Support control device for hydraulic support

A technology of hydraulic supports and control devices, which is applied in mine roof supports, mining equipment, earthwork drilling and mining, etc. It can solve the problems of poor matching of resources, heavy workload of cable connectors, idleness, etc., and improve the utilization of resources Efficiency and convenient system maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

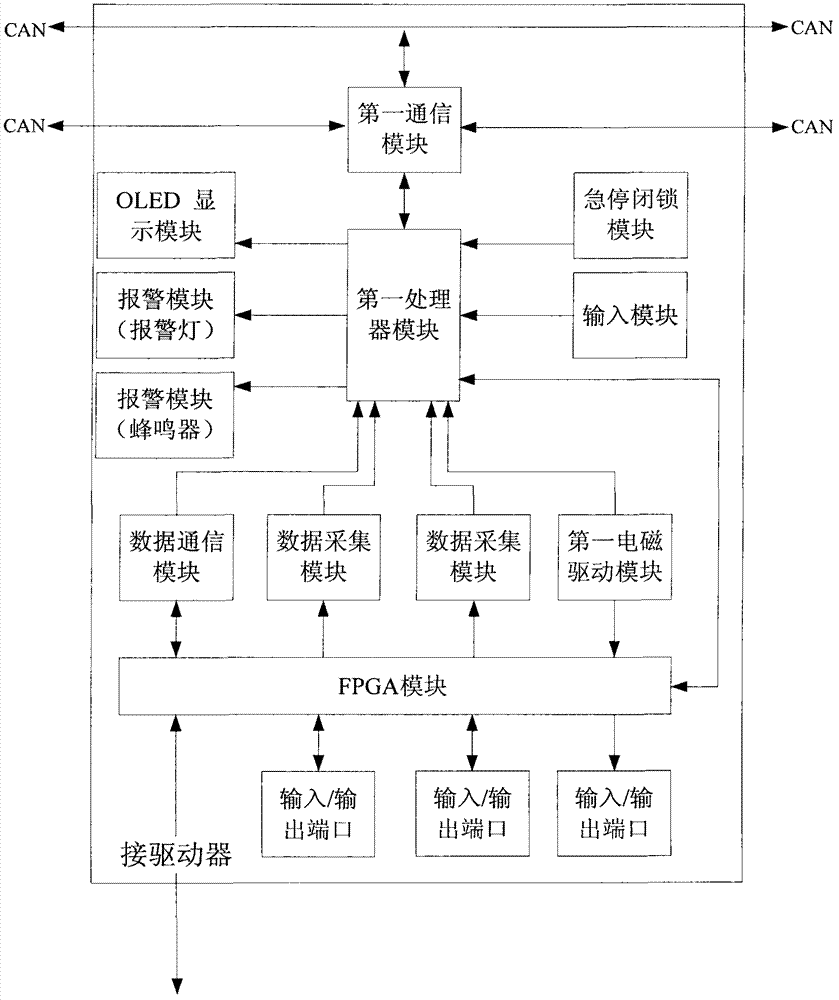

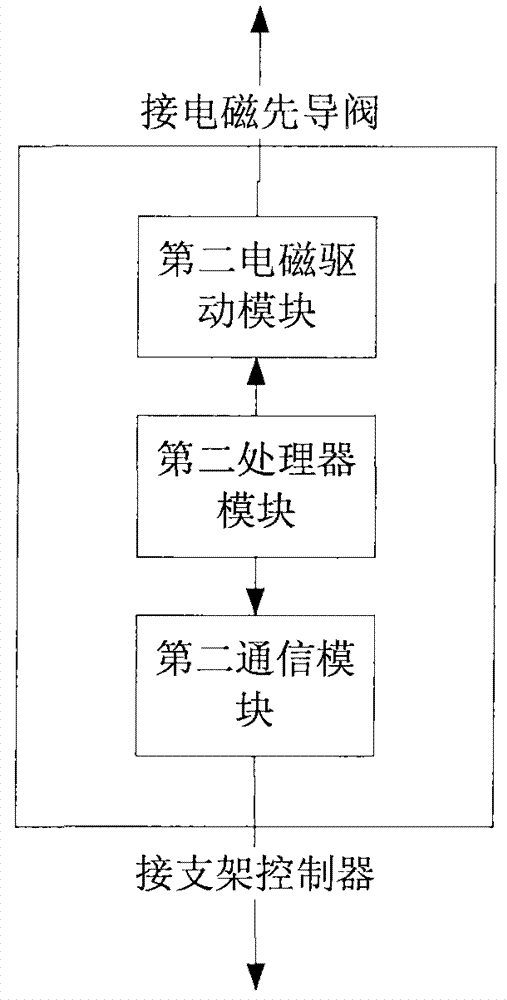

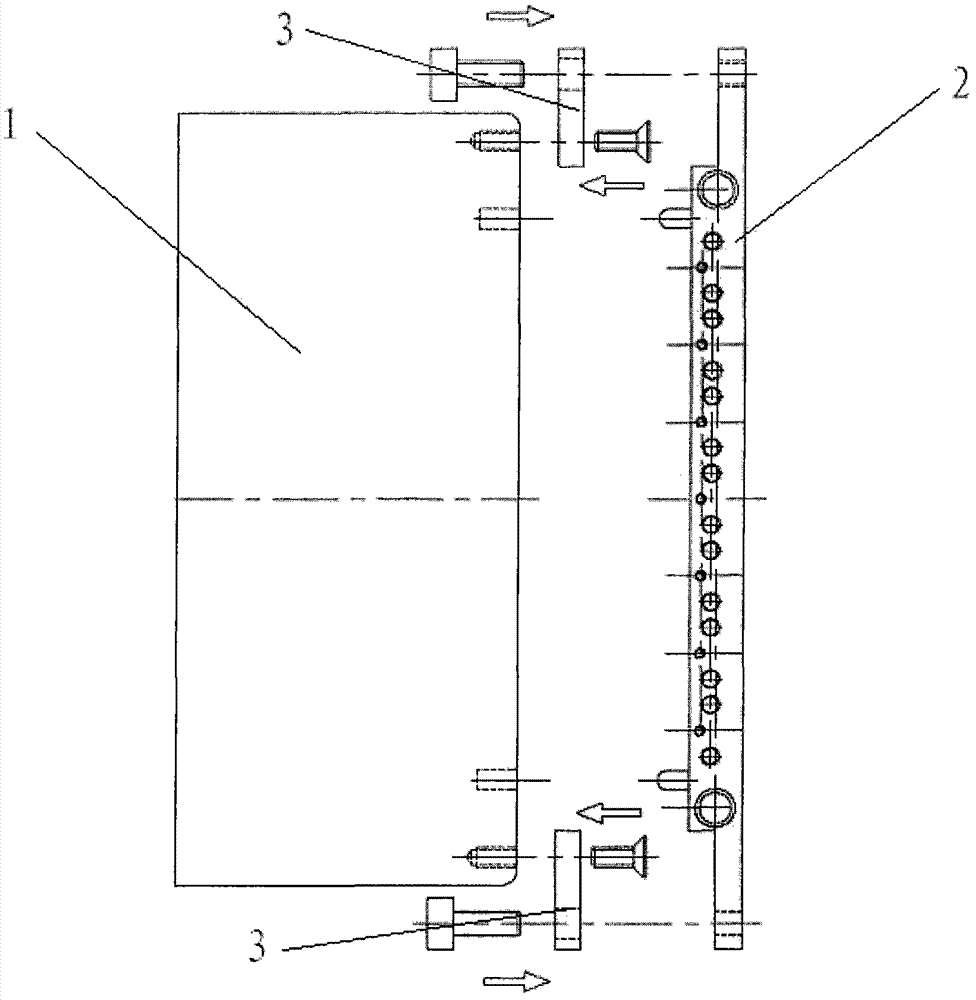

[0027] See attached figure 1 , a support control device, including a support controller and a driver, the support controller is installed on the hydraulic support, the support controller includes a processor module, a communication module, an input module, a data acquisition module, an OLED display module, an alarm Module, data communication module, emergency stop locking module and FPGA module, described communication module, input module, data acquisition module, OLED display module, alarm module, data communication module, emergency stop locking module and FPGA module are connected with processor module respectively ; The communication module includes three-way CAN buses, two of which are connected to the support controllers of the left and right adjacent hydraulic supports for data communication between adjacent support controllers, and the other CAN bus is connected to the CAN bus on the working surface. The CAN bus of the working surface is a bus that runs through the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com