High-efficiency energy-saving motor

A high-efficiency, energy-saving, casing technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of lag closure, high magnetic field on both sides of the motor, and inability to use magnetic energy reasonably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

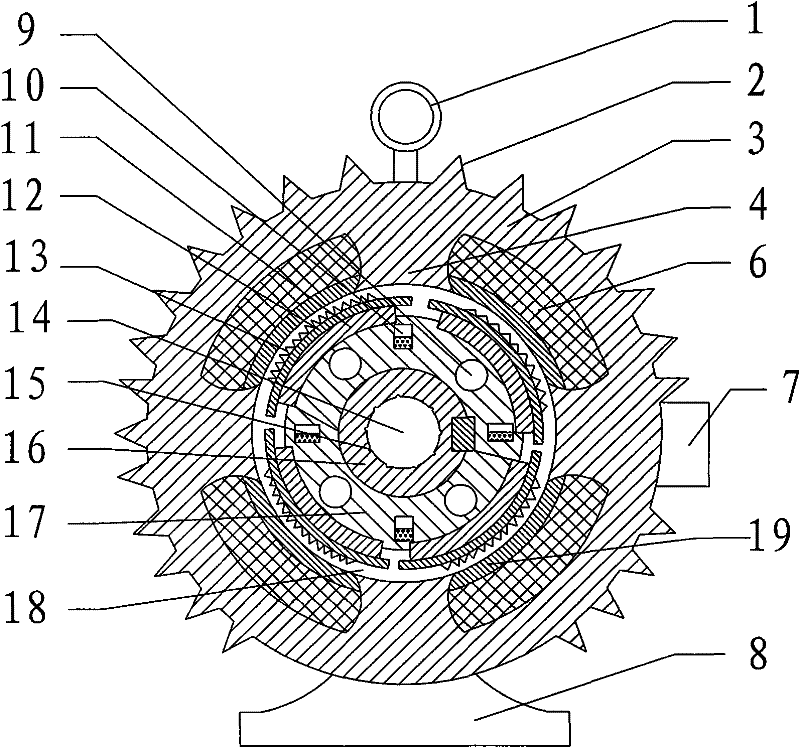

[0017] Such as figure 1 As shown, a high-efficiency energy-saving motor has an organic casing 3, a stator, a rotor, and a base 8 connected with the casing 3. The waterproof outlet device 7, the rotor includes a rotor mandrel 16 and a hollow rotor body 17, the hollow rotor body 17 is fixed on the rotor mandrel 16, it is characterized in that the rotor mandrel 16 has a concentric shaft hole 14, and the wall of the shaft hole 14 There are spiral grooves 15, and the rotor body 17 is evenly distributed with holes 9 parallel to the rotor mandrel 16. The outer circumference of the rotor body 17 is inlaid with geometrically shaped permanent magnet materials 11, and the surface of the rotor body 17 is provided with geometrically shaped permanent magnet materials. 11. Part is embedded in the rotor body 17, and part is exposed on the outer surface of the rotor body 17; the outer surface of the permanent magnetic material 11 is not lower than the outer surface of the rotor body, and the o...

Embodiment 2

[0019] Such as figure 2 As shown, a high-efficiency energy-saving motor has an organic casing 3, a stator, a rotor, and a base 8 connected with the casing 3. The waterproof outlet device 7, the rotor includes a rotor mandrel 16 and a hollow rotor body 17, the hollow rotor body 17 is fixed on the rotor mandrel 16, it is characterized in that the rotor mandrel 16 has a concentric shaft hole 14, and the wall of the shaft hole 14 There are spiral grooves 15, and the rotor body 17 is evenly distributed with holes 9 parallel to the rotor mandrel 16. The outer circumference of the rotor body 17 is inlaid with geometrically shaped permanent magnet materials 11, and the surface of the rotor body 17 is provided with geometrically shaped permanent magnet materials. 11. Part is embedded in the rotor body 17, and part is exposed on the outer surface of the rotor body 17; the outer surface of the permanent magnetic material 11 is not lower than the outer surface of the rotor body, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com