Multi-body discontinuous coal petrography cutting equipment

A non-continuous, coal cutting technology, applied in cutting machines, earthmoving machines/shovels, earth-moving drilling, etc. The effect of improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The examples of the present invention will be further described below in conjunction with the accompanying drawings:

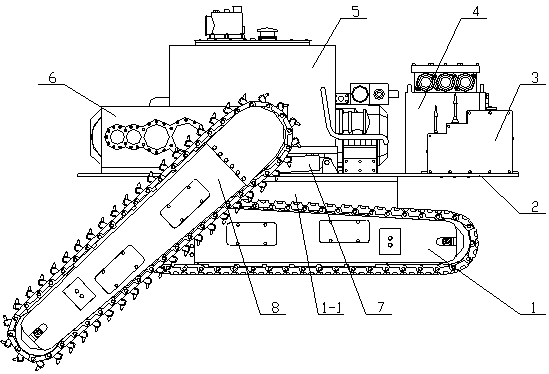

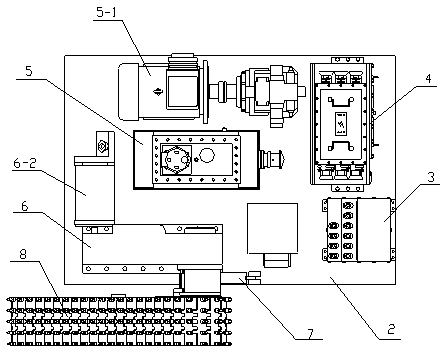

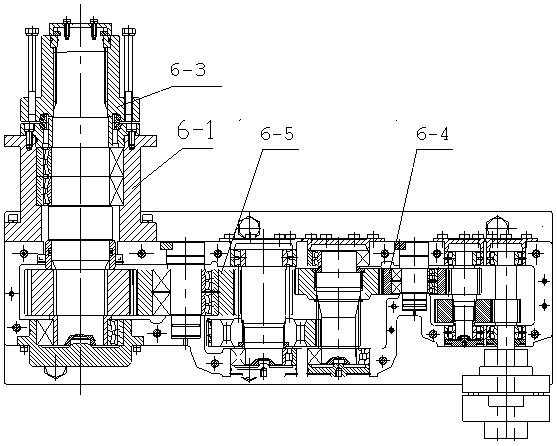

[0013] As shown in Figure 1 and Figure 2, the multi-body discontinuous coal and rock equipment of the present invention is mainly driven by crawler walking device 1, support platform 2, driver console 3, electric control box 4, pump station 5, reducer 6, and hydraulic drive Device 7, multi-body discontinuous cutting coal and rock device 8; crawler walking device 1 is set on support platform 2, driver console 3, electric control box 4, pump station 5, reducer 6 and hydraulic pushing device 7 are fixed in sequence On the support platform 2, the root of the output shaft of the reducer 6 is provided with a fixed sleeve 6-1, and the head is connected with a multi-body non-continuous coal and rock cutting device 8 provided on one side of the support platform 2. The coal and rock device 8 is arranged obliquely. The crawler walking device 1 is composed of a crawle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com