Straw curing and molding machine

A technology of solidification molding and molding machines, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., which can solve the problems of inconvenient transportation of straw, and achieve the effects of saving energy costs, wide application range, and less ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

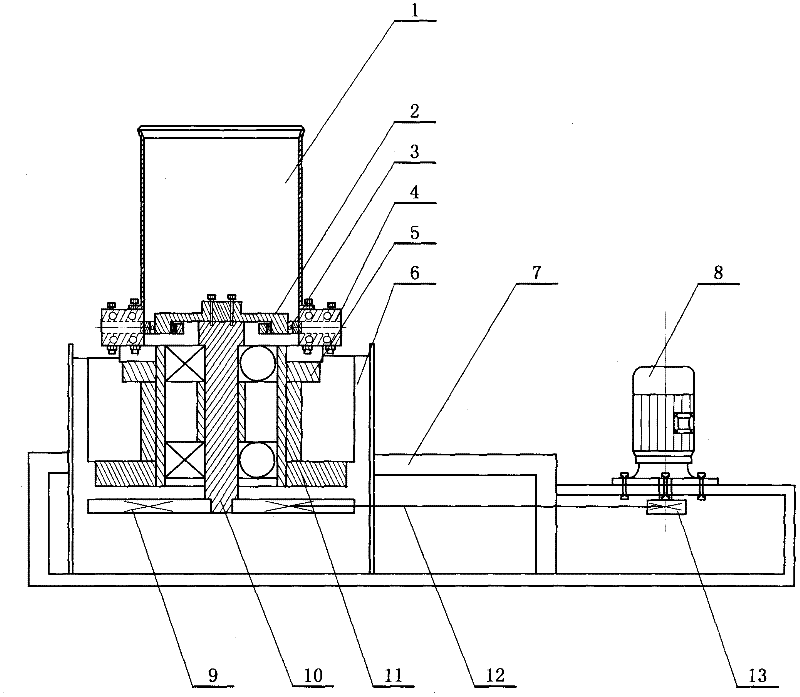

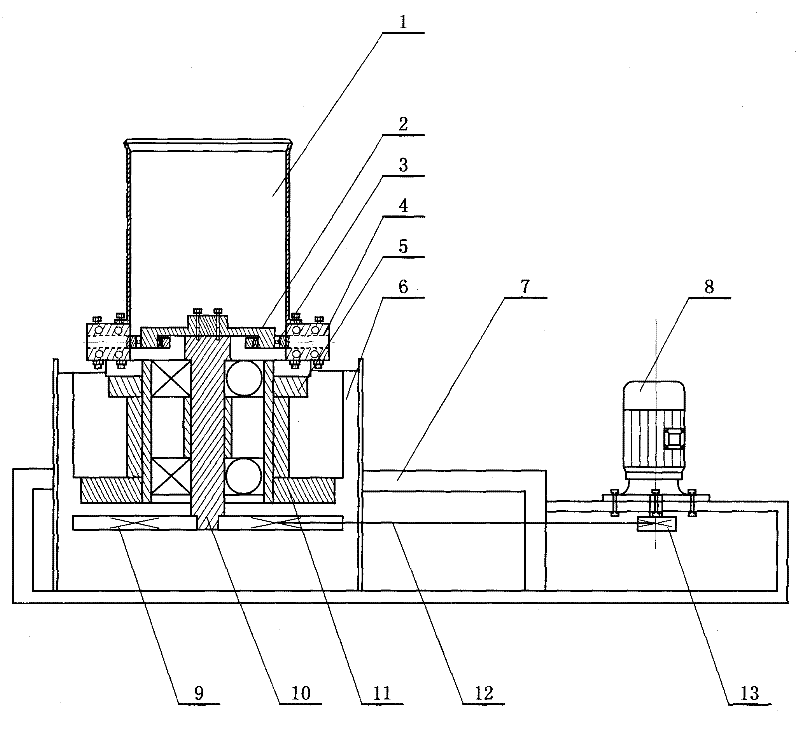

[0009] in figure 1 Among them, the straw curing forming machine mainly includes a feeding hopper 1, a lever 2, a curing forming mold plate 4, a base 5, a receiving plate 6, a frame 7, a belt 12, a motor 8, a small pulley 13, a large pulley 9, The central shaft 10, the pressing wheel 3 and the fastening chuck 11; below the hopper 1 is provided with a ring-shaped curing forming mold plate 4, which has an electric heating structure and a forming hole outside the circumference , Make the curing molding die plate 4 shape and solidify the straw under the heating state, and discharge the molded materials from the molding hole, and the solidification molding die plate 4 is fixed on the lower base 5 and the frame 7, and the frame 7 is set There is a receiving plate 6 and a central shaft 10 corresponding to the curing and forming mold plate 4. The upper end of the central shaft 10 is sequentially fixed with a lever 2 and a pressing wheel 3, and the pressing wheel 3 rotates corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com