Loading and unloading system

A technology for articles and conveyors, which is applied in the field of speed improvement, and can solve problems such as inability to follow, reduction in supply and export speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the best embodiment for carrying out the present invention will be described. The scope of the present invention should be determined based on the description of the patent claims, with reference to the description in the specification and known technologies in the field, and based on the understanding of those skilled in the art. Various changes can be made within the scope not departing from the spirit of the invention. In particular, a plurality of embodiments and modifications described in this specification can be combined arbitrarily as necessary.

[0024] (Example)

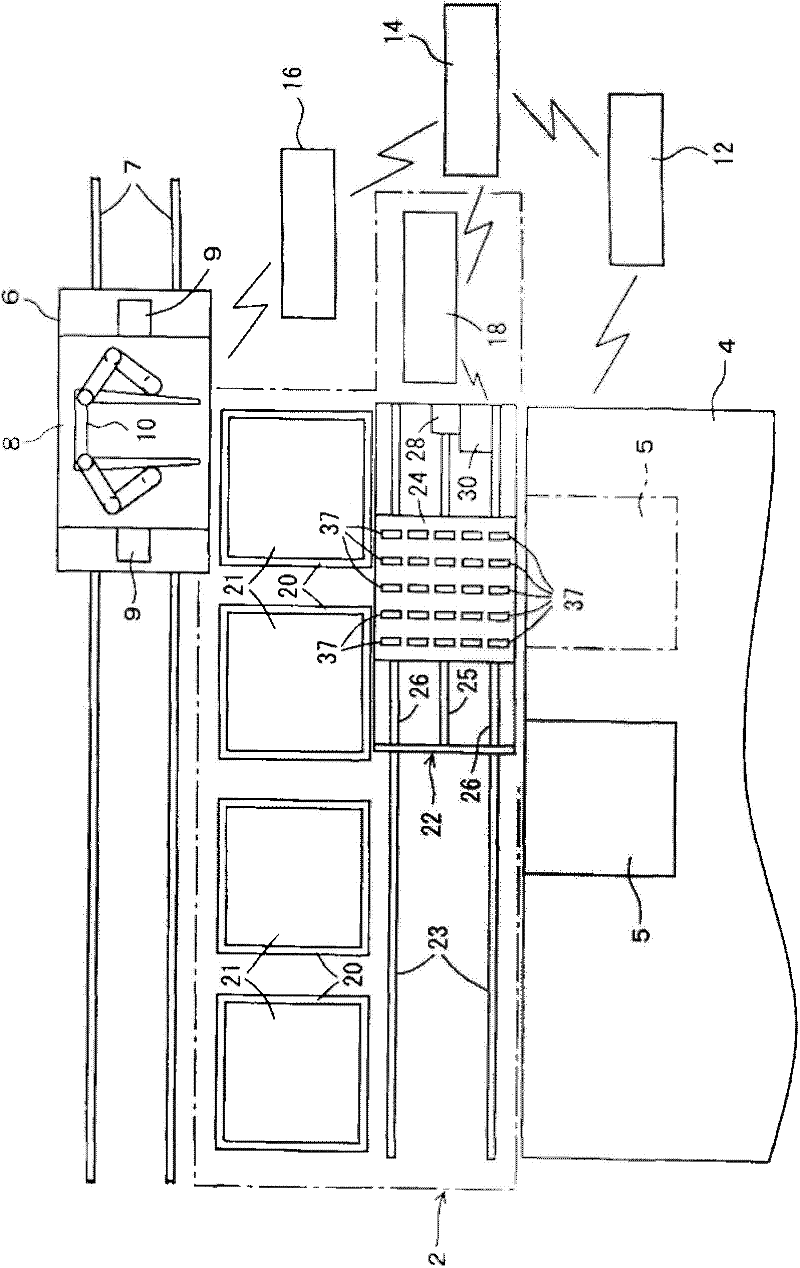

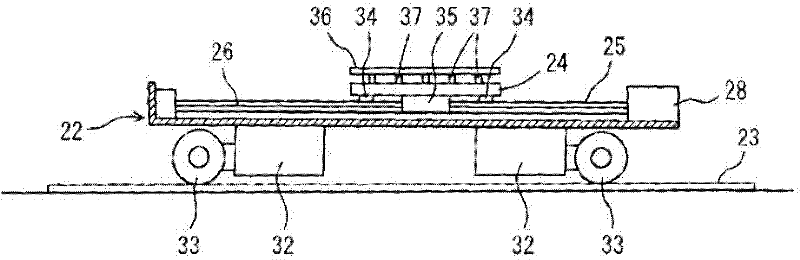

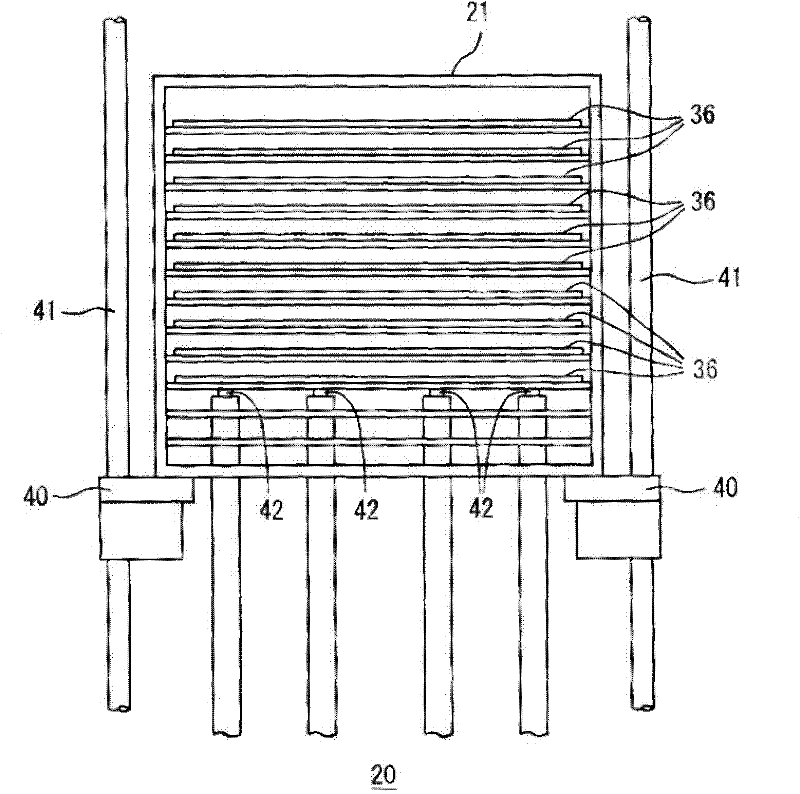

[0025] Figure 1 to Figure 7 Examples and modifications thereof are shown. In the figure, 2 is a supply and unloading system, between the station 5 of the processing apparatus 4 and the cassette station 20, supplies and unloads articles such as liquid crystal display substrates one article at a time. Furthermore, in addition to this, supply and discharge are also performed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com