Airship sheath material and preparation method thereof

A skin material and airship technology, which is applied in the field of airship skin materials and its preparation, can solve the problems of barrier materials such as poor water resistance and no weight advantage, and achieve the effects of good processing performance, improved rubbing resistance, and improved barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

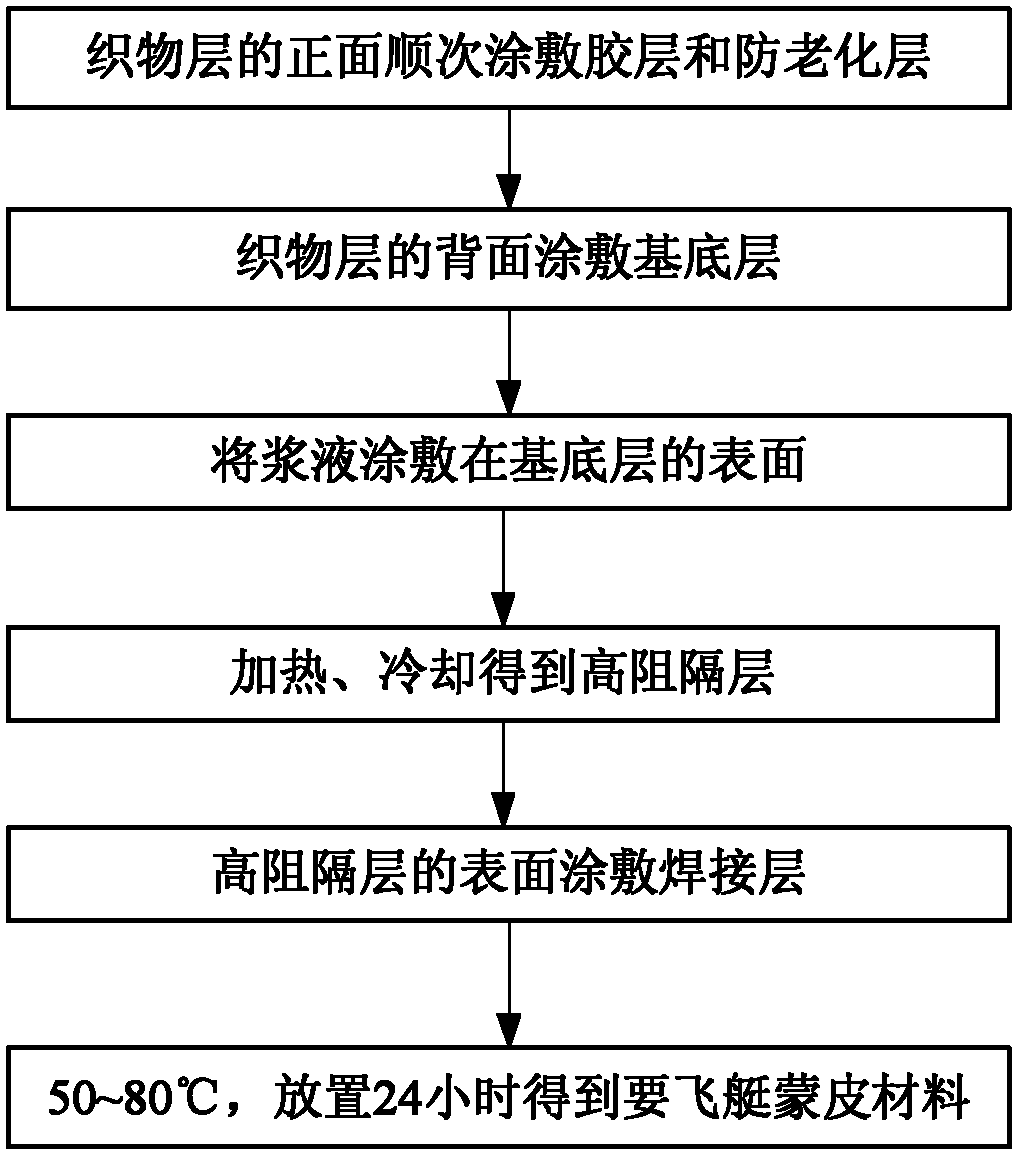

[0024] A kind of preparation method of airship skin material that the present invention proposes, such as figure 2 As shown, it specifically includes the following steps:

[0025] Step 1: Firstly, a 20-25 micron-thick glue layer and a 25-35 micron-thick anti-aging layer are sequentially coated on the front side (direct sunlight surface) of the fabric layer with a thickness of 100-150 microns.

[0026] The fabric layer is made of polyester, aramid or other high-strength fibers. The material of the adhesive layer is hot-melt polyurethane adhesive or coated polyurethane adhesive. The anti-aging layer contains 1-3% ZnO and 2.5-4% TiO 2 thermoplastic polyurethane.

[0027] Step 2: Coat the back of the fabric layer with a base layer with a thickness of 25-30 microns, and dry it above 80°C to form a smooth film on the surface. The material of the base layer is a thermoplastic polyurethane layer.

[0028] Step 3: adding polyvinyl alcohol (with a purity of 100%) to the purified di...

Embodiment 1

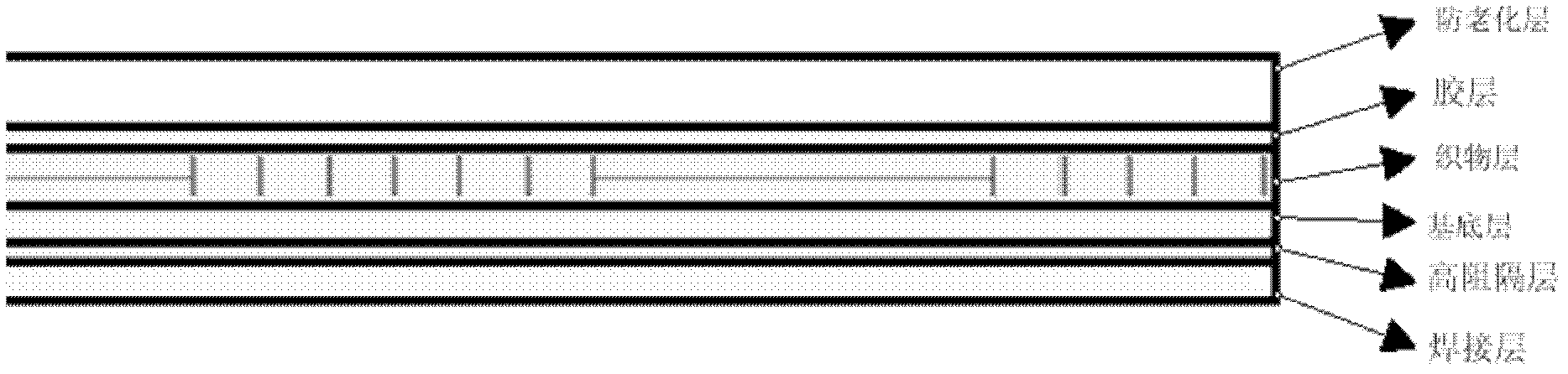

[0035] This embodiment provides a kind of airship skin material, and this skin material is made up of six-layer structure, is anti-aging layer, adhesive layer, fabric layer, base layer, high barrier layer and welding layer successively from top to bottom; The thickness of the anti-aging layer is shown in Table 1. The material of the anti-aging layer is 1% ZnO and 2.5% TiO 2 thermoplastic polyurethane with a thickness of 30 microns; the material of the adhesive layer is hot-melt polyurethane adhesive with a thickness of 25 microns; the material of the fabric layer is aramid fiber cloth with a thickness of 105 microns; the material of the base layer is thermoplastic polyurethane, The thickness is 30 microns; the material of the high barrier layer is SiO with a mass fraction of 1.5% and a particle size of 20-60nm 2 Nanoparticles of polyvinyl alcohol, 1 micron thick. The material of the welding layer is thermoplastic polyurethane with a thickness of 20 microns.

[0036] Table 1 ...

Embodiment 2

[0047] This embodiment provides a kind of airship skin material, and this skin material is made up of six-layer structure, is anti-aging layer, adhesive layer, fabric layer, base layer, high barrier layer and welding layer successively from top to bottom; Anti-aging The material of the layer is 3% ZnO and 4% TiO 2 thermoplastic polyurethane with a thickness of 25 microns; the material of the adhesive layer is hot-melt polyurethane adhesive or coated polyurethane adhesive with a thickness of 25 microns; the material of the fabric layer is polyester fiber with a thickness of 100 microns; the base layer The material is thermoplastic polyurethane with a thickness of 25 microns; the material of the high barrier layer is SiO with a mass fraction of 2.5% and a particle size of 40-70nm 2 Nanoparticles of polyvinyl alcohol with a thickness of 3 microns. The material of the welding layer is thermoplastic polyurethane with a thickness of 30 microns.

[0048] The invention provides a me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com