Method for improving quality of recyclable exhaust waste heat in power plant boiler and progressively utilizing exhaust waste heat

A technology for thermal power plants and boilers, which is applied in the field of step-by-step utilization and can solve the problems of boiler efficiency and low quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

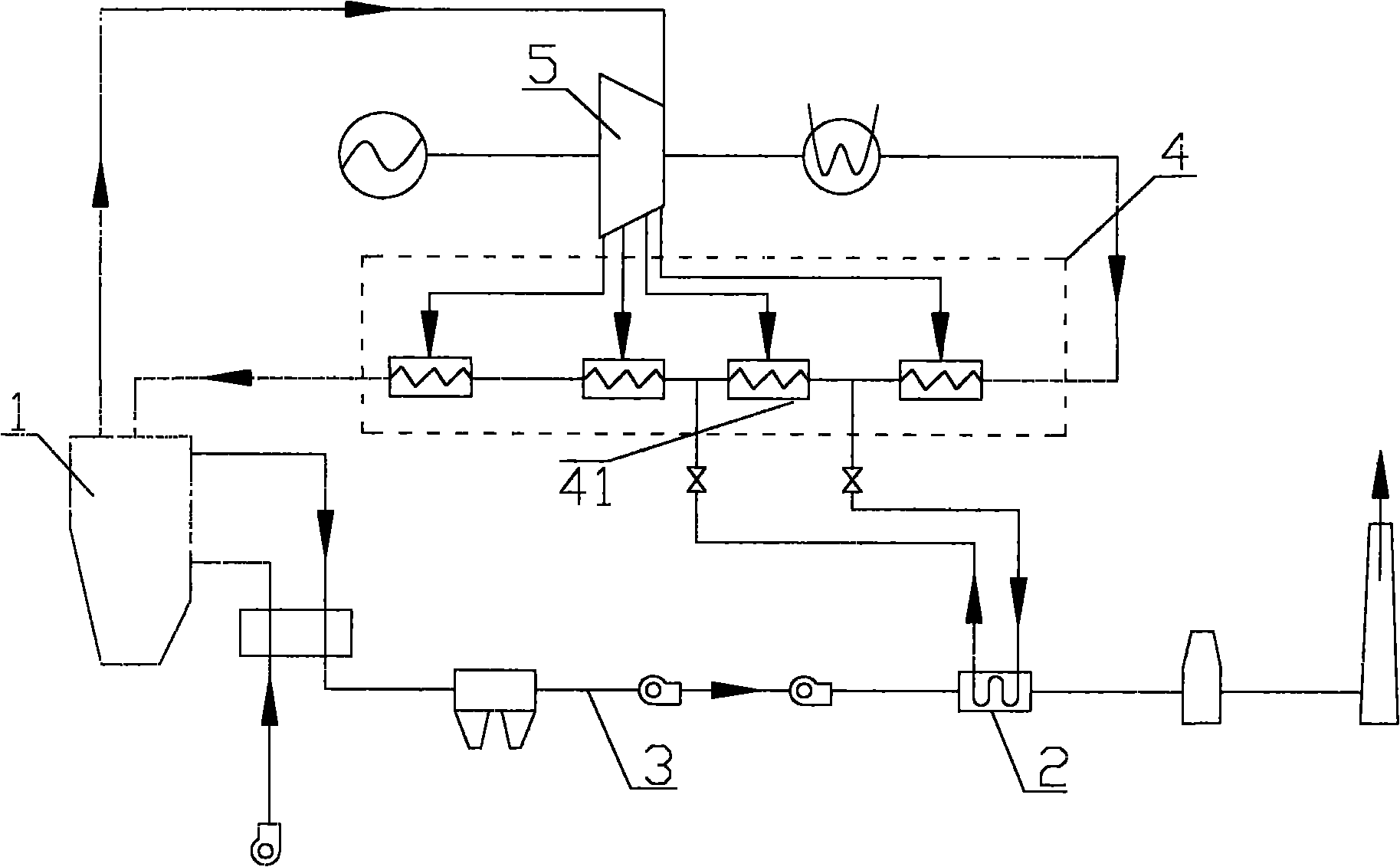

Image

Examples

Embodiment Construction

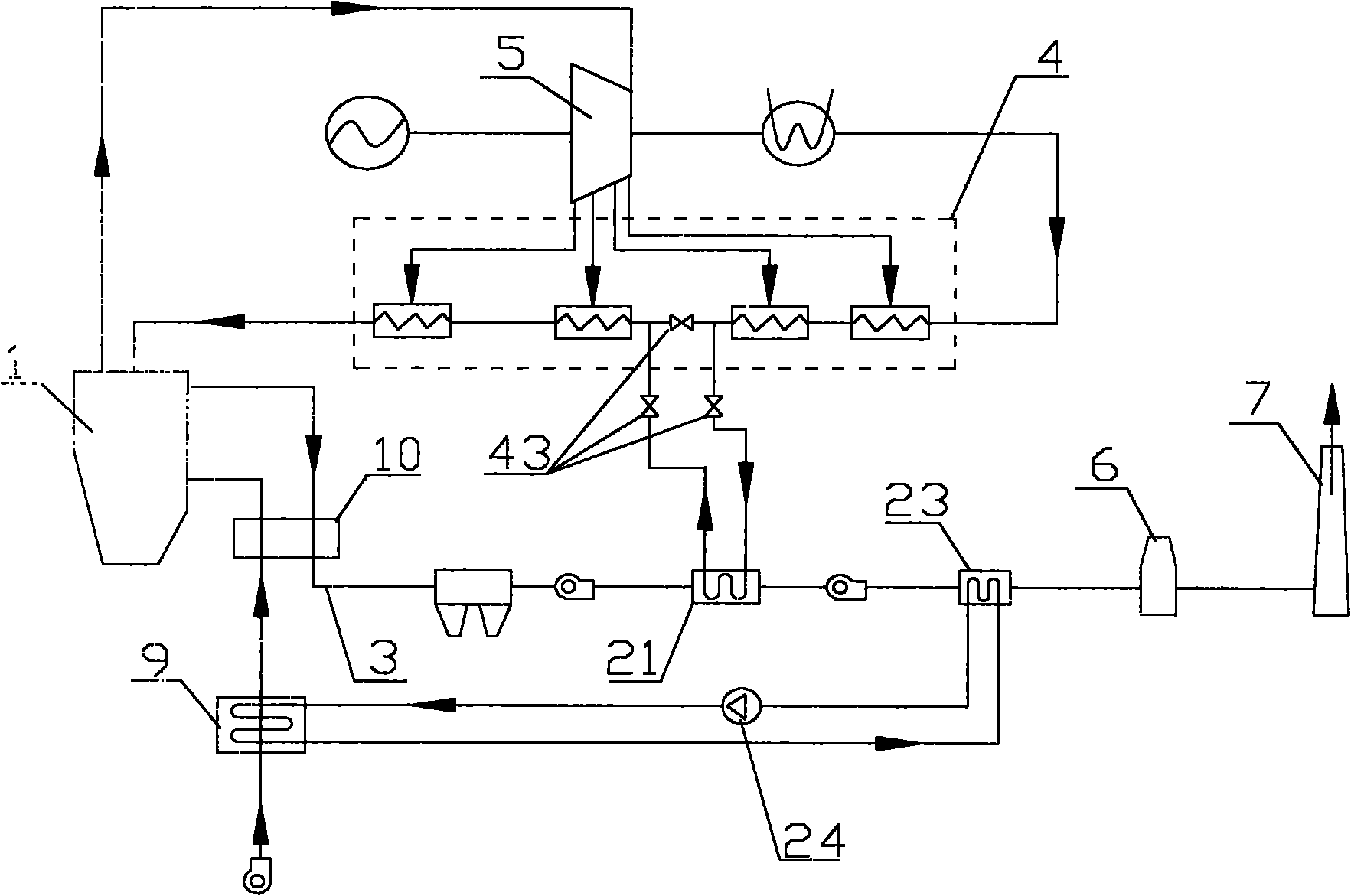

[0024] Such as image 3 As shown, the method of the present invention to improve the quality of recyclable exhaust smoke waste heat of boilers in thermal power plants and to utilize them step by step connects a heat source 9 in series at the front end of the air preheater 10 where the air of the boiler 1 is input into the cold air duct to heat the air entering the air preheater 10 , the first heat exchanger 21 is connected in series in the exhaust flue 3 of the boiler 1, the first heat exchanger 21 is arranged after the air preheater 10 of the exhaust flue 3 of the boiler and before the desulfurization tower 6 and is used for heating the boiler return Boiler feed water for thermal system 4.

[0025] The above-mentioned heat source 9 can be an air heater, and the second heat exchanger 23 is arranged before the desulfurization tower 6 of the boiler exhaust flue 3 and after the first heat exchanger 21, and the heat of the second heat exchanger 23 provides the air heater for The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com