Forced casting cooling system

A technology of forced cooling and casting, applied in the field of cooling system, can solve the problem of increased floor space or space, and achieve the effect of saving floor space, improving cooling effect and shortening cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

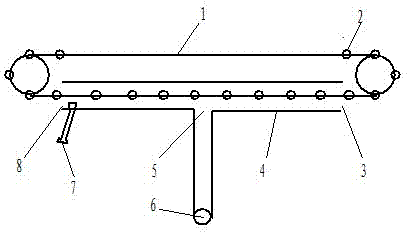

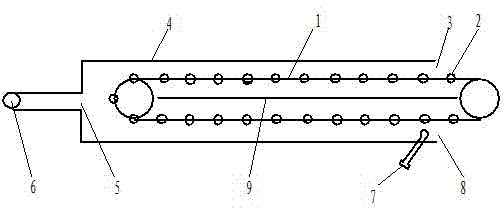

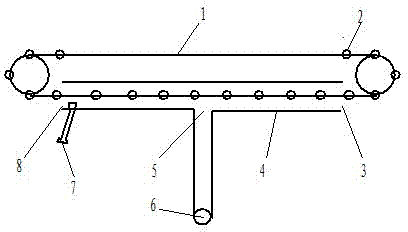

[0015] figure 1 It is a structural schematic diagram of the first technical solution of the casting forced cooling system; figure 1 As shown, the system includes a semi-sealed cover 4 with a cylindrical structure; the front and rear ends of the semi-sealed cover 4 are open structures, the opening at the front end is the entrance 3, and the opening at the rear end is the exit 8; the casting conveying line 1 passes through the entrance 3 And the outlet 8 passes through the semi-sealed cover 4. The middle part of the semi-sealed cover 4 of this system is provided with an air exhaust port 5, and the air exhaust port 5 is connected with an electric induced draft fan 6. The system is provided with a temperature sensor 7 at the outlet 8 of the semi-sealed cover 4, and the electrical signal of the temperature sensor 7 controls the speed of the electric induced draft fan through a frequency converter, thereby changing the exhaust air volume of the electric induced draft fan 6.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com