Supporting process in soft rock mine roadway rush through construction tunneling

A coal roadway, fast technology, applied in the direction of temporary shields, pillars/brackets, mining equipment, etc., can solve problems such as failure, roadway deformation support, etc., and achieve the effect of long stabilization time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

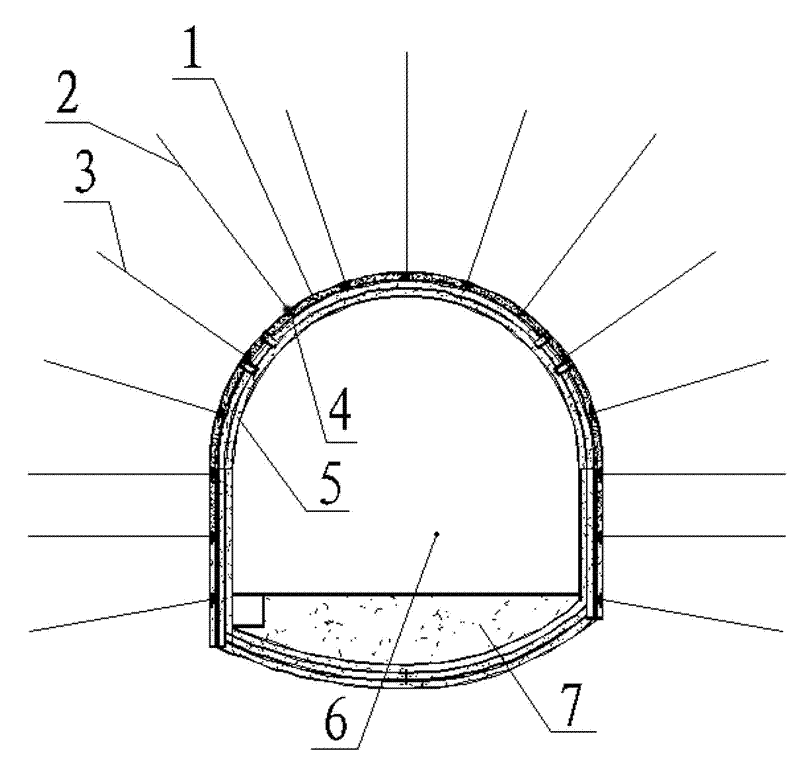

[0017] The average thickness of the coal seam in Changping Mine of Shanxi Coal Group is 5.6m, the coal seam dip angle is 2-10°, the average is 6°, black, metallic luster, endogenous cracks are developed, bright coal is mainly contained, dark coal, semi-bright briquette, intercalated Gangue is mudstone, brittle, low-sulfur, high-quality anthracite coal with high calorific value. A fault was encountered during the tunneling of a fully-mechanized mining face, and the roadway was affected by the fault structure with high ore pressure, rapid pressure, and poor self-stability. After the roadway was excavated, the surrounding rock deformed rapidly, the self-stabilization time was short, and the mine pressure appeared violently. The roadway support was extremely difficult, and normal excavation could not be carried out.

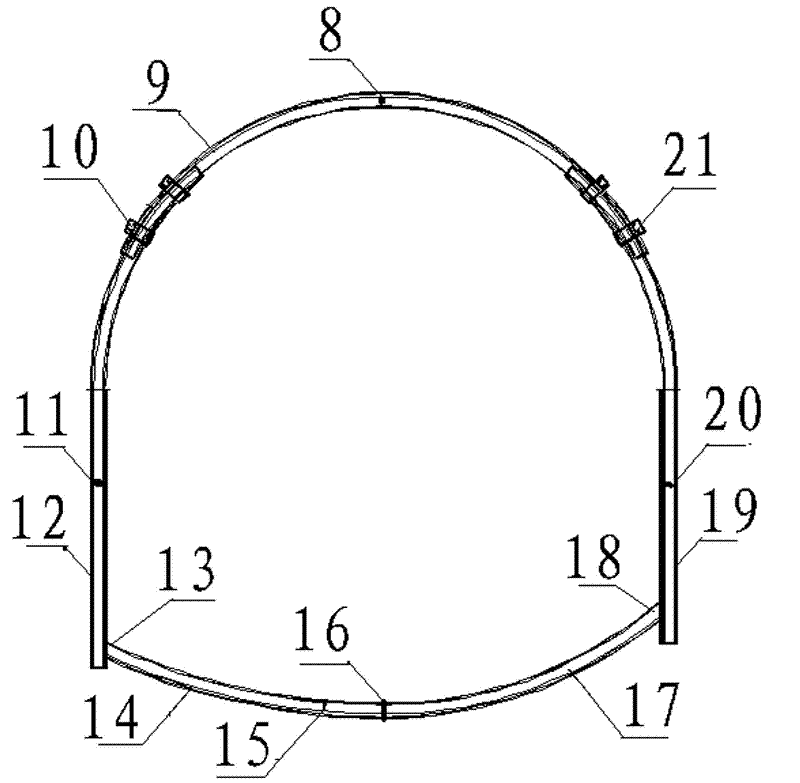

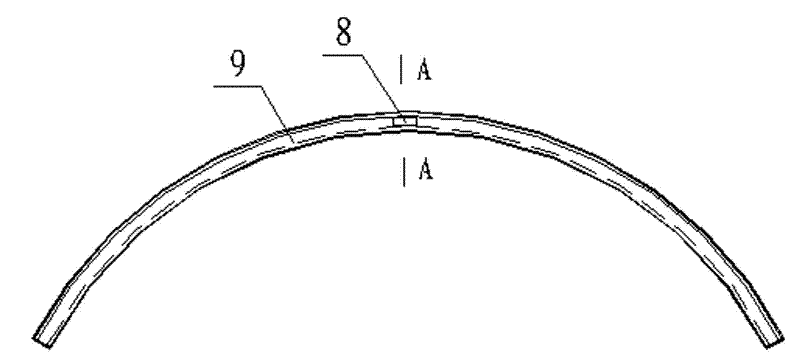

[0018] In order to solve this problem, the support adopts the following technical means, such as figure 1 As shown, after the roadway is excavated, the metal mesh 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com