Point pillar type full-ore-deposit middle-section-free upward high-layering continuous propelling fill mining method

A filling mining and point column technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of reducing the amount of development and mining standards, shortening the connection time of mining and filling, and high costs, so as to achieve the reduction of development and mining standards. The effect of reducing the amount of work, shortening the connection time of mining and charging, and reducing the amount of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A low-grade iron ore deposit of sedimentary-metamorphic rock type belongs to inclined-steeply inclined ore bodies. The thickness of ore bodies and interlayers varies greatly. The main ore body in the mining area controls a strike length of 1365m, and the maximum thickness of the mine hole is about 100m. It is designed to mine 1.2 million tons of raw ore per year, and the ore body within -120m to -320m is mined in the first phase. The ground surface is not allowed to collapse, and the filling method is used for mining.

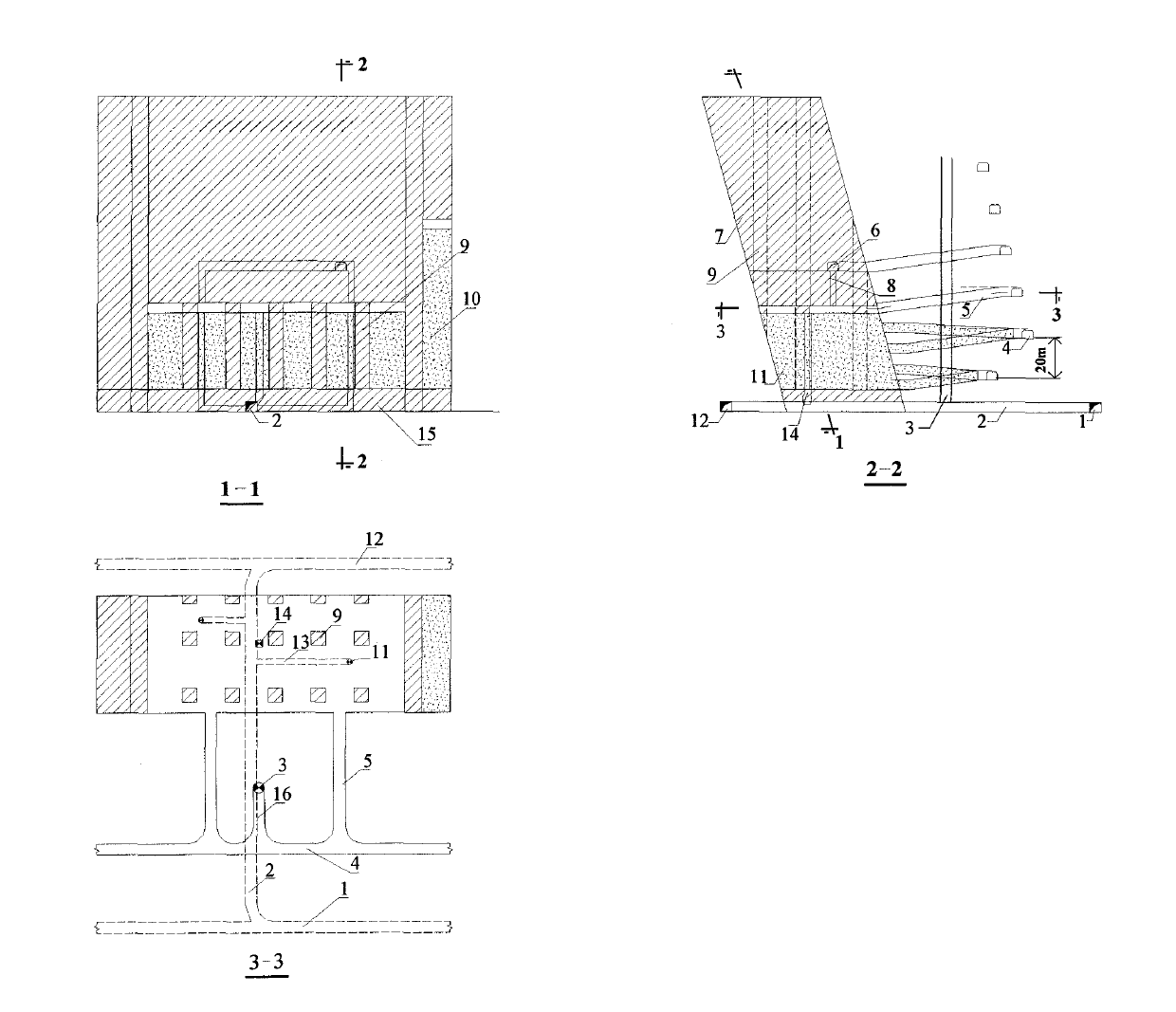

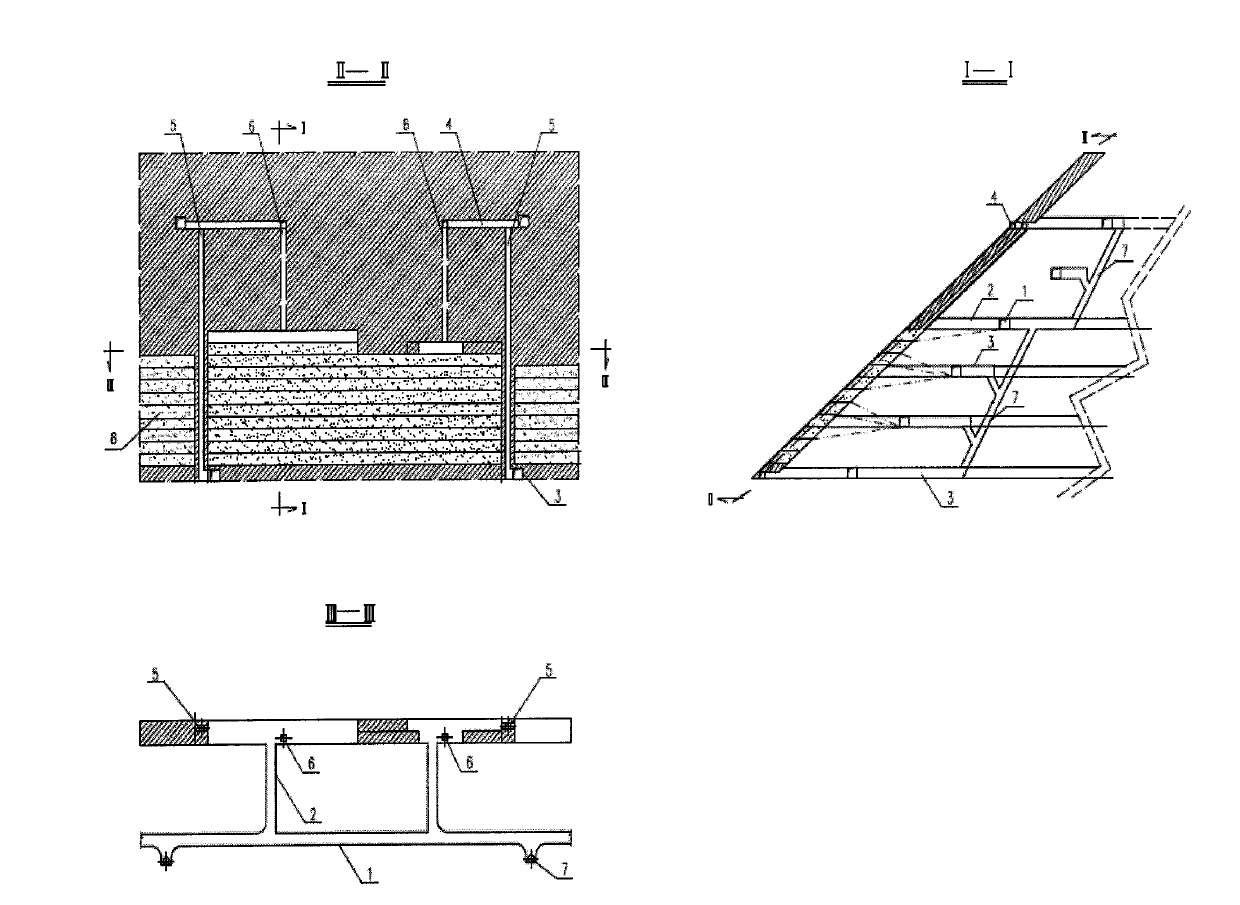

[0023] The original mining design scheme was the mining method of subsection emptying and then filling. Due to the large amount of mining work in the early stage, it was later decided to adopt the point-pillar method of continuous advancement of filling mining regardless of the middle section and upward to the high layer. The method is detailed in the appendix. image 3 , the specific scheme is as follows.

[0024] 1. Stope arrangement: The panels are a...

Embodiment 2

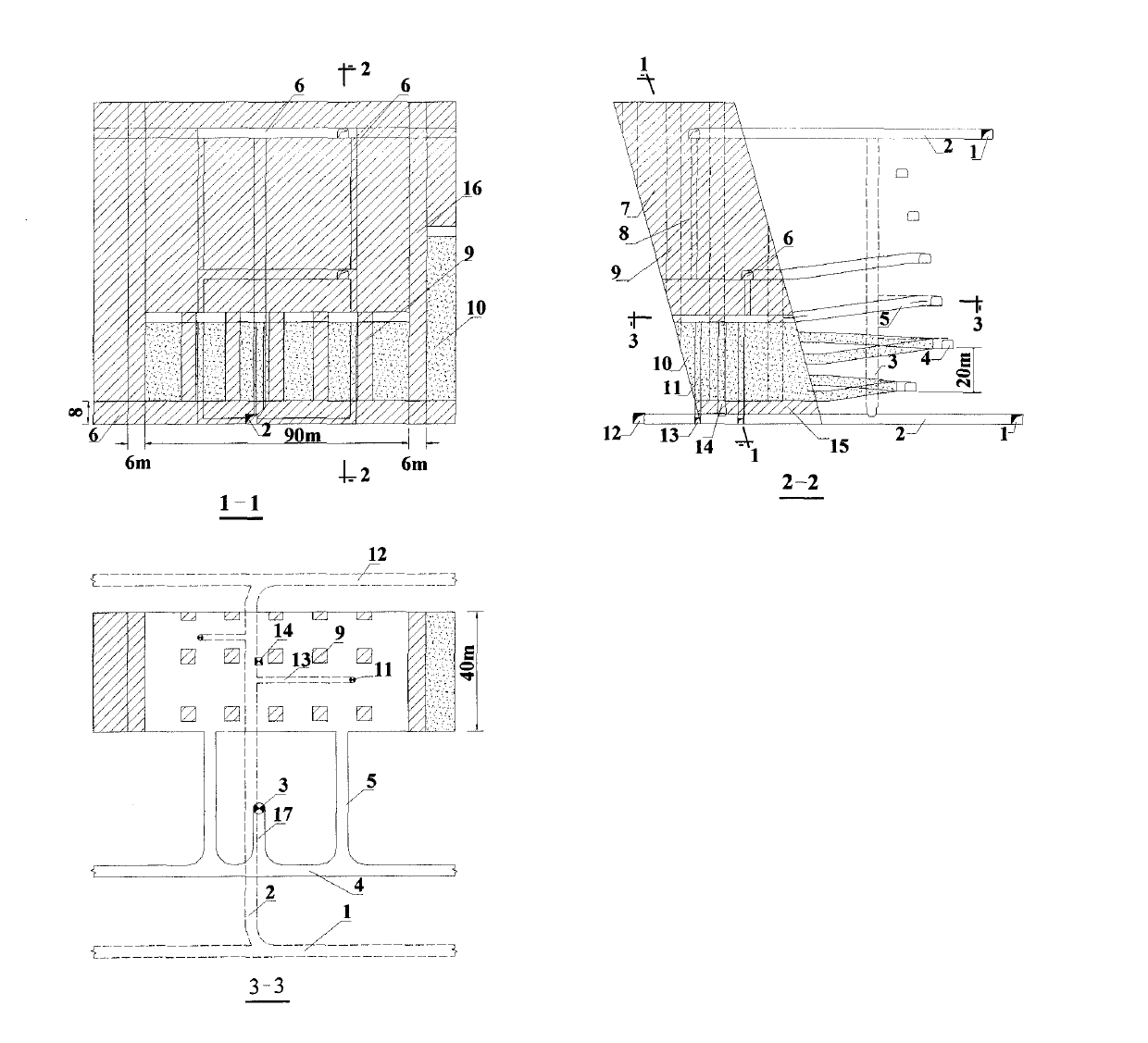

[0033] The ore body of an underground iron mine is saddle-shaped and belongs to the gently inclined to inclined ore body. The main ore body has two upper and lower layers. The thickness of the rock between the two ore bodies is about 15m, and the thickness generally ranges from 4 to 25m. The strike length is nearly 2.5km . The average geological grade of the mining area is 31.4%, and the magnetic iron content is 16-18%. The ore body above -140m is mined in the first phase, and the slope and vertical shaft are jointly developed. 2 million tons.

[0034] The total pressure-bearing area of the iron ore is large, and the span of the inclined surface is large, which restricts the adjustment and selection of the stope structural parameters; the ore body is scattered, and the amount of mining work at each segment level is large, so it is difficult to form a large-scale mining deposit. After research, it is decided to adopt the technical scheme of the present invention below -40m, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com