Special door jig for coating

A special door and painting technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of affecting the coating quality, falling off of paint particles, easy to generate friction, etc., to avoid the falling of paint slag and installation. Trouble, prevent paint slag from being generated and fall off, prevent paint slag from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

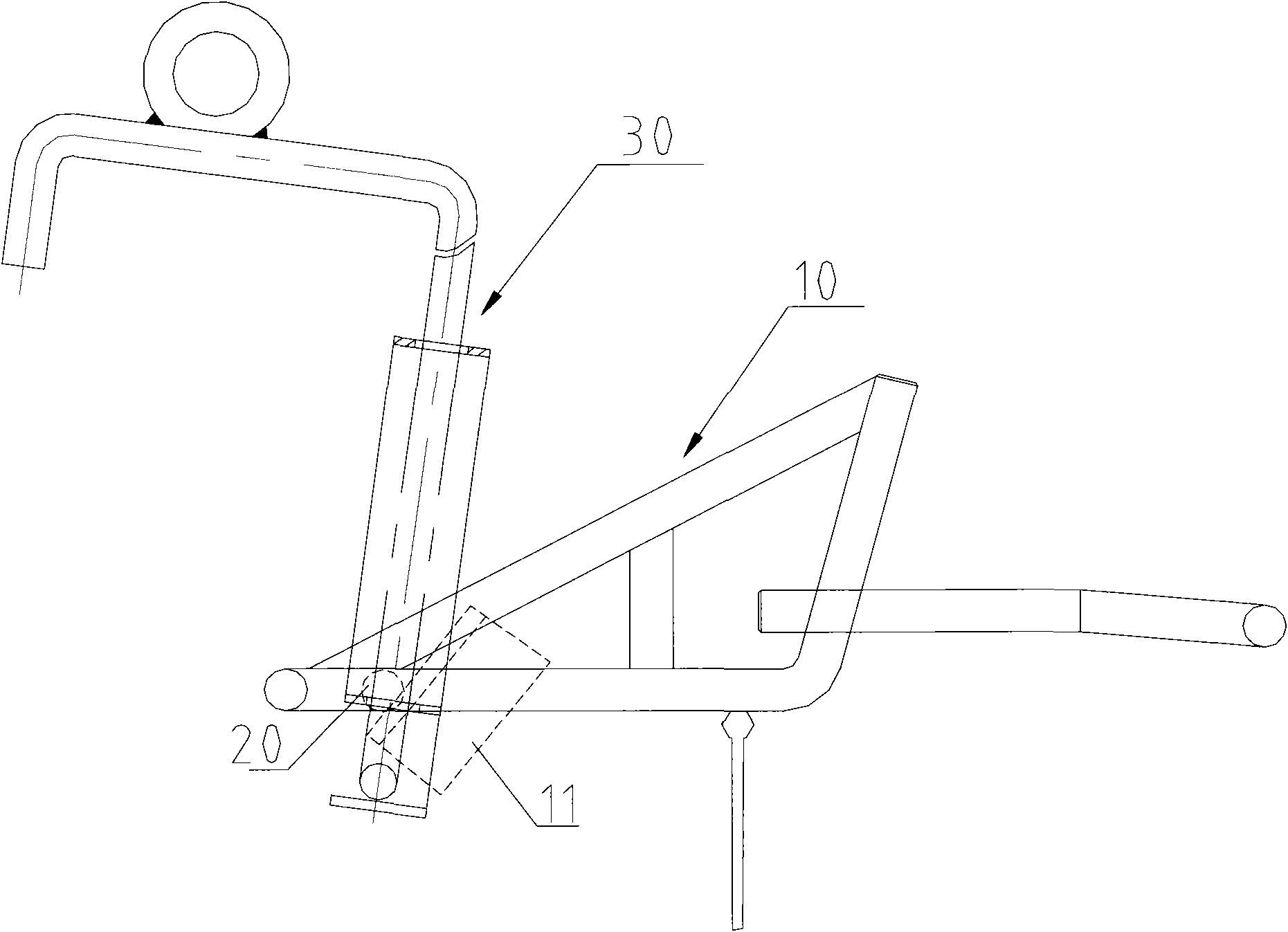

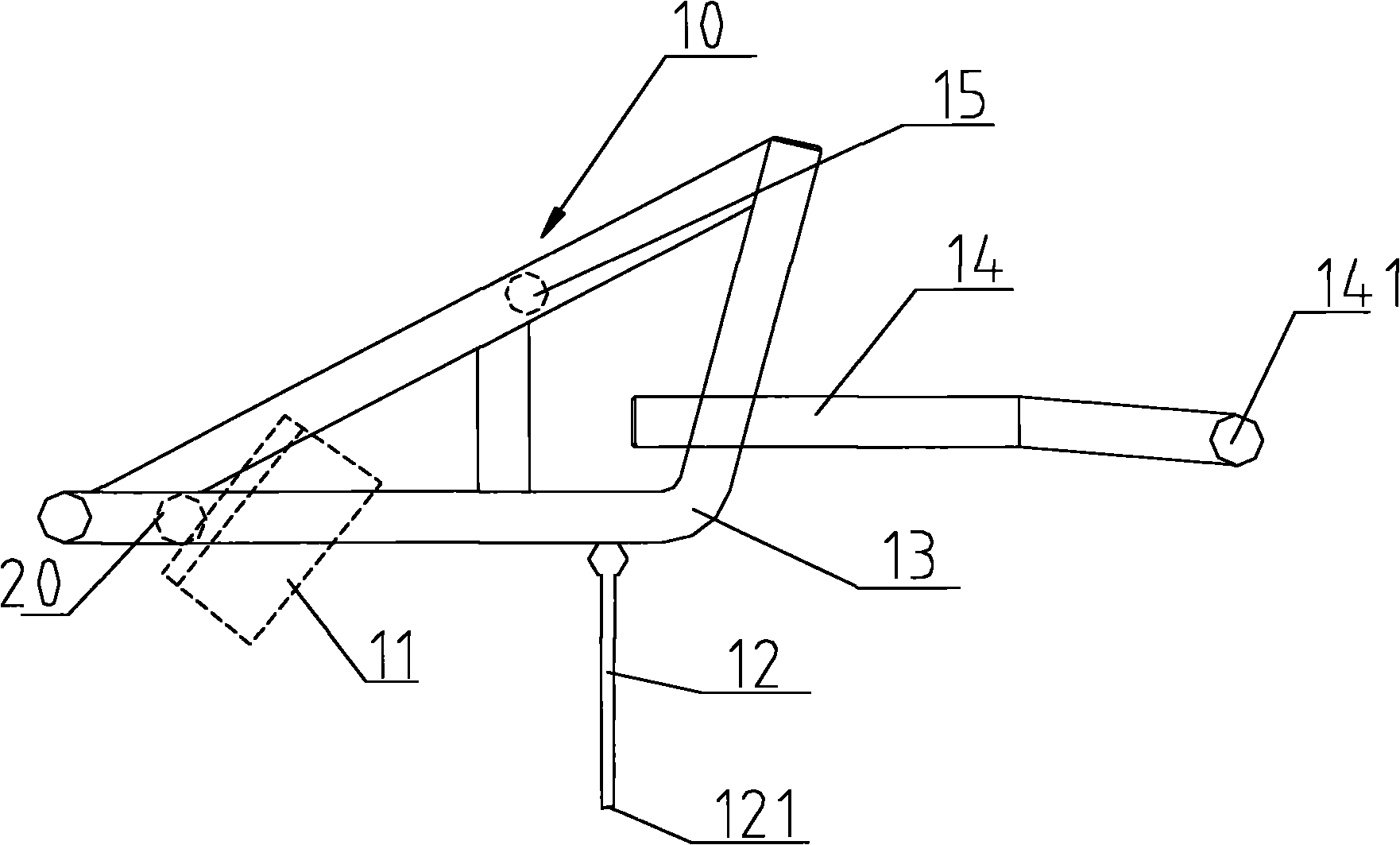

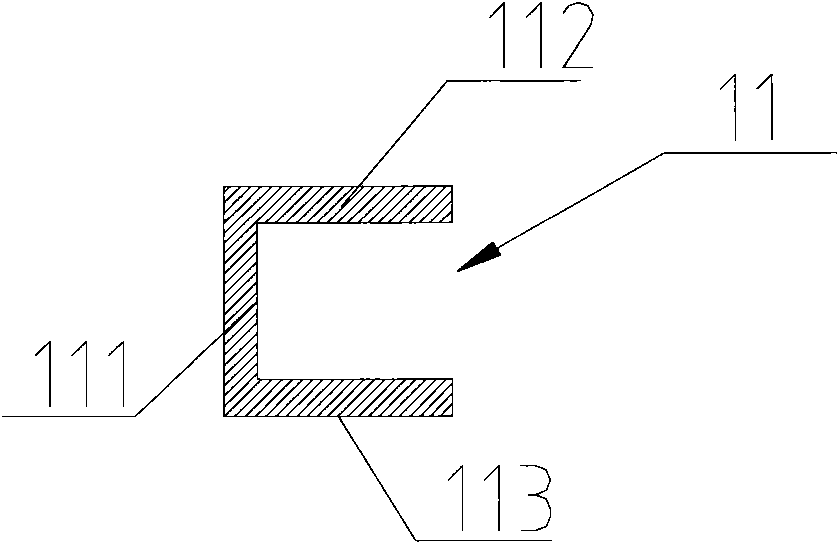

[0022] Figure 1-Figure 4 An embodiment of the painting-specific door fixture of the present invention is shown. As shown in the figure, the painting-specific door fixture includes a positioning device 10 , an isolation device 20 and a latching device 30 . figure 1 , 2 , 4 shows the view from the inside of the vehicle when the special door fixture for painting is in the installation position. Wherein, the positioning device 10 includes a positioning support frame 13. In this embodiment, the positioning support frame 13 is triangular in shape. Of course, in other embodiments of the present invention, the positioning support frame can also be in other shapes, as long as the structure is stable.

[0023] Such as figure 1 , figure 2 As shown, on the positioning surface of the positioning support frame 13 (ie figure 1 Verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com