Automatic plane polishing device

An automatic polishing and transmission technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of backward equipment, poor quality, low production efficiency, etc. High production efficiency and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

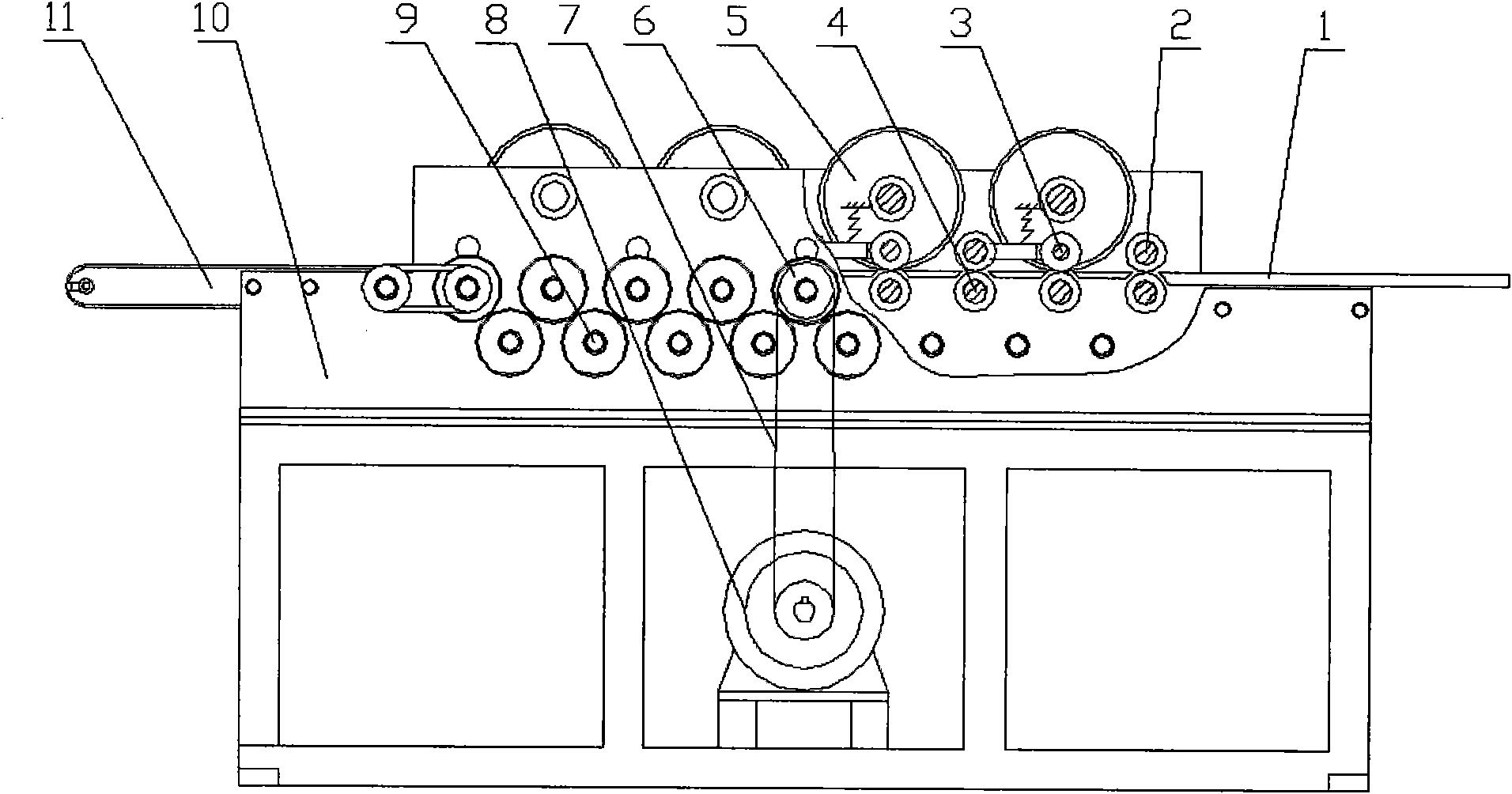

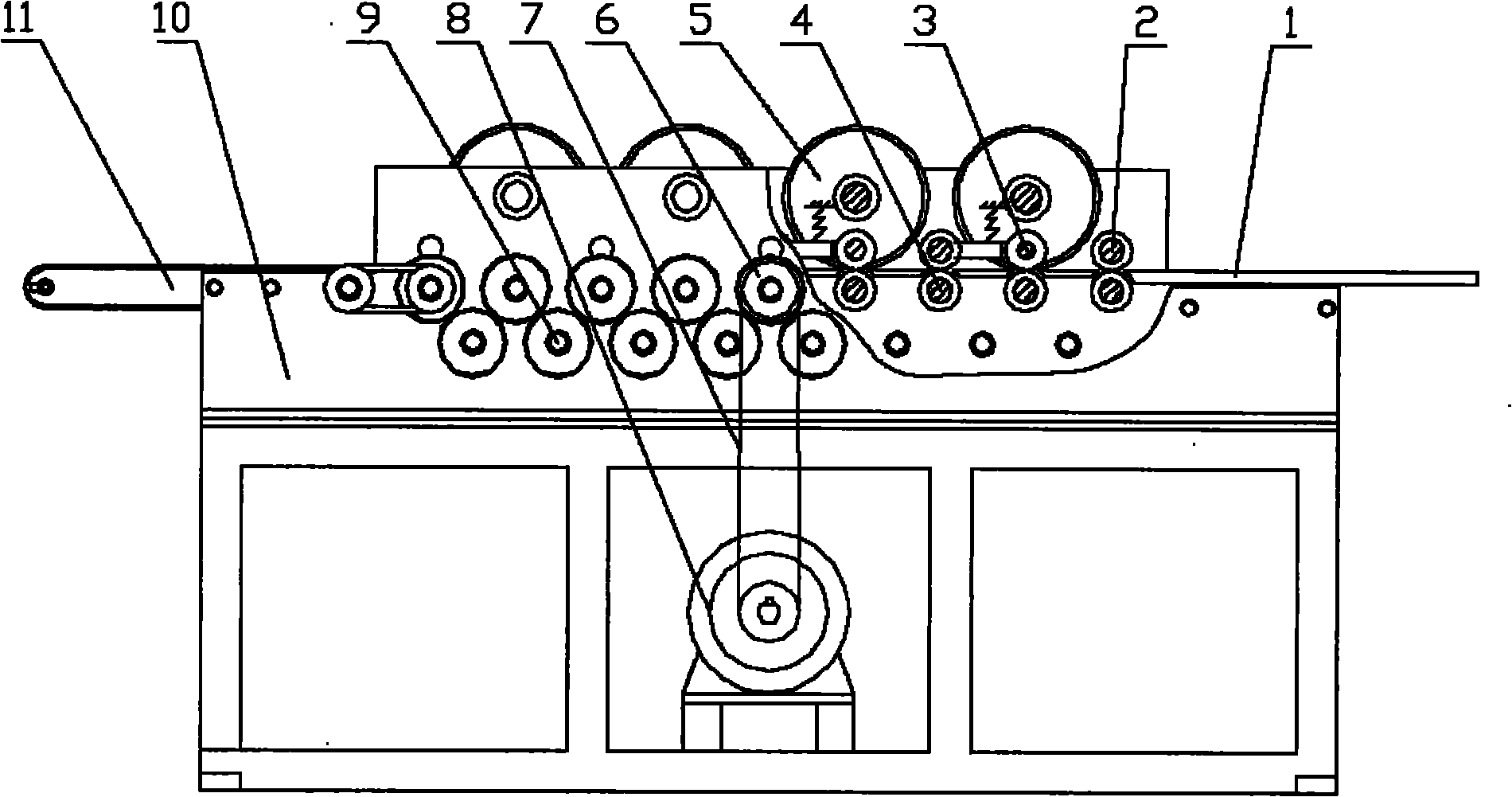

[0011] This embodiment provides a flat automatic polishing device, including a feeding table 1, a pressure roller 2, a point pressure roller 3, a driving roller 4, a polishing wheel 5, a sprocket 6, a transmission chain 7, a feed motor 8, a Gear 9, frame 10, blanking device 11, transmission device 12, polishing motor 13;

[0012] Among them: the feeding table 1 is installed on the frame 10, the feed motor 8 is installed on the frame 10, the pressure roller 2 and the driving roller 4 are pressed and installed on the frame 10, and the feed motor 8 passes through the transmission chain 7 and sprocket wheel 6 are connected with driving roller 4, and driving roller 4 is connected with reversing gear 9 through gear, and polishing wheel 5 is connected with polishing motor 13 through transmission device 12, and unloading device 11 is installed on the loading table 1. The point pressure roller 3 is hingedly mounted on the shaft of the polishing wheel 5 through a connecting rod, and the...

Embodiment 2

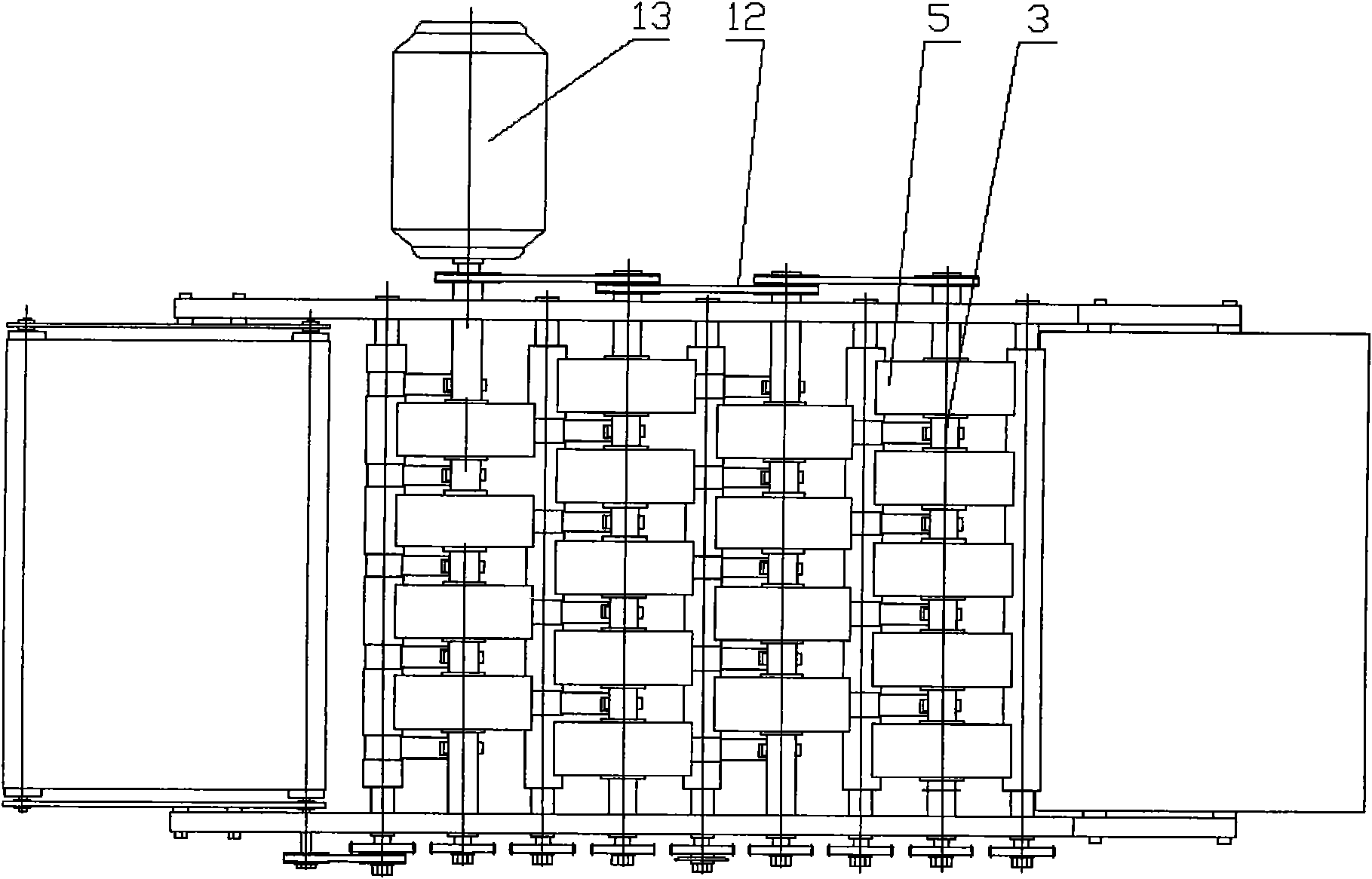

[0016] This embodiment provides a flat automatic polishing device, including a feeding table 1, a pressure roller 2, a point pressure roller 3, a driving roller 4, a polishing wheel 5, a sprocket 6, a transmission chain 7, a feed motor 8, a Gear 9, frame 10, blanking device 11, transmission device 12, polishing motor 13;

[0017] Among them: the feeding table 1 is installed on the frame 10, the feed motor 8 is installed on the frame 10, the pressure roller 2 and the driving roller 4 are pressed and installed on the frame 10, and the feed motor 8 passes through the transmission chain 7 and sprocket wheel 6 are connected with driving roller 4, and driving roller 4 is connected with reversing gear 9 through gear, and polishing wheel 5 is connected with polishing motor 13 through transmission device 12, and unloading device 11 is installed on the loading platform 1. The point pressure roller 3 is hingedly mounted on the shaft of the polishing wheel 5 through a connecting rod, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com