Multi-channel on-line sampling and sample introducing method for high-temperature high-thickness liquid material

A multi-channel directional valve and material liquid technology, applied in the direction of analysis of materials, instruments, etc., can solve the problems of long time period, high material consumption, complex and cumbersome process, etc., achieve real-time and reliability improvement, improve quality and output, The effect of reducing energy and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

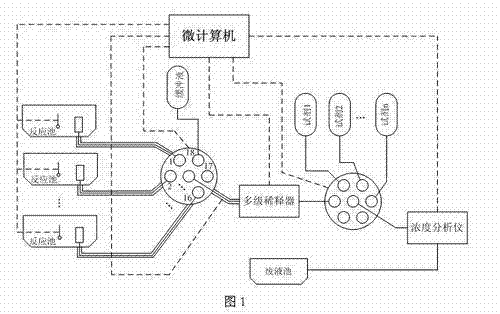

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

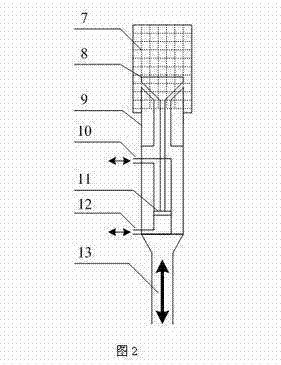

[0020] 1) Constant temperature sampling device

[0021] figure 2 It consists of a sampling valve, a gas circuit control unit, a constant temperature sampling pipeline, a shield and a filter screen 7. The device is installed vertically at the middle and lower parts of the reaction pools of each liquid to be tested, and the thermostatic sampling pipeline 13 is connected to the multi-channel directional valve 4 . The sampling valve is composed of a conical plug 8 and a sampling sleeve 9 , and the air circuit control unit is composed of an upper air hole 10 , a piston 11 and a lower air hole 12 . The filter screen 7 is fixed on the sampling sleeve, the thermostatic sampling pipeline is fastened to the lower end of the sampling sleeve 9 by fasteners, and the piston is connected to the tapered plug through a connecting rod. The gas circuit control unit is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com