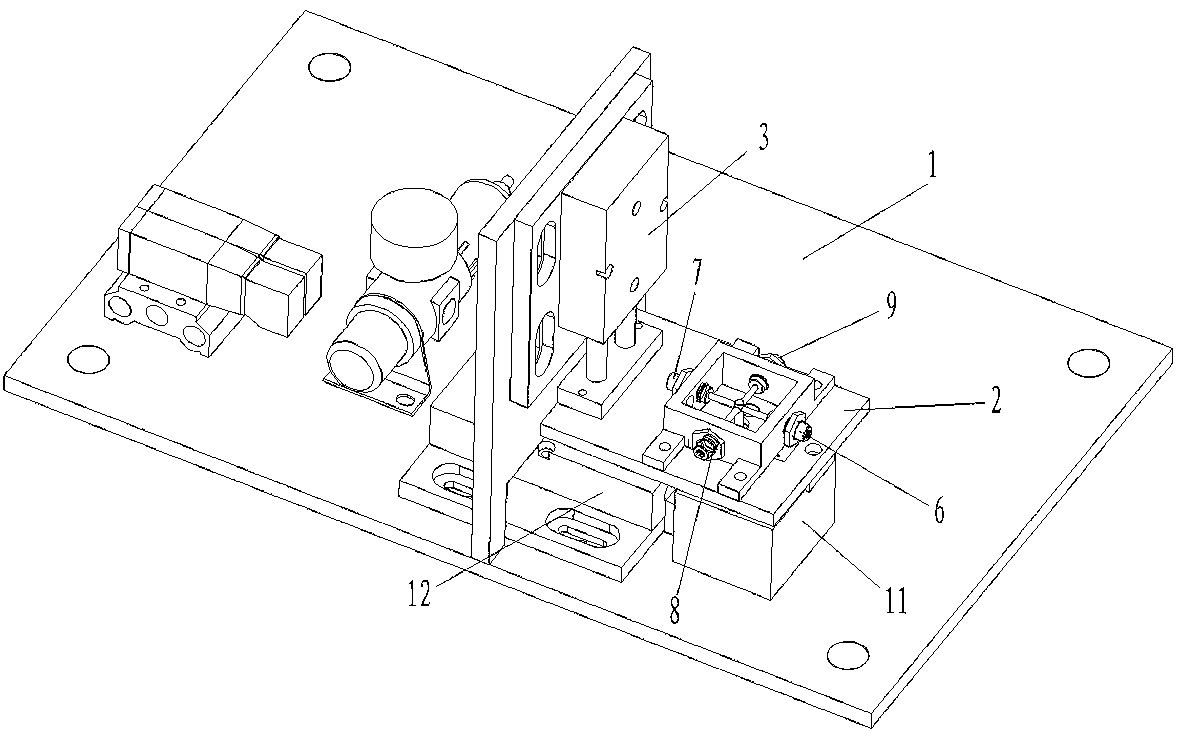

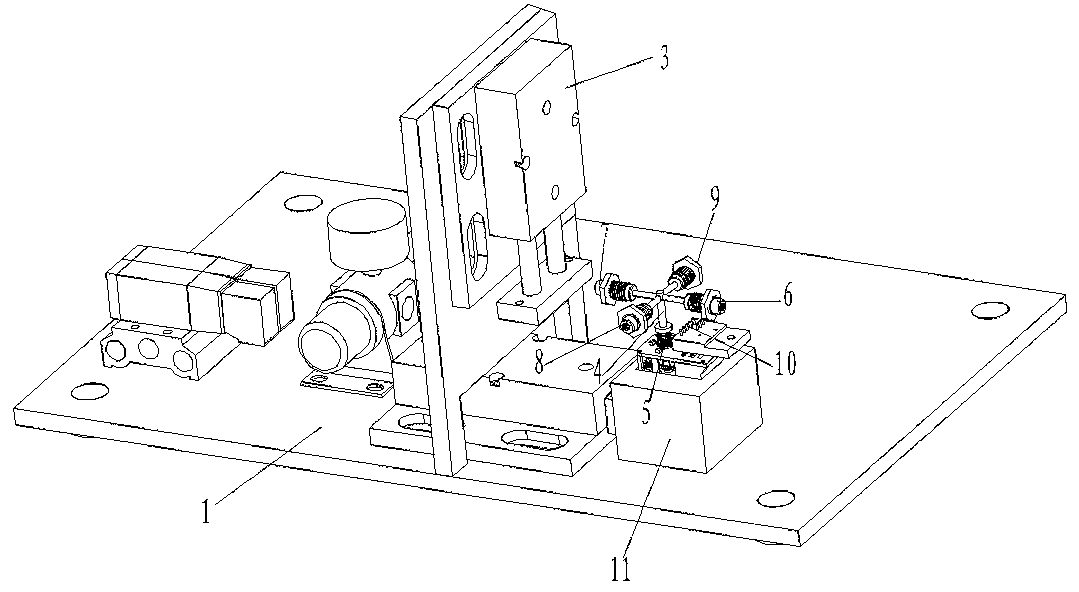

[0015] refer to figure 1 , figure 2 , a kind of testing equipment of rearview mirror adjustment switch circuit board, comprises frame 1, and described frame 1 is provided with the horizontal test platform 2 that can slide up and down, and described frame 1 is also provided with vertical The lift cylinder 3, the piston rod of the lift cylinder 3 is connected with the test bench 2.

[0016] The test bench 2 is pierced with a lever 4 that can be moved forward, backward, left, and right through the test bench. On the above-mentioned spherical hinge, to realize the function of shifting lever 4 forward, backward, left, and right. In this embodiment, a spring 5 is sheathed on the lever 4 , and the spring 5 is located below the test platform 2 .

[0017] The outside of the driving rod 4 is also provided with a forward push cylinder 6, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com