Thread machining technology equipment for a connecting rod of a press machine

A thread processing and press technology, applied in metal processing equipment, metal processing machinery parts, thread cutting machines, etc., can solve the problems of quality decline, product scrapping, low efficiency, etc., achieve high work efficiency, reduce the number of corrections, overcome Effects of Baseline Changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

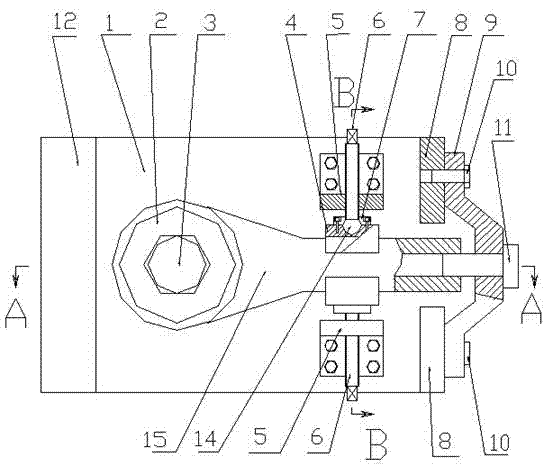

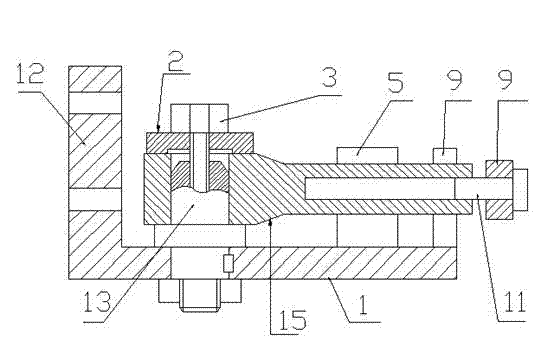

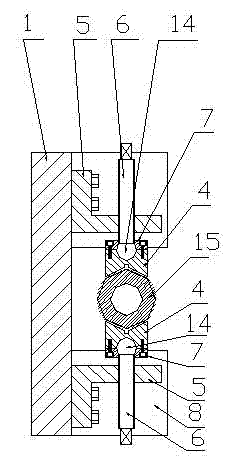

[0010] A fixed mandrel 13 is vertically installed on the support base plate 1, and an internally threaded hole is formed in the middle of the mandrel 13 upper ends, and a locking bolt 3 is housed in the internally threaded hole, and a pressing plate 2 is housed on the locking bolt 3. The head of the support base plate 1 is provided with a fixed plate 12, the fixed plate 12 is in a vertical state with the support base plate 1, and on both sides of the other end of the support base plate 1, a process table 8 is symmetrically arranged, and the described process table The left and right side surfaces of 8 are parallel to the left and right side surfaces of the fixed plate 12, the symmetrical axis of the two process tables 8 coincides with the center line of the mandrel 13, and the bridge frame 9 is connected with the two process tables 8 through two positioning pins 10, And can be easily separated, the middle part of the bridge frame 9 is equipped with a correction pin shaft 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com