Propylene polymerization production technology by loop reactor batch liquid bulk method

A loop reactor, liquid phase bulk technology, applied in the field of olefin polymerization, can solve the problems of difficult to produce polypropylene products, single products, etc., and achieve the effects of improving utilization rate, uniform quality and high heat removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

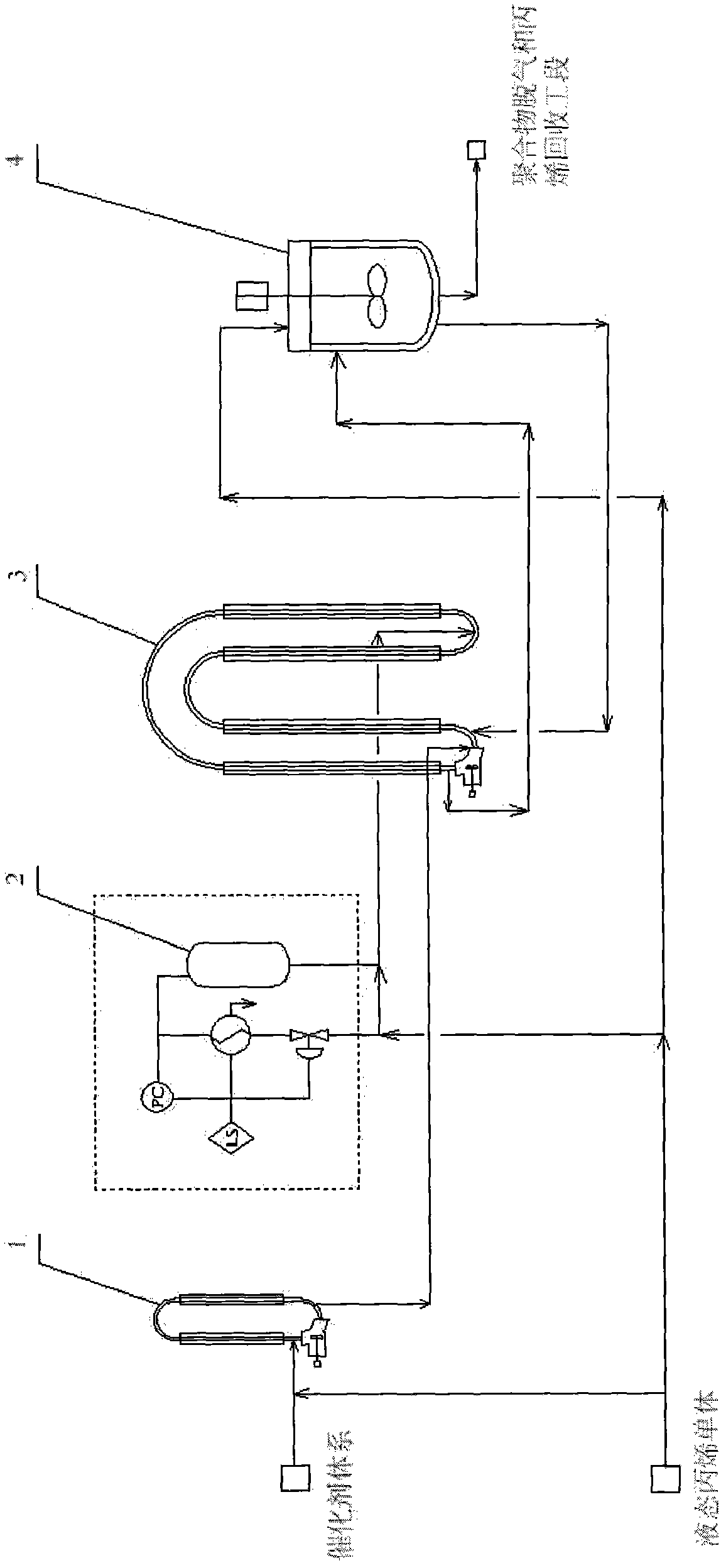

[0037] Taking the single-loop polypropylene plant with an annual output of 70,000 tons / year as an example, the attached figure 1 The improved technology of the scheme uses a liquid-phase bulk reactor with the same size as the reactor surge tank, the production capacity of the device can be increased by 20-50%, and the activity of the catalyst can also be increased by 20-50%. After modification, the device can produce polypropylene products with wide molecular weight distribution.

Embodiment 2

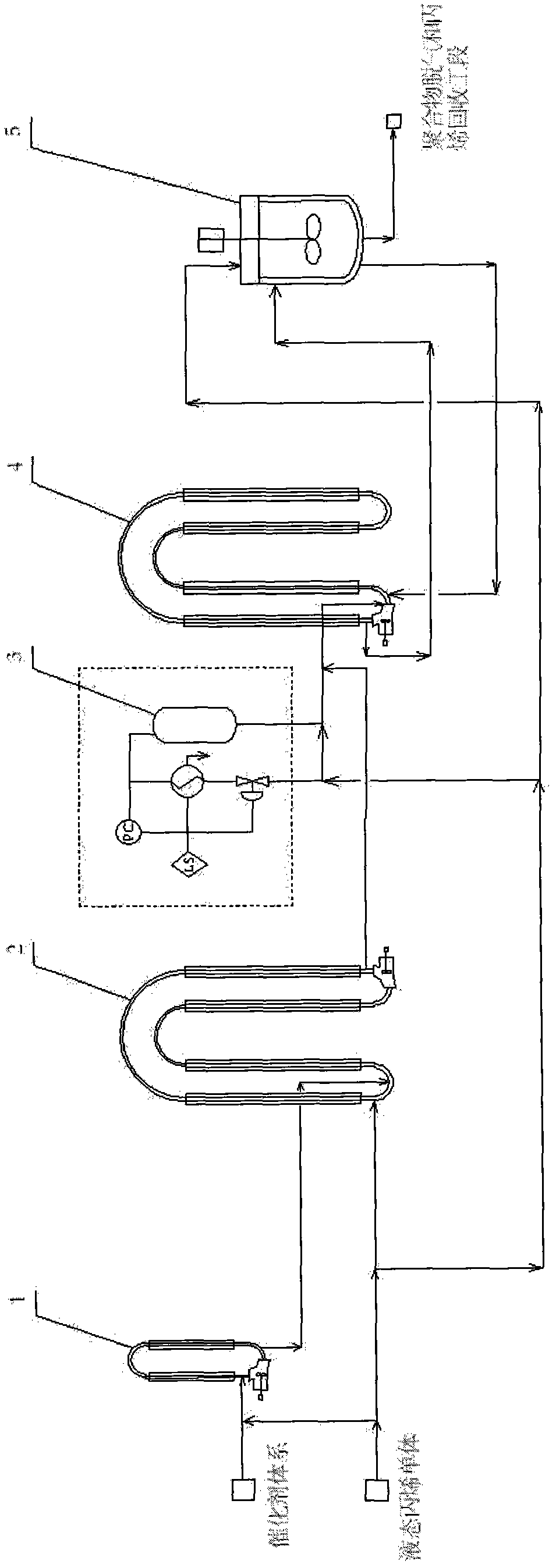

[0039] Taking the double-loop polypropylene plant with an annual output of 100,000 tons / year as an example, the attached figure 2 The improved technology of the scheme uses a liquid-phase bulk reactor with the same size as the reactor surge tank, the production capacity of the device can be increased by 20-30%, and the activity of the catalyst can also be increased by 20-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com