Wall-penetrating device for stainless steel corrugated hose for gas delivery

A corrugated hose and stainless steel technology, applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of difficult operation, sinking into the wall, uneven wall, etc., and achieve the reduction of strength requirements and installation Requirements, reduce construction difficulty, adjust the effect of the angle at will

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

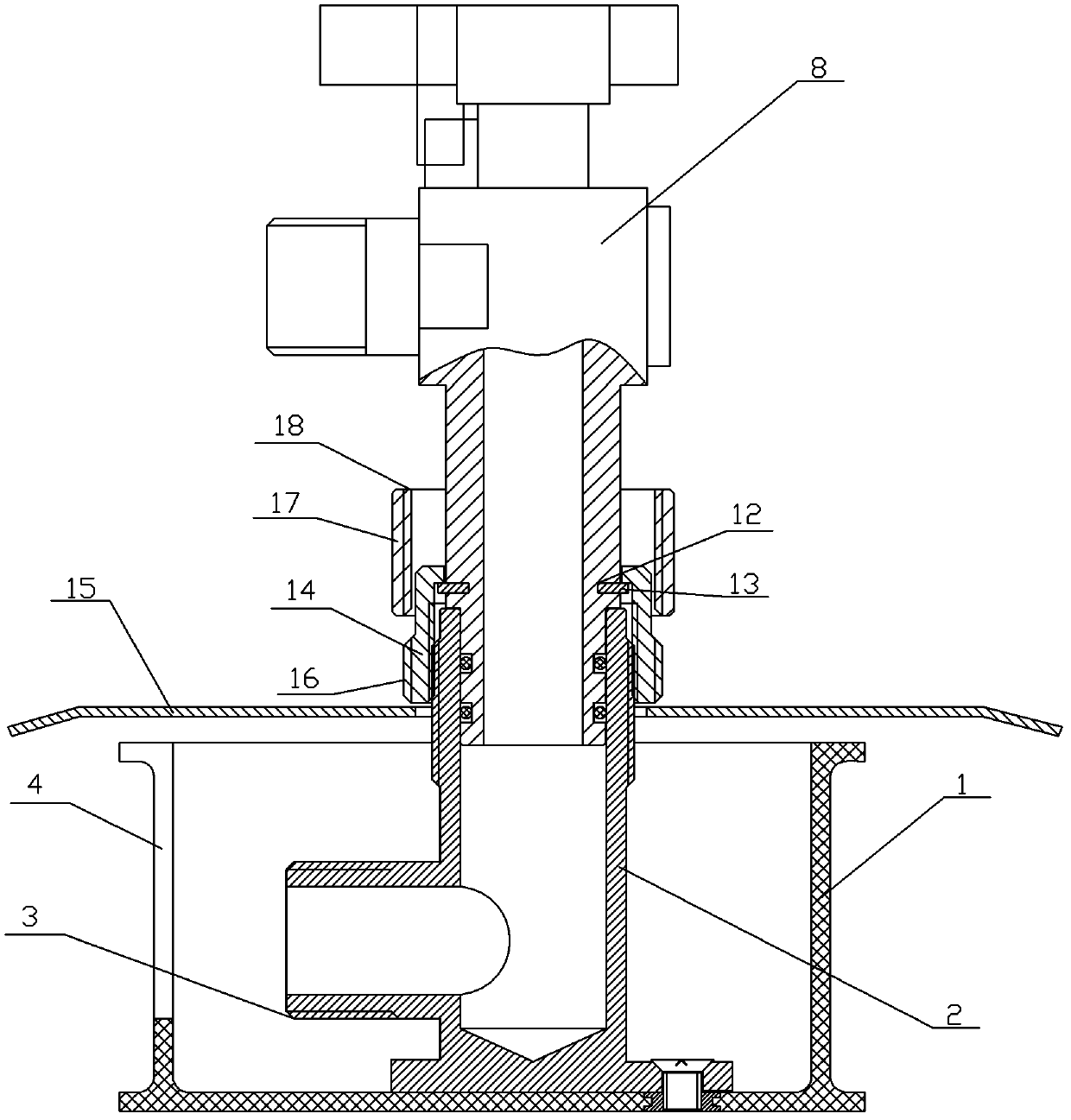

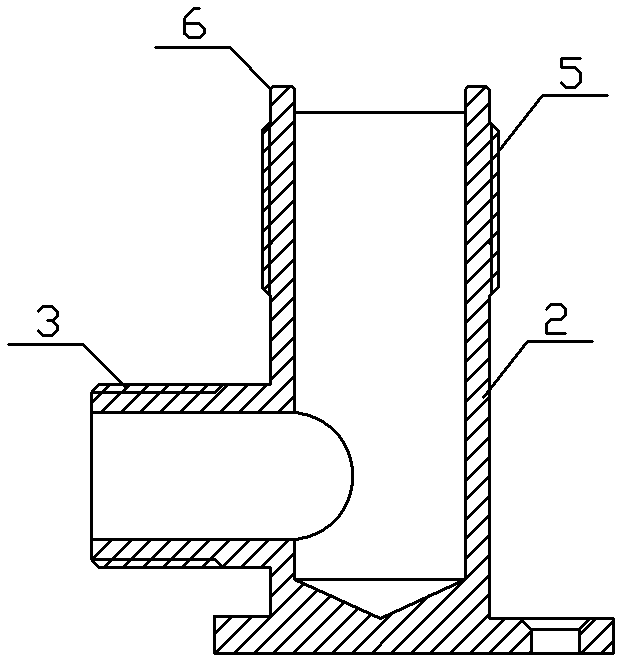

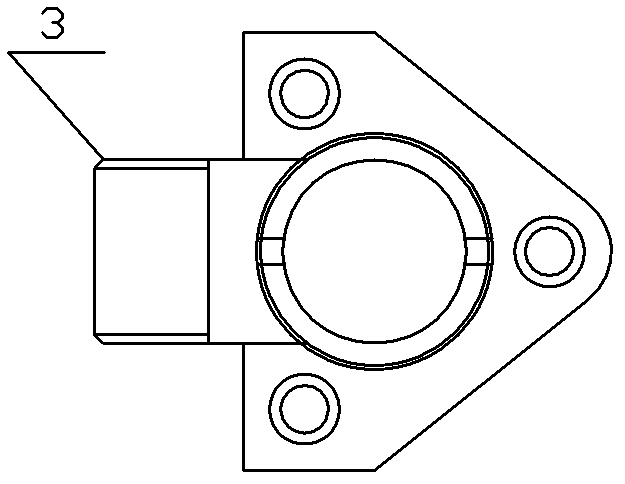

[0020] As shown in the figure, there is a stainless steel corrugated hose outlet device for gas transmission. There is a gap 4 on one side of the cassette seat 1. A 90-degree base elbow 2 is fixed on the bottom surface of the cassette base 1. The side end of the base elbow 2 is a The threaded interface 3, the outer end of the base elbow 2 is equipped with a matching gas angle valve 8, the lower part of the gas angle valve 8 forms a piston rod 10, and the lower part of the piston rod is placed in the base elbow.

[0021] The outer end of the base elbow 2 is provided with an external thread 5, and two symmetrical bosses 6 are provided on the port. The piston rod 10 is provided with four opening grooves 9 evenly distributed on the circumference. According to different directions, two of the opening grooves are selected to be embedded in the two bosses 6, and the wedge type is realized through the cooperation of the bosses and the opening grooves. position. The bottom of the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com