Ground brush device of alternating current variable frequency motor

A grounding brush, AC frequency conversion technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of shaft current not hindering, burning out bearings, etc., to achieve the effect of simple structure and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

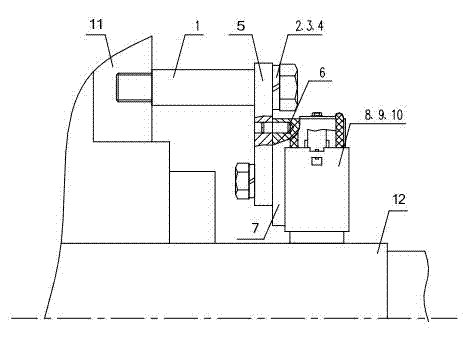

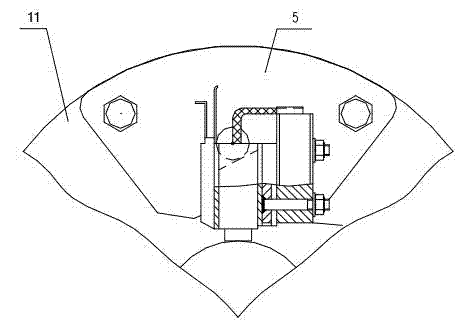

[0013] Such as figure 2 , image 3 As shown, the present invention includes a metal pipe 1, a galvanized steel hex bolt 2, a galvanized steel washer 3, a galvanized spring washer 4, a plate 5, a cylindrical pin 6, a connecting plate 7, a fixed brush box plate 8, an electric brush 9, Brush box 10 and insulating bearing sleeve 11. The brush 9 is installed in the brush box 10, the brush 9 and the brush box 10 are fixed by the fixed brush box plate 8 and then connected to the connection plate 7, the connection plate 7 is connected to the plate 5 through the cylindrical pin 6, the metal pipe 1 and the plate 5 and then connect to the insulating bearing sleeve 11 through the galvanized steel hex bolt 2, the galvanized steel washer 3, and the galvanized spring washer 4.

[0014] The installation process of the present invention is as follows: th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap