Cable connector component

A cable connector and component technology, applied in the direction of connection, connecting device parts, fixed connection, etc., can solve the problem of high overall height of cable connector components, achieve structure miniaturization, prevent electromagnetic interference, and reduce overall height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

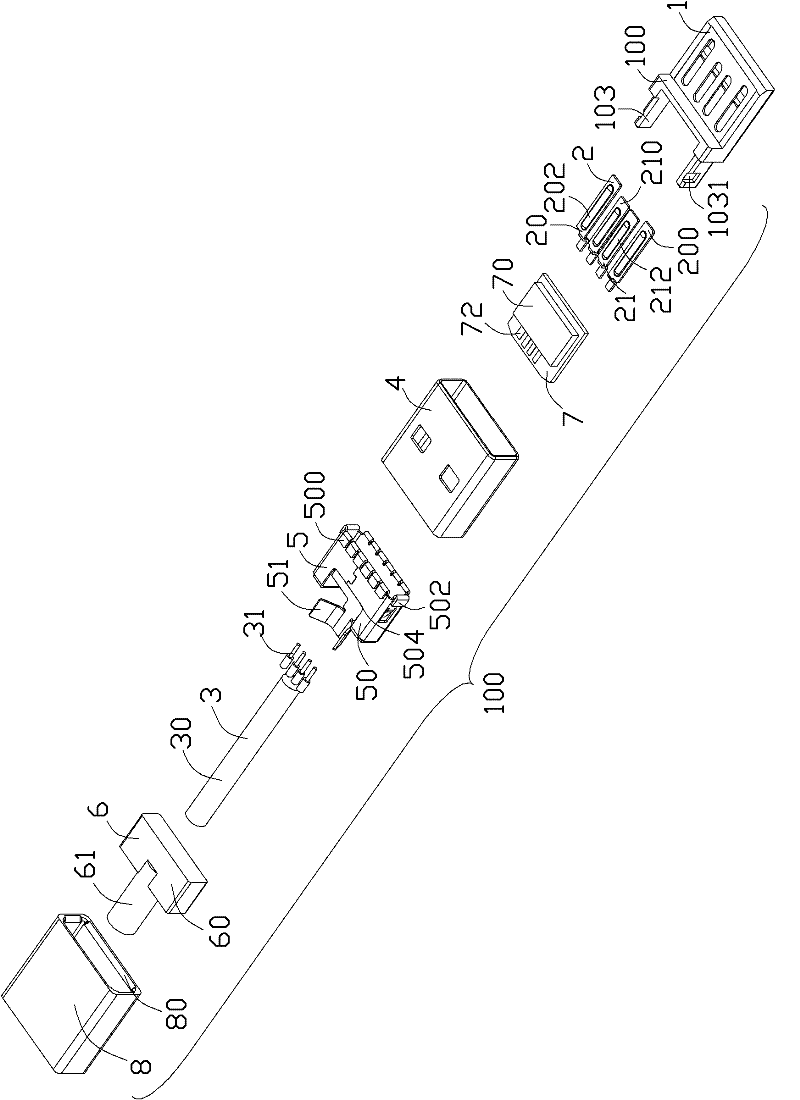

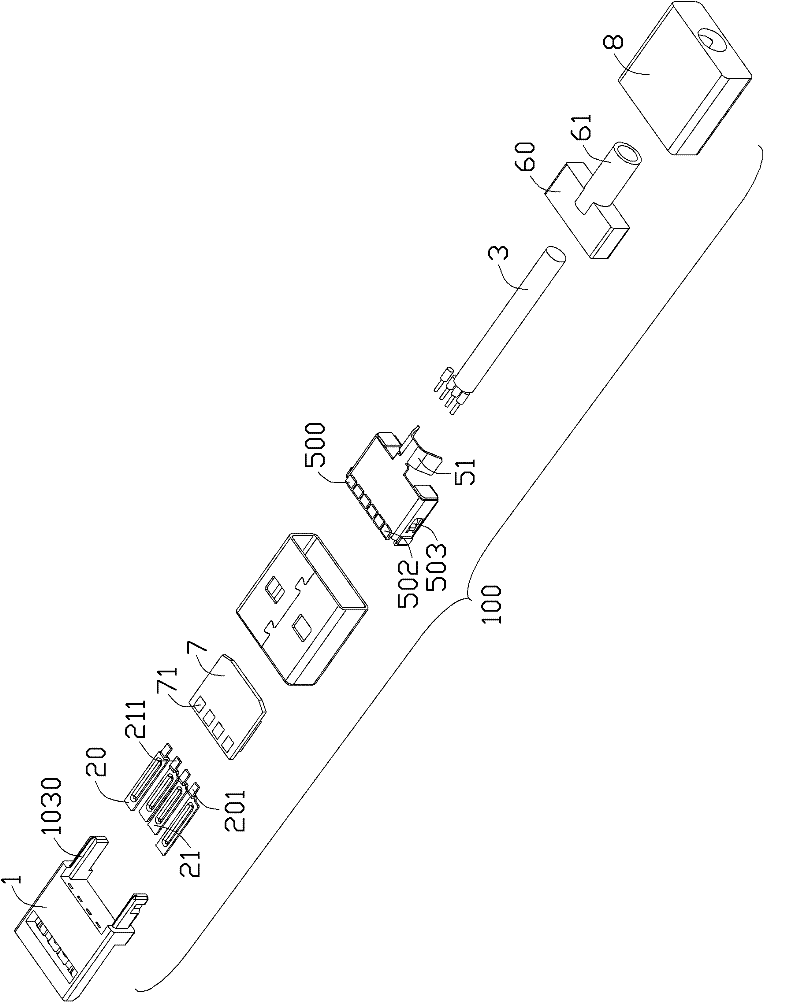

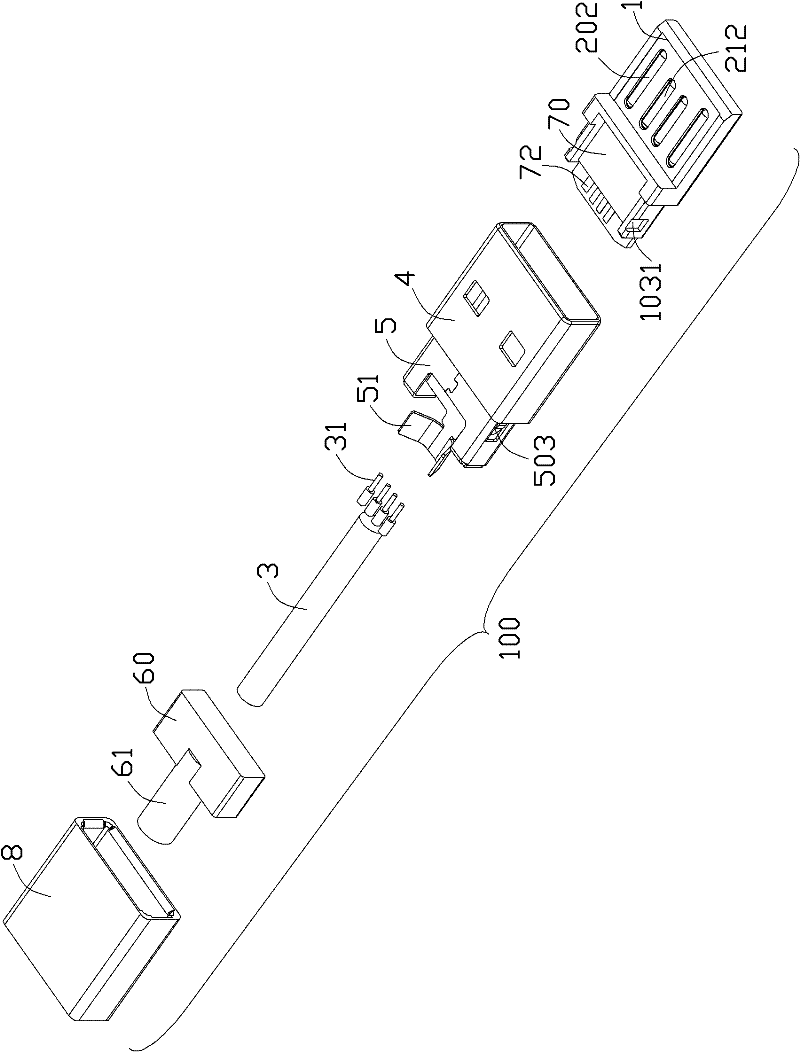

[0013] The cable connector assembly 100 of the present invention includes a conductive terminal 2, an insulating body 1 formed on the periphery of the conductive terminal 2, a cable 3 electrically connected to the conductive terminal 2, and a metal covering the outer periphery of the insulating body 1. The outer shell 4 and the metal inner shell 5 arranged behind the metal outer shell 4 .

[0014] Please refer to Figure 1 to Figure 2 As shown, the insulator body 1 is roughly in the shape of a cuboid, and the insulator body 1 includes a flat plate portion 100 located in front of it and shielded inside the metal shell 4, and left and right sides from the rear surface of the flat plate portion 100. The cantilever 103 formed by extending laterally and rearwardly is shielded inside the metal inner shell 5 . From the inner side wall of the cantilever 103 near the lower surface of the cantilever 103 are respectively formed with slide grooves 1030 extending in the front and rear dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com