Producing process of lysine

A production process, lysine technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of increasing production costs, excessive sewage, economic pressure and burden, etc., to save sewage and The effect of energy consumption, simple production process and wide application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with accompanying drawing and specific embodiment:

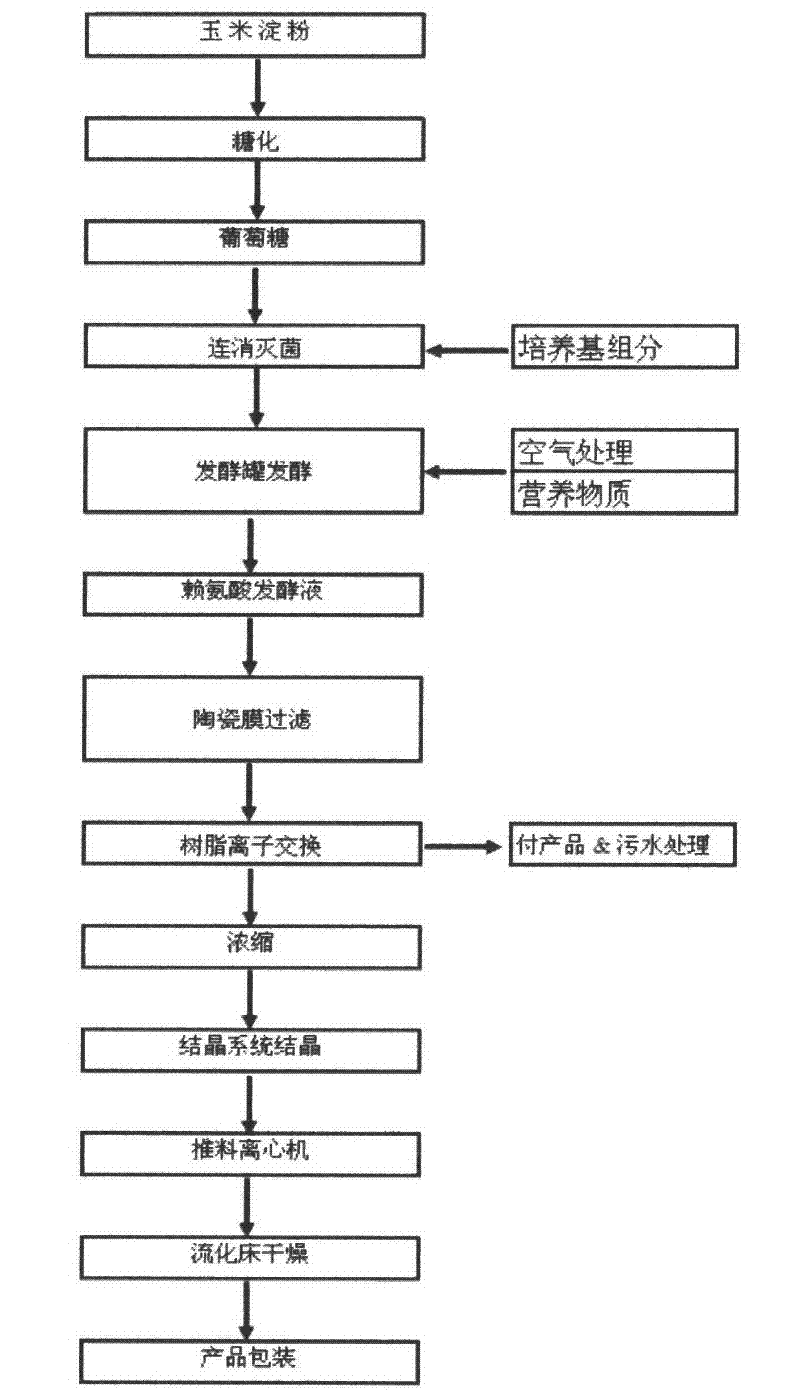

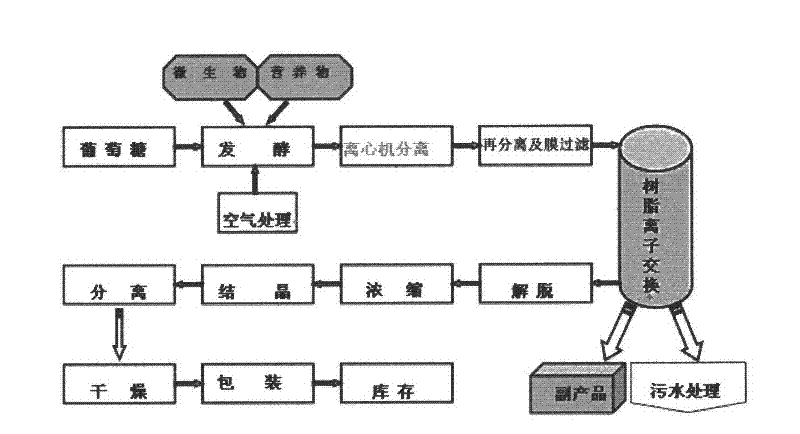

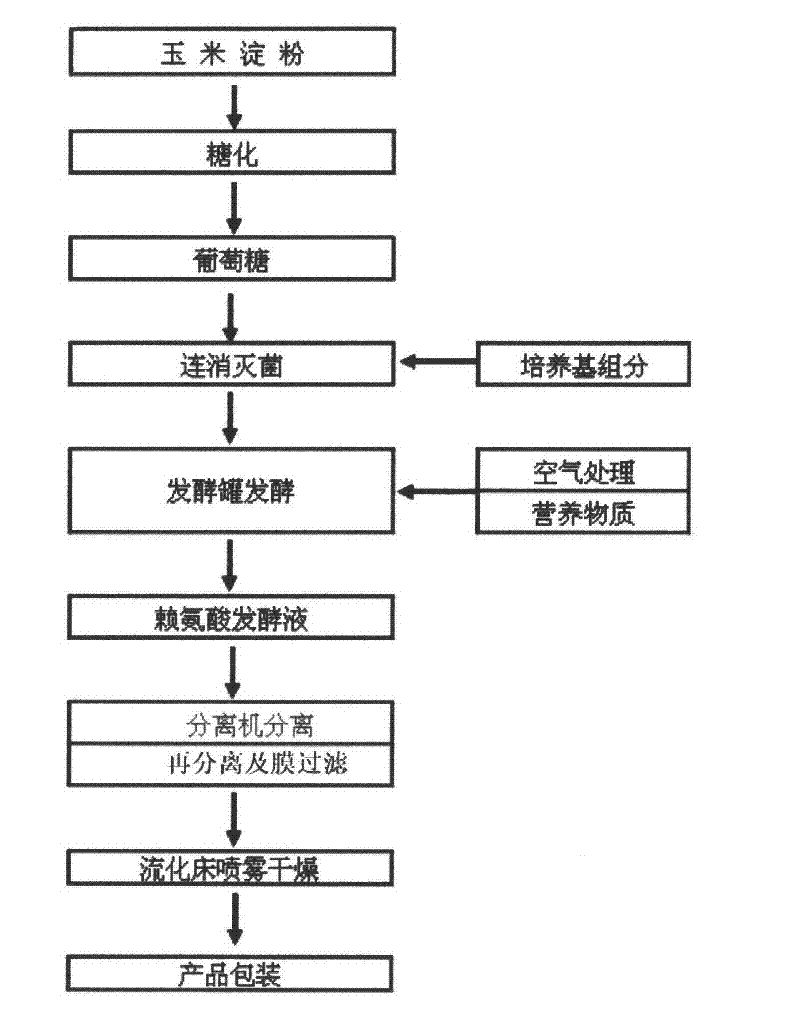

[0027] The production process of lysine mainly includes: saccharification, fermentation, separation, separation, concentration, crystallization, drying, product packaging and other links.

[0028] In the saccharification, cornstarch is added to amylase to hydrolyze the starch. The starch is first liquefied by the liquefying enzyme, and then saccharified to glucose by the glucoamylase.

[0029] For the above fermentation, the glucose, culture medium, and nutrients are continuously sterilized at a temperature of 126-130° C., maintained for 10-20 minutes, then cooled, and put into a fermenter according to a certain weight ratio for fermentation. , and fed into the air dissolved oxygen.

[0030] The separation and separation include: preliminary separation and re-separation, filtration and resin ion exchange, preliminary separation of the fermented lysine fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com