Ball mill

A technology of ball mill and ball mill tank, which is applied in the direction of grain processing, etc., can solve the problems of structural connection, difficulty in realizing continuous operation requirements of production process, etc., and achieve the effect of realizing continuity and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

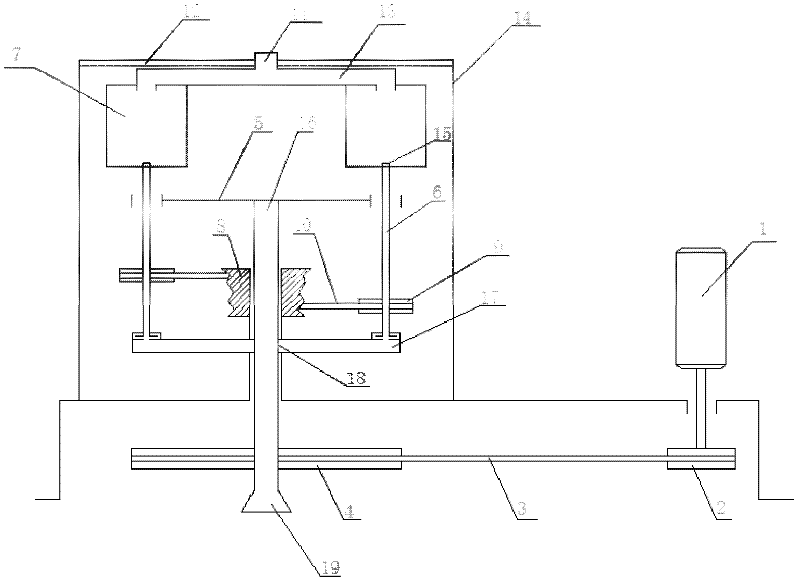

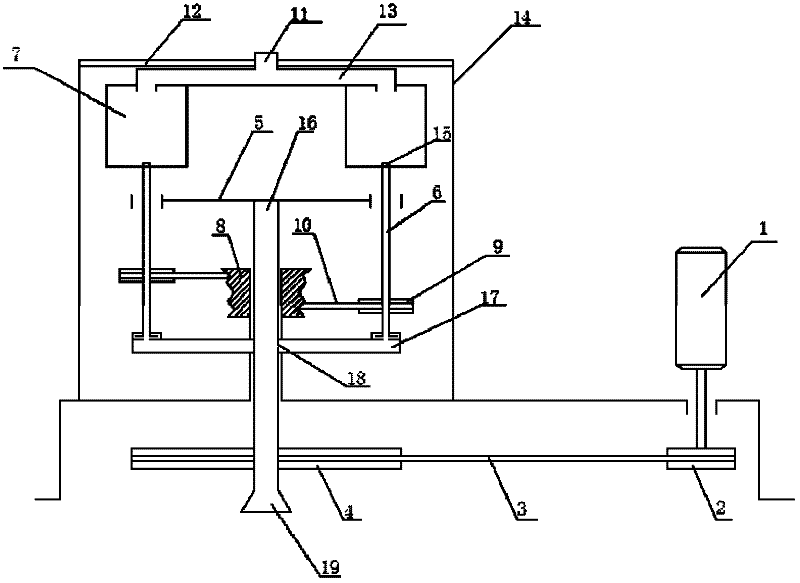

[0013] see figure 1 , the ball mill of the present invention includes a transmission mechanism and a rotary pair, wherein the small pulley 2 connected to the speed regulating motor 1 constitutes a first belt transmission mechanism through the first belt 3 and the large pulley 4, and is connected with the large pulley 4 through the central main shaft 16 and A plurality of ball milling jars 7 are symmetrically arranged on the coaxial rotating disk 5, and the rotating shaft 6 of each ball milling jar 7 forms a rotary pair with the rotating disk 5, and the lower part of the rotating shaft 6 is connected with a planetary pulley 9, and the planetary pulley 9 is in turn The center pulley 8 connected with the same base through the second belt 10 constitutes the second belt transmission mechanism, the central main shaft 16 and the rotating shaft 6 are hollow shafts, and the rotating shaft 6 is used to connect the ball mill pot 7 and the discharge device 17, and the ball mill pot The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com