Dual-channel condenser with heat recovery and condensing temperature control structure

A technology to control the structure and condensation temperature, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of low operating efficiency, affecting efficiency, and many equipment components, and achieve the effect of high operating efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

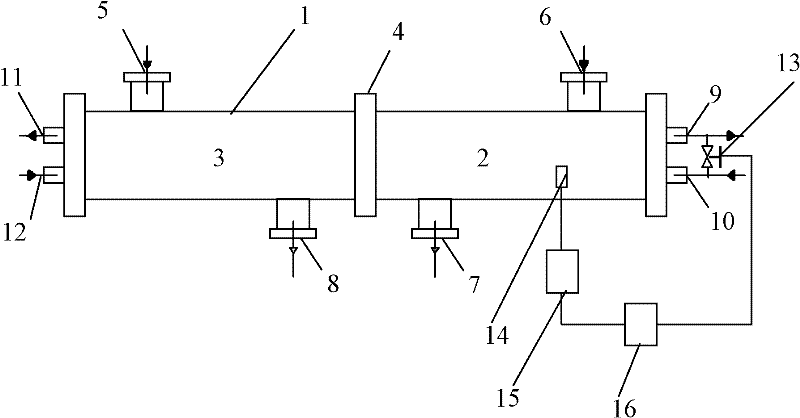

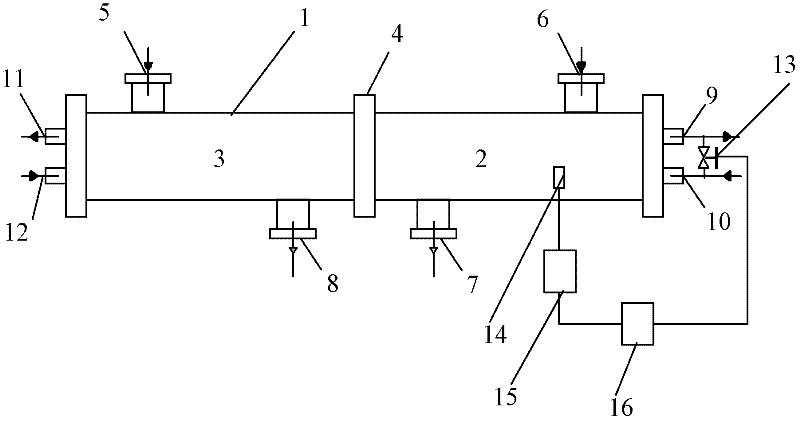

[0015] The double channel condenser with heat recovery and condensation temperature control structure of the present invention integrates the function of heat recovery device and the condensation function of ordinary condenser, and it is provided with three groups of inlets and outlets: refrigerant inlet and outlet, cooling water inlet and outlet and hot water circulation Import and export, see the specific structure figure 1 , the structure of this condenser is:

[0016] A tubular heat exchanger 1, with a metal baffle 4 in the middle, divides the tube body of the heat exchanger 1 into two parts, the first cavity 2 and the second cavity 3, and the metal baffle 4 is placed in the tube body Some have several through holes;

[0017] The first cavity 2 and the second cavity 3 are respectively provided with refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com