High-cleanness multilayer chip scraping device

A clean and saddle technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as reduced service life of machine tools, scratches on guide rail surfaces, unstable machining accuracy, etc., and prolong service life , to meet the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

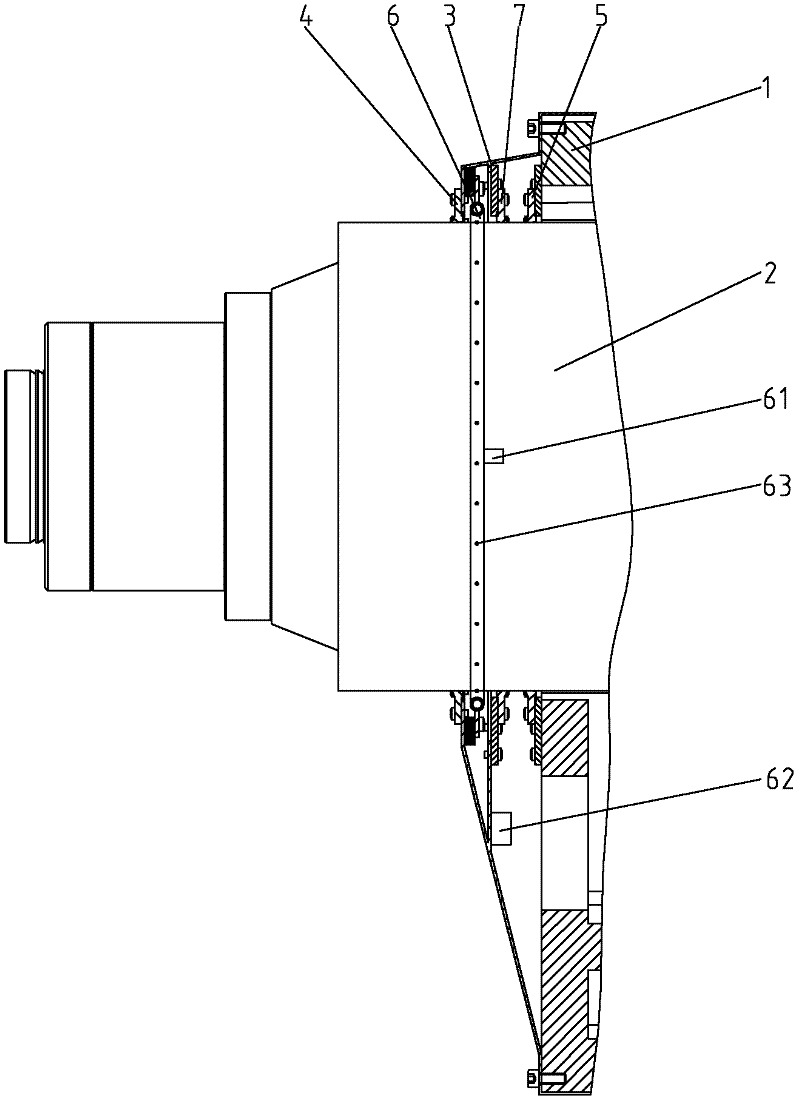

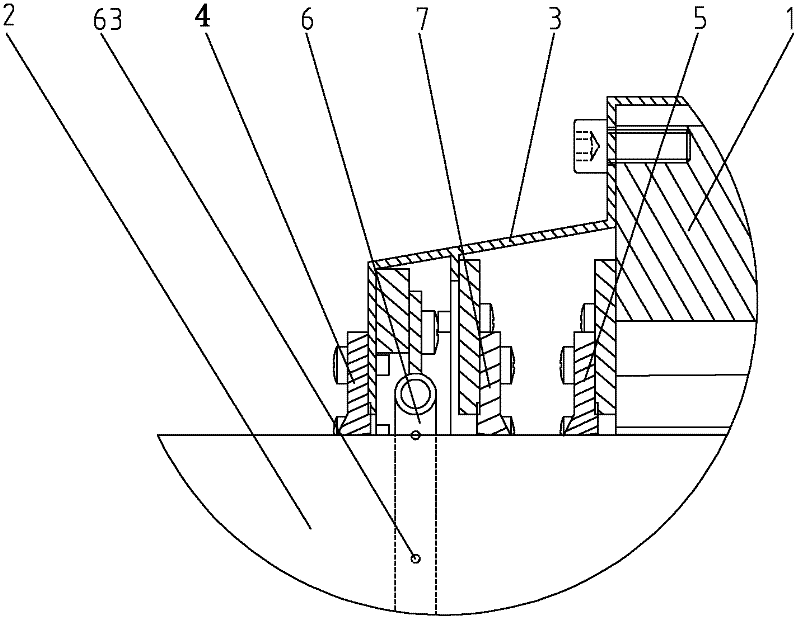

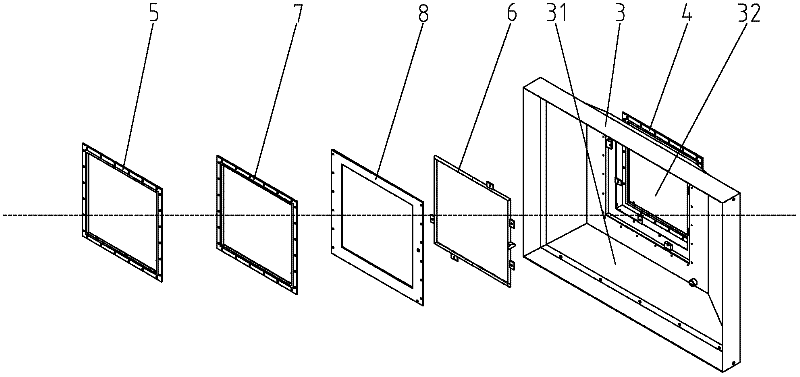

[0014] Such as Figure 1-4 As shown in one, the present invention includes a saddle 1, a ram 2 and a saddle cover 3, the ram 2 is set in the saddle 1 and extends out of the saddle 1, the saddle cover 3 is open at both ends and hollow The funnel shape of the saddle cover 3, an opening 31 end is fixed on the end surface of the saddle 1, and the other opening 32 end is sleeved on the ram 2, and the saddle cover 3 is set on the outer end surface of the opening of the ram 2 to fix a The scraping sheet 4 set on the ram 2, the end surface of the ram 2 of the saddle 1 is extended to fix a scraping sheet 5 set on the ram 2, the space formed by the saddle cover 3 and the end surface of the saddle 1 The cavity is provided with a back-shaped cleaning tank 6 sleeved on the ram 2 , and the end surface of the back-shaped cleaning tank 6 is fixed on the inner end surface of the saddle cover 3 .

[0015] The cavity formed by the saddle cover 3 and the end face of the saddle 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com