Parallel precise measuring system for measuring surface area and perimeter of tiny object

A surface area and tiny technology, which is applied in the field of parallel precision measurement systems for the surface area and perimeter of tiny objects, can solve the problem of inability to quickly and accurately measure the surface area/perimeter of tiny objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

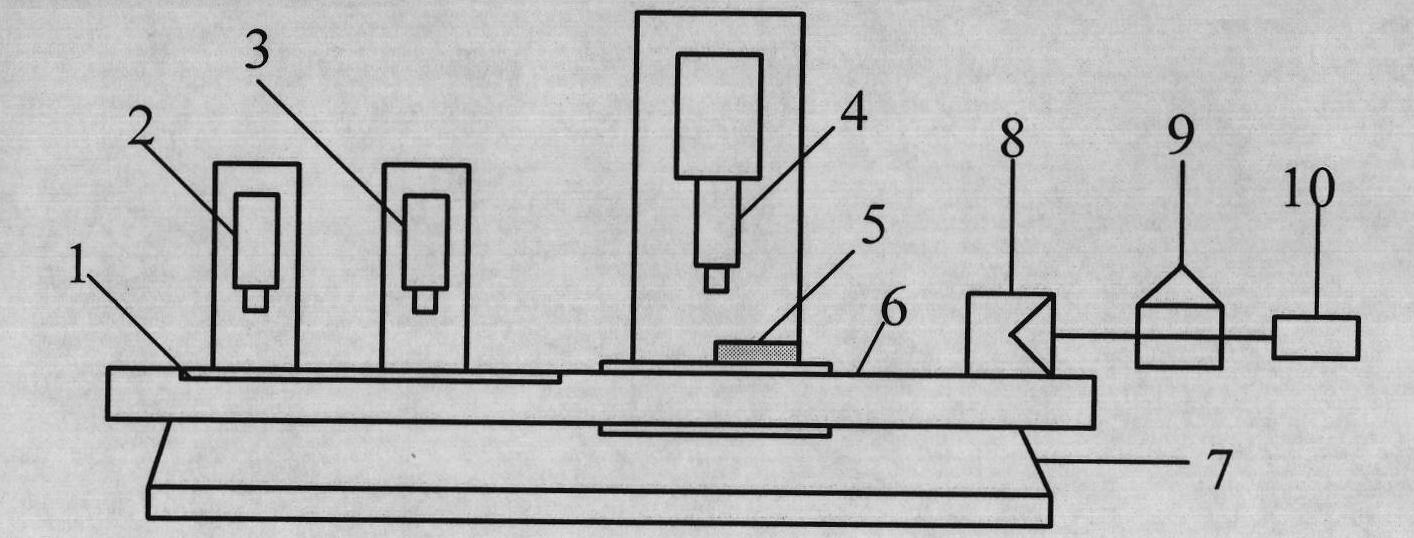

[0010] 5.1 Two-dimensional image measuring machine

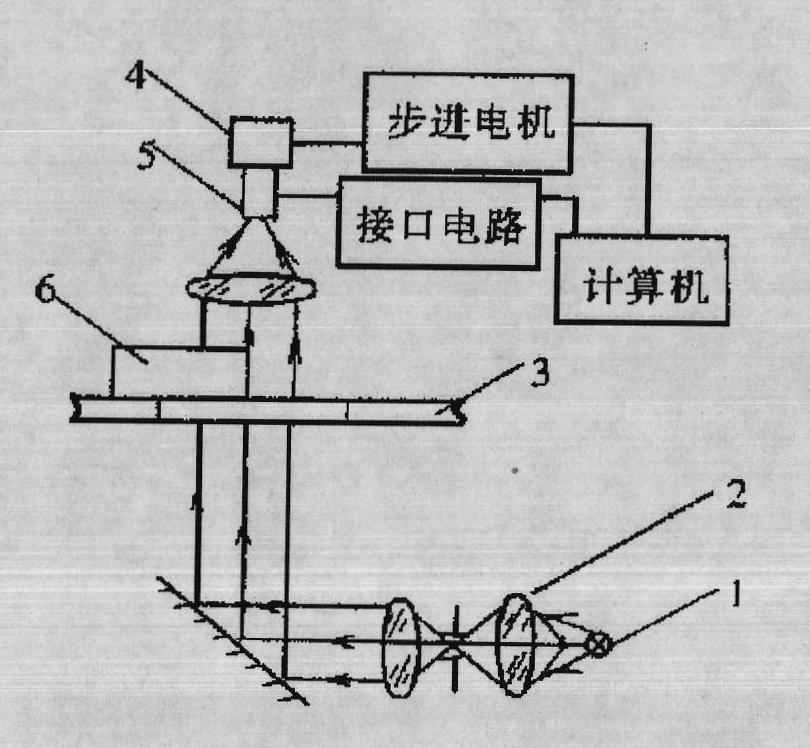

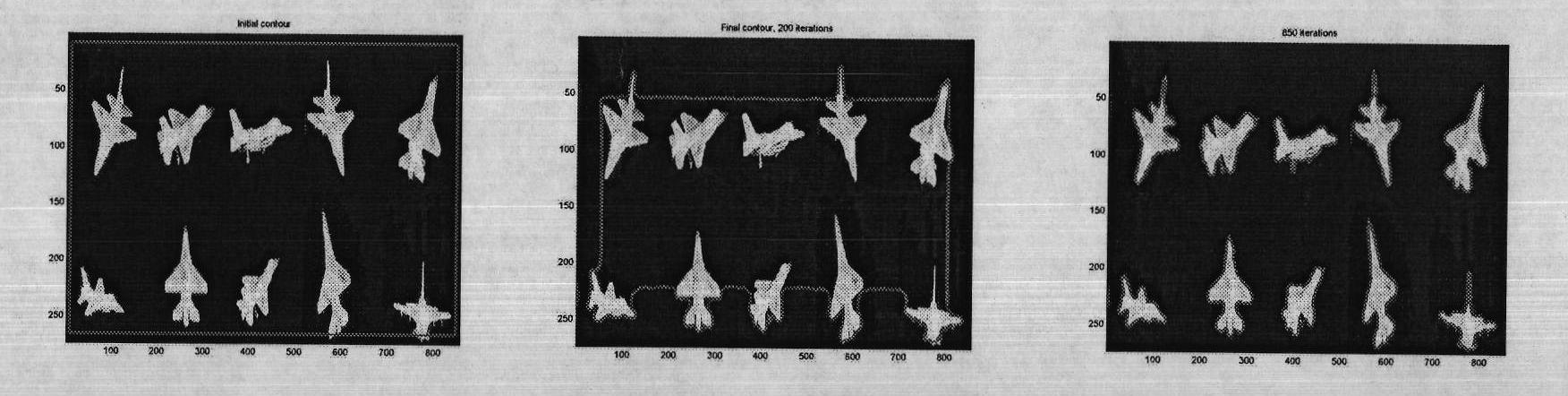

[0011] The two-dimensional image measuring machine is mainly composed of image-based displacement measurement system, image-based automatic focusing and aiming system and corresponding mechanical structure. The basic structure is as follows: figure 1 shown. Its basic working principle is: use two CCD cameras to pick up the position information of the vertical and horizontal optical scales respectively, and use the image card to connect with the computer, and determine the coordinate values of the two directions through image processing technology. The aiming system adopts a CCD camera to receive the outline of the object under test imaged by the optical system, which is also connected to the computer through the image card. In this way, on the one hand, the defocus information of the workpiece can be extracted through image processing technology, and the optical system and the camera can be driven up and down by using a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com