Equipment for grinding raw material strip working surface of leather machinery blade

A technology of mechanical blades and working surfaces, which is applied in the field of equipment for grinding the working surface of leather mechanical blade raw materials, can solve the problems of easy damage to the tool, poor cutting performance, and the hardness of the working surface of the blade cannot meet the standard, and achieve Improve grinding performance, reduce working temperature and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings.

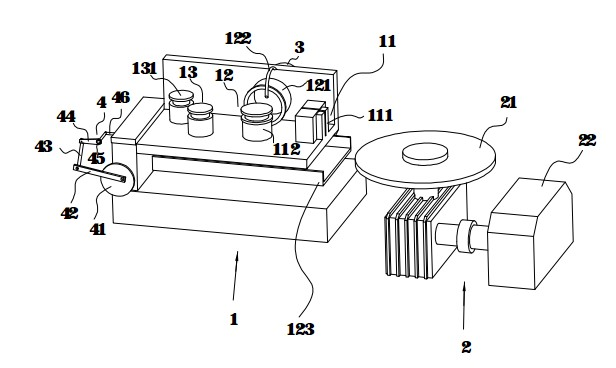

[0021] Such as figure 1 As shown, a leather machine blade raw material strip working surface grinding equipment includes a workbench 1 and a feeding mechanism 2, and the workbench 1 includes a feeding guide section 11, a grinding section 12 and a discharge section 13, and the grinding section 12 Grinding wheel 121 is installed, and the grinding wheel 121 is connected to the main shaft 3. The grinding wheel 121 is a hollow barrel-shaped grinding wheel. The main shaft 3 is driven by power. One side of the workbench 1 is also provided with a feed compensation device 4 for adjusting the axial feed of the grinding wheel 121. The feed compensation device 4 includes a large wheel 41 driven by power, the large wheel 41 is eccentrically hinged to the crank 42, the crank 42 is hinged to one end of the connecting rod 43, and the other end of the connecting rod 43 is hinged to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com