Power strip

A plug-and-socket technology, applied in the field of electrical equipment, can solve the problem of inability to plug multiple large-volume plugs, and achieve the effect of improving the utilization rate and avoiding mutual blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

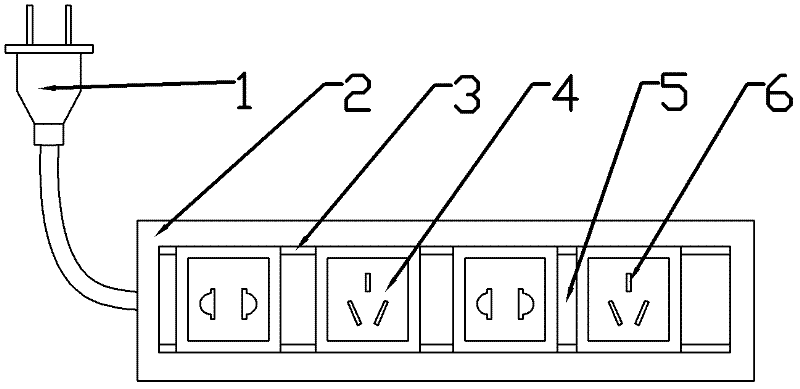

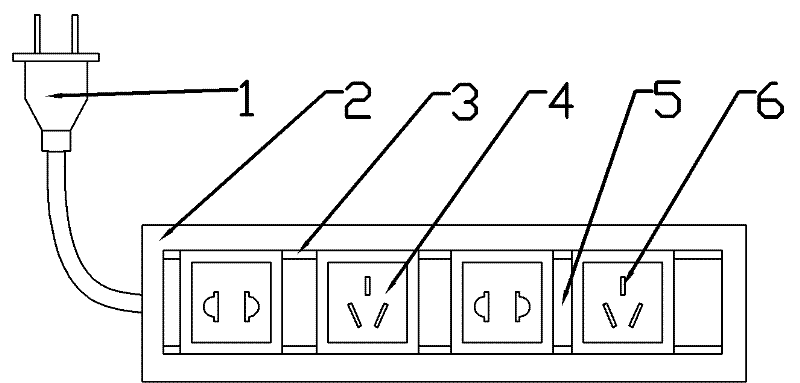

[0008] Such as figure 1 shown. A plug strip, its structure includes a power cord 1, a base 2 and a socket 4, the power cord 1 is connected to the socket 4 through the base 2, a groove 5 is provided in the base 2, and the two sides of the groove 5 Each side is provided with a sliding rail 3 parallel to each other, and a plurality of sockets 4 that are independent of each other and leave gaps are slid on the sliding rail 3, and each independent socket 4 can slide in the sliding rail 3, so that the socket 4 being used It has a relatively large space and is convenient for the use of large plugs. The sockets 4 are respectively provided with jacks 6 .

[0009] When the user uses a large-volume plug device on one or more groups of jacks 6, he can slide an adjacent socket 4 to the side for a certain distance, so as to avoid mutual shielding between the plugs, so that each set of jacks 6 can be used, and improve The utilization rate of the socket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com