Method for preparing lysine

A lysine and lysine fermentation technology, applied in the field of lysine preparation, can solve the problems of low conversion rate, low acid supply in a single tank, and uncontinuous production, so as to achieve an increase in conversion rate and acid supply in a single tank The effect of increasing the quantity and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention provides a method for preparing lysine, which comprises the steps of inserting lysine fermentation strains into lysine fermentation culture liquid, and carrying out fermentation culture under the conditions of feeding carbon source and nitrogen source The lysine fermenting strain contains strains fermented and cultured for 8-30 hours under the lysine fermentation culture condition.

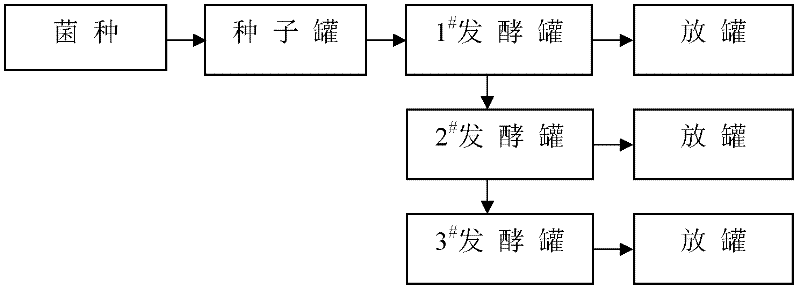

[0014] According to the present invention, the purpose of the present invention can be achieved by inserting the strains containing 8-30 hours of fermentation culture under lysine fermentation culture conditions into the culture liquid for fermentation culture, namely improving conversion rate and single tank acid supply amount, and the production can be carried out continuously, but in order to facilitate the collection of strains and make full use of the strains cultured by fermentation, preferably, the culture solution is loaded in one or more groups of fermentors, each grou...

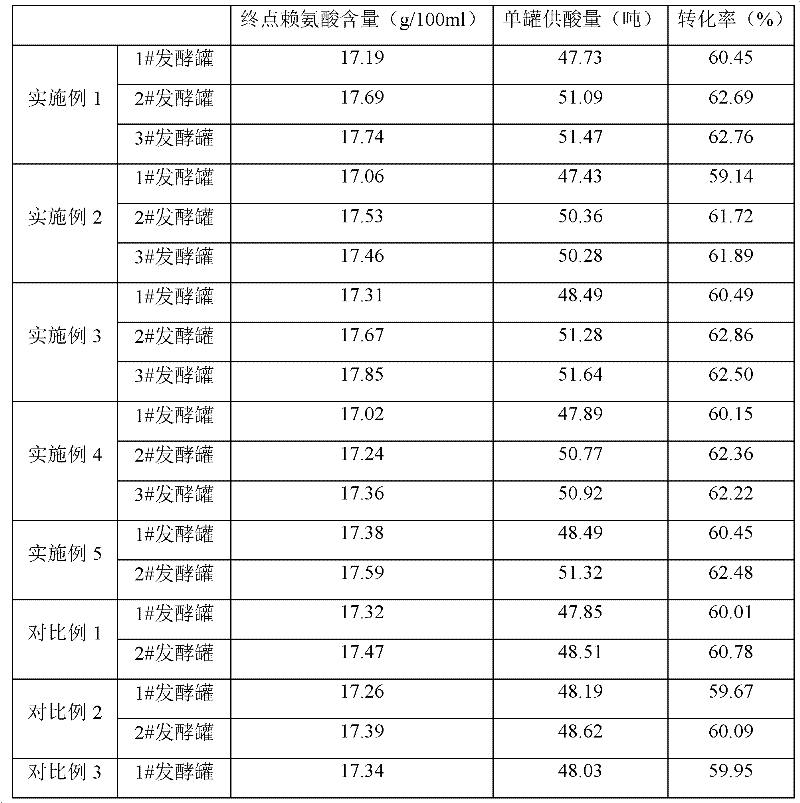

Embodiment 1

[0059] This example is used to illustrate the preparation method of lysine provided by the present invention.

[0060] (1) Machining 100 parts by weight of harvested corn to pulverize corn grains, so that the passing rate of corn flour through a 30-mesh sieve is 80%.

[0061](2) Add water to the pulverized product to 12Bé°, add 20 enzyme activity units of amylase (Novozymes, α-amylase) relative to the dry weight of each gram of the pulverized product, at 90°C, Enzymolysis was carried out for 100 minutes under the condition of pH 5.5 to obtain an enzymolysis product. Wherein, the enzymolysis product is filtered by a hydraulic plate and frame filter press, and the enzymolysis clear liquid (solid content is 20% by weight) is separated; 115 enzyme activity units of glucoamylase (α-1, 4 -glucose hydrolase, Novozymes), enzymolysis at 60° C. and pH 4.5 for 420 minutes to obtain saccharified supernatant liquid of starchy raw materials.

[0062] (3) use the starchy raw material sacch...

Embodiment 2

[0068] This example is used to illustrate the preparation method of lysine provided by the present invention.

[0069] The preparation method of the starchy raw material saccharification liquid, the formula of the seed tank culture medium, and the formula of the fermenter culture liquid are all the same as in Example 1.

[0070] Insert the activated and proliferated Brevibacterium flavum strains (the original strain FB42 was purchased from Jiangnan University) into the seed tank for cultivation. During the cultivation process, samples were taken for microscopic examination every 120 minutes and the OD value was determined. When normal and the OD value reached 0.8, the culture was stopped.

[0071] The volume of the culture solution in the 1# fermenter is 40% of the volume of the 1# fermenter. The seed solution cultivated in the seed tank was inserted into the culture solution of the 1# fermenter for fermentation and cultivation. Taking the inoculated culture solution as a ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com