Automatic feed supplement mechanism for LED braiding machine

A braiding machine and automatic technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve the problems of high man-machine ratio, no patent document of tape braiding machine image feeding mechanism, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

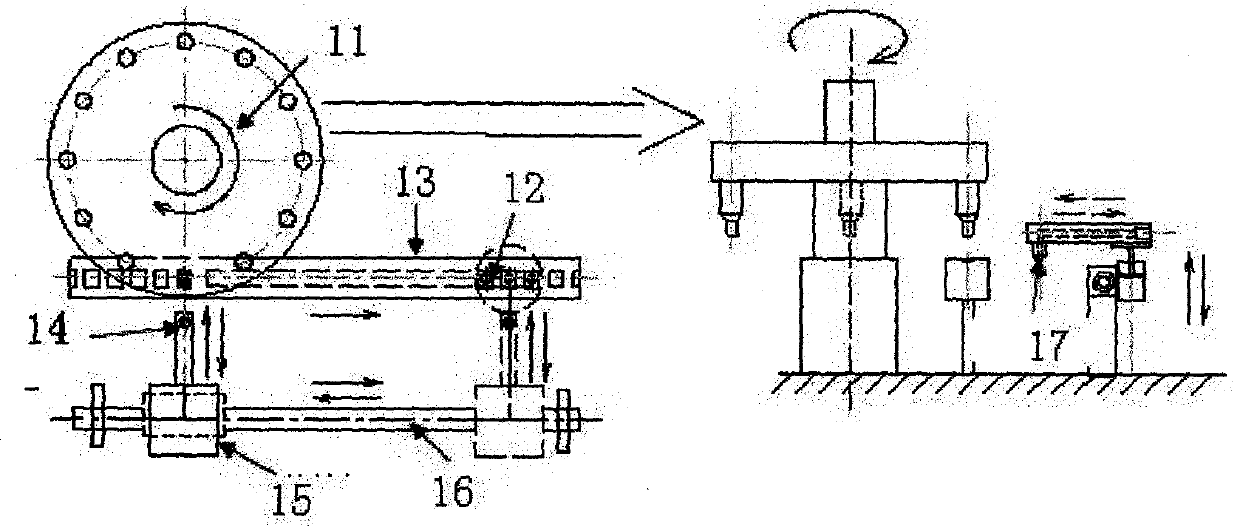

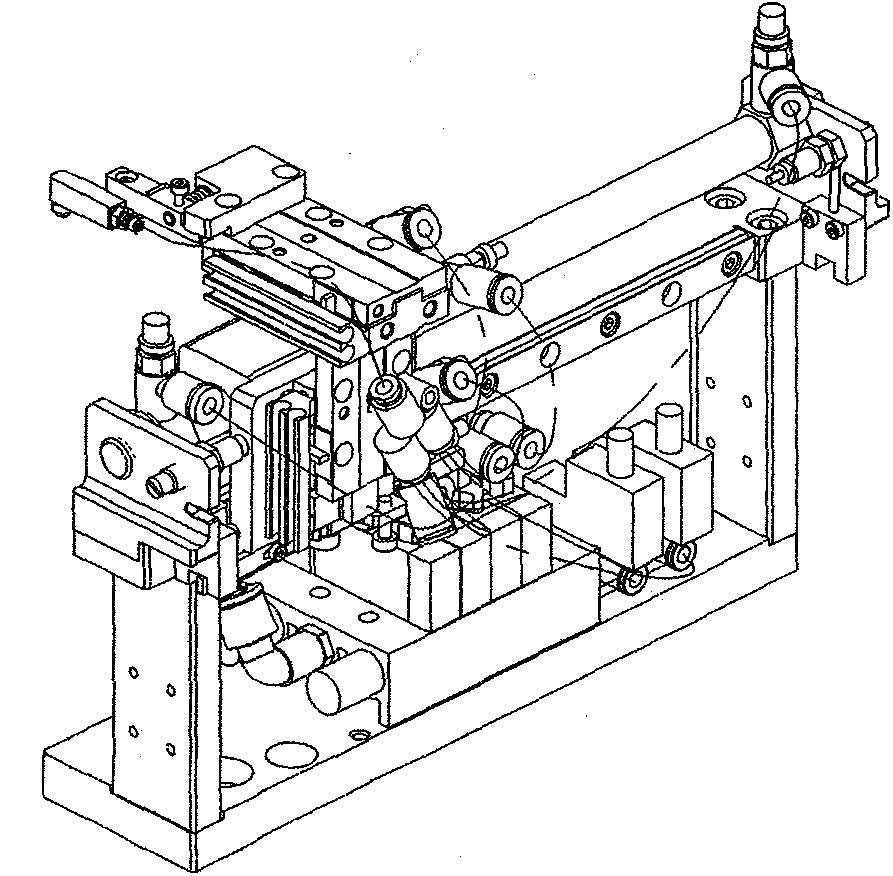

[0025] Such as figure 1 and figure 2 As shown, under normal circumstances, this part is designed to solve the discharge of defective products at the image test end and take a piece of material from the entrance of the carrier tape to replace it at this position. During the taping process, the image detection CCD detects 1 station in real time, that is, 12 materials at the image position. If any abnormalities such as reverse material, side material or broken material are found, the automatic feeding manipulator will return the "bad" material from the carrier tape. Take it out and discharge it into the accumulator, then take a piece of material from the entrance 14 of the carrier belt (2 stations) and put it back to the position of 1 station, and the manipulator returns to its position. At this time, the impact detection CCD will compare the image again, if pass, the machine will continue to weave the tape along the tape guide rail 13, otherwise repeat the above feeding proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com