Method for monitoring hole depth in drilling process of cable drill pipe

A drill pipe and hole depth technology, which is applied in the field of monitoring hole depth during wired drill pipe drilling, can solve the problems of not being able to detect the depth of drill pipe holes in real time, and achieve high-quality completion of drilling tasks with obvious effects and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

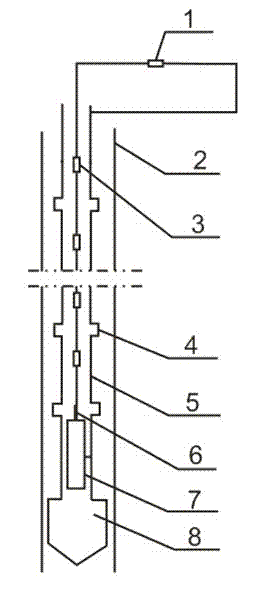

[0027] Embodiment 1: The method of the present invention is applied to the measurement of the hole depth in the drilling process of a large through-hole wired drill pipe that can measure the hole depth, and is measured according to the following steps:

[0028] ⑴. First, improve the existing common center-through cable-type high-strength large through-hole drill pipe, that is, insert a high-precision resistor 3 with the same resistance value at one end of the drill pipe through-hole cable in each large through-hole drill pipe; The drill pipe cable at the bottom is connected to the signal transmitting end of the probe tube 7, and the transmit signal is provided by a 12V DC level. The signal ground wire is connected to the lower drill pipe through the probe tube 7 bracket, and then connected to the ground resistance 1 to form a closed loop; Transform the ordinary central cable type high-strength large through-hole drill pipe into a large through-hole wired drill pipe with measura...

Embodiment 2

[0035] Embodiment 2: The method for monitoring hole depth in the drilling process of the present invention is the same as that of Embodiment 1, except that the resistance value of the ground resistance 1 and the selection of the high-precision resistance 3 in the drill pipe are different. The resistance value of ground resistance 1 is selected as 10kΩ.

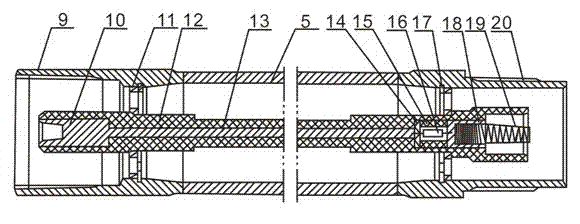

[0036] Selection of high-precision resistance in the drill pipe: according to the size of the cable male joint 18, two identical conductive circular metal sheets 21 and a polymer resin insulating ring 15 are made. see image 3 , the metal sheet 21 is made of copper with very low resistivity, and its thickness is 5 mm. The height of the polymer resin insulating ring 15 is 12mm, and its central through hole accommodates the in-line high-precision resistor 16, and the resistance value of the in-line high-precision resistor is selected as 1kΩ. The in-line high-precision resistor 16 is placed in the polymer resin insulating ring ...

Embodiment 3

[0037] Embodiment 3: The method for monitoring the hole depth during the drilling process of the present invention is the same as that of Embodiment 1, the difference is the resistance value of ground resistance 1 and the selection of high-precision resistance in the drill pipe. The resistance value of ground resistance 1 is selected as 20kΩ;

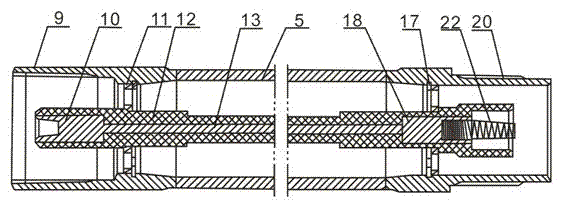

[0038] Selection of high-precision resistors in the drill pipe: According to the size of the variable diameter spring 19 in the center-through cable-type high-strength large through-hole drill pipe, spring resistors 22 of equal size are made. see Figure 4 , the resistance value of the spring resistor 22 is 150Ω, and the variable diameter spring 19 is replaced with a spring rheostat 22 under the condition that the spring resistor 22 has sufficient strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance value | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com