Rotary cylinder piston type engine

A technology of engine and rotary cylinder, which is applied in the field of high-power engines, can solve the problems of difficult sealing, difficult sealing of the expansion cavity, and less than 10,000 revolutions, and achieve the effect of reducing the overall machine components, reducing the volume, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] 1. Various parts of the engine

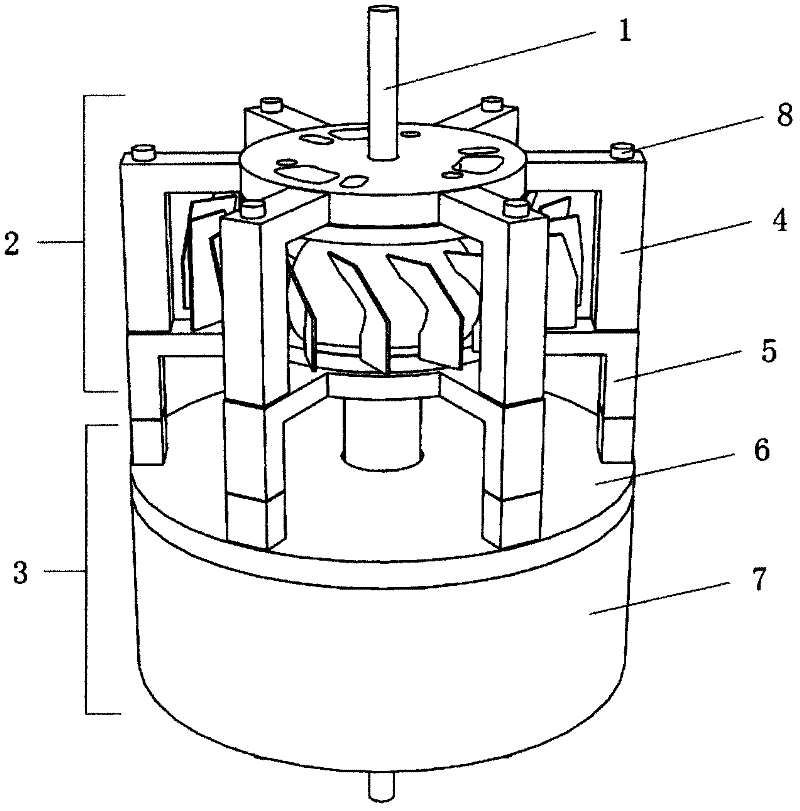

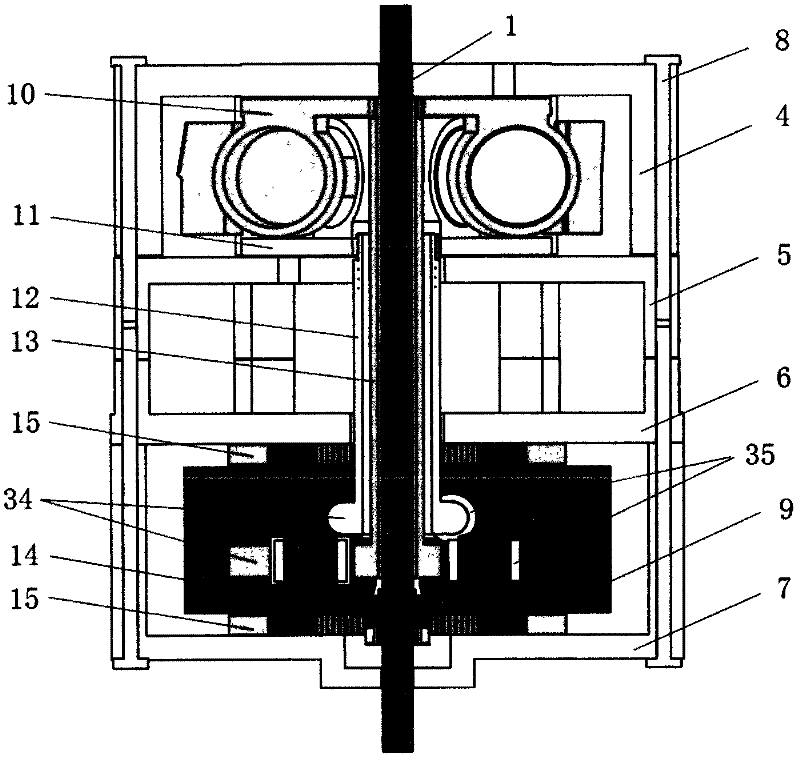

[0039] Such as figure 1 As shown, it is a schematic diagram of the appearance of the whole machine. From the figure, it can be clearly understood that the upper part of the engine is the combustion system assembly (2) of the engine, the lower part is the engine drive train assembly (3), and the output shaft (1) is located at At the central axis, the two ends are exposed from the upper and lower end faces, which can be connected to generators, starter motors and other components. The whole machine is composed of 4 shell components, the upper bracket (4) and the lower bracket (5) realize the fixing of the upper rotor component (10) and the lower rotor component (11), and also realize the ventilation of the two rotor components . The transmission cavity upper cover (6) and the transmission cavity body (7) are combined to seal the transmission cavity of the complete machine, and the transmission components of the engine are installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com