Medical silicon rubber with modified hydrophilic structure on surface, and preparation and application of medical silicon rubber

A hydrophilic structure, silicone rubber technology, used in medical science, surgery, etc., can solve the problems of not reducing the modification effect, reducing cost, high price, etc., reducing adsorption and cell adhesion, improving biocompatibility, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

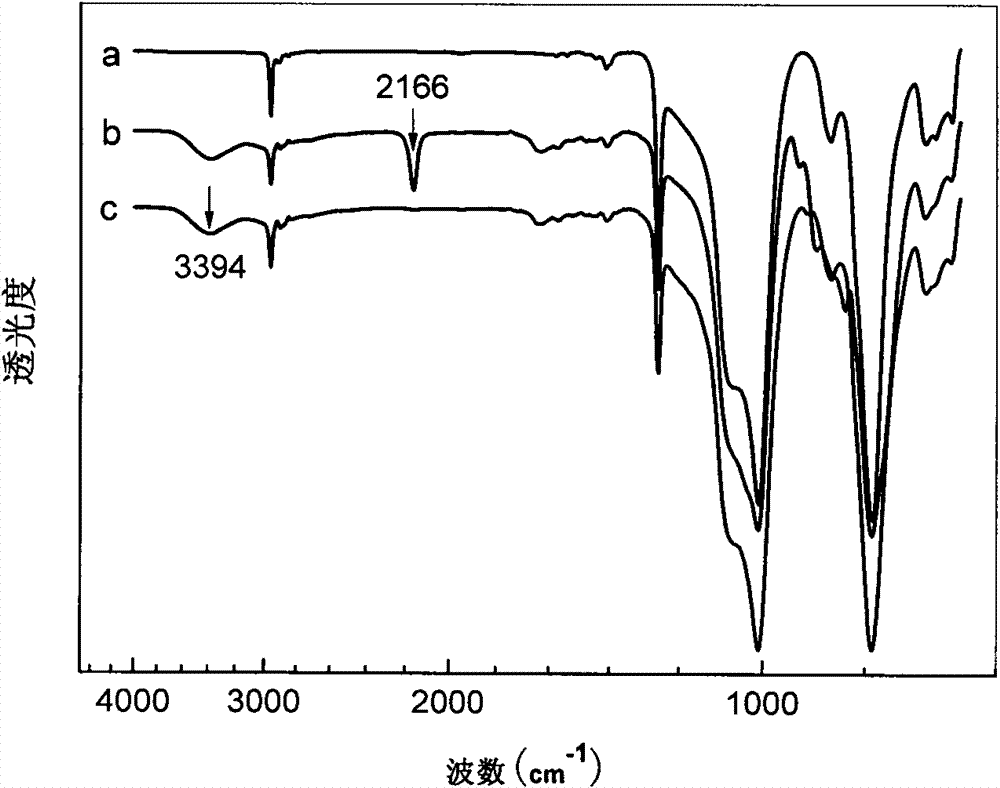

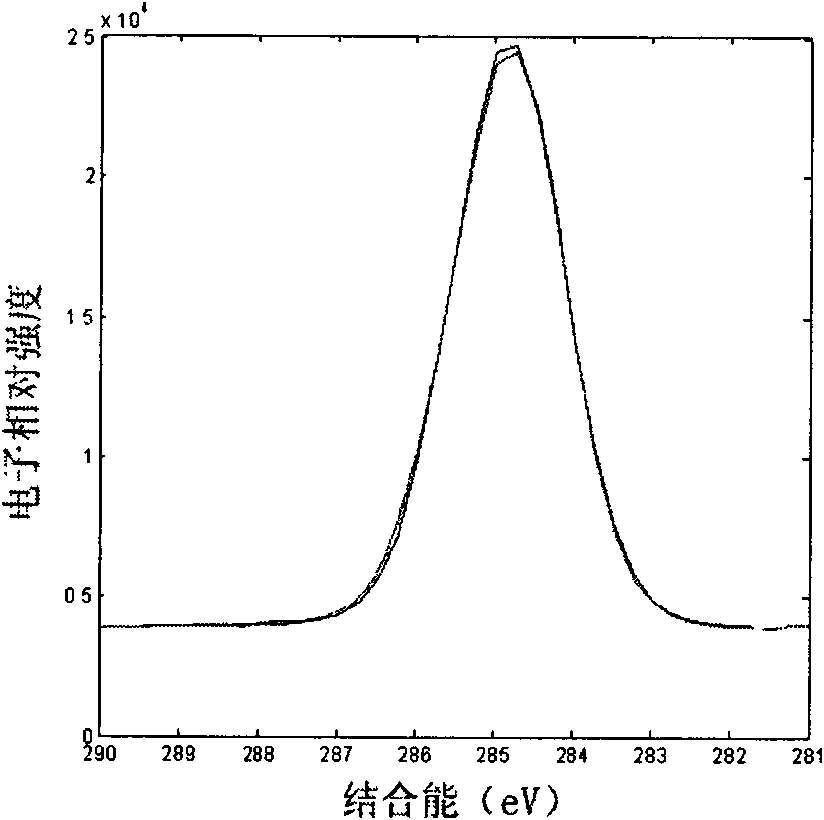

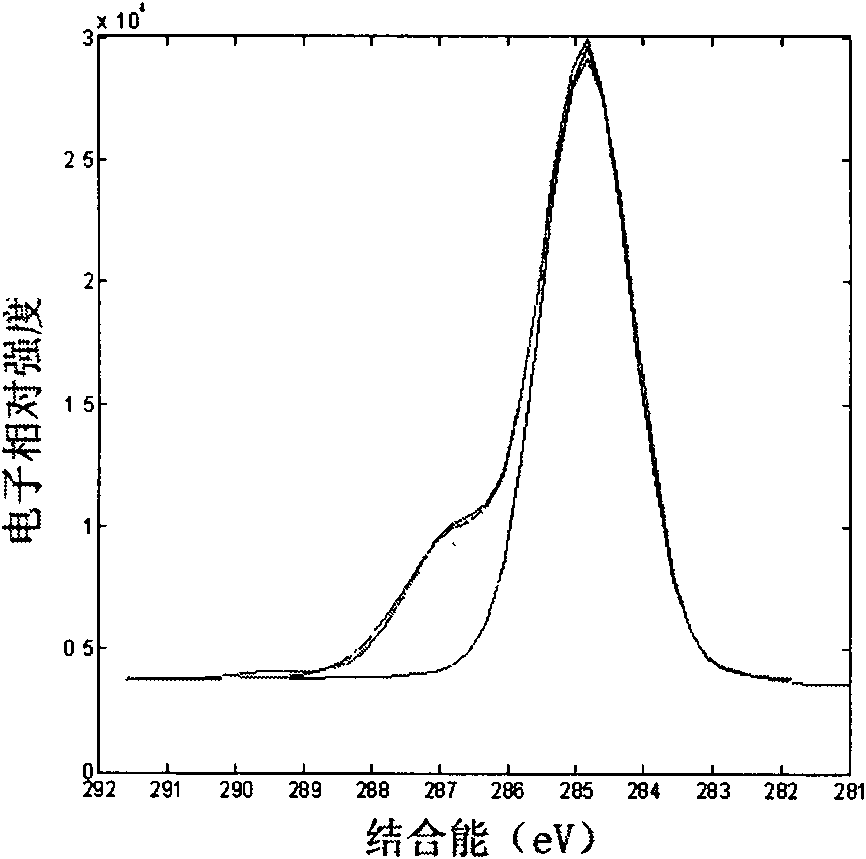

[0025] (1) Measure 4.5mL of polymethylhydrogensiloxane solution and 7.5mL of anhydrous methanol solution, and magnetically stir to form a mixed solution. Place a medical silicone rubber block with a size of 4mm×2.5mm×0.7mm in the mixed solution of polymethylhydrogensiloxane and anhydrous methanol, then add 0.04mL trifluoromethanesulfonic acid, seal the reaction device, and The reaction was stirred magnetically for 75 minutes at room temperature. After the reaction was completed, the medical silicone rubber sample was thoroughly washed with an appropriate amount of n-hexane solution and anhydrous methanol solution, and dried in vacuum for 1 day to obtain a medical silicone rubber sample with Si-H active groups on the surface.

[0026] (2) Measure 11.38 mL of polyethylene glycol methyl ether acrylate solution with a molecular weight of 480 kD and 3.63 mL of isopropanol solution, and stir magnetically to form a mixed solution. Place the surface-functionalized medical silicone ru...

Embodiment 2

[0029] The raw materials and preparation method are similar to Example 1, except that the amount of polymethylhydrogensiloxane and anhydrous methanol is changed from 4.5mL and 7.5mL to 5mL and 10mL, and the dynamic contact of the prepared surface hydrophilic medical silicone rubber The angle is 110.6°.

Embodiment 3

[0031] The raw materials and preparation method are similar to those in Example 2, except that polymethylhydrogensiloxane, the amount of anhydrous methanol is changed from 5mL and 10mL to 5mL and 15mL, and the dynamic contact angle of the prepared surface hydrophilic medical silicone rubber is 112.4°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com