Micromechanical controllable flapping rotary wing aircraft and manufacturing method as well as control method thereof

A technology for micro-machines and aircraft, applied in the field of aircraft, can solve the problems of inability to achieve steering and forward flight, and achieve the effects of low cost and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

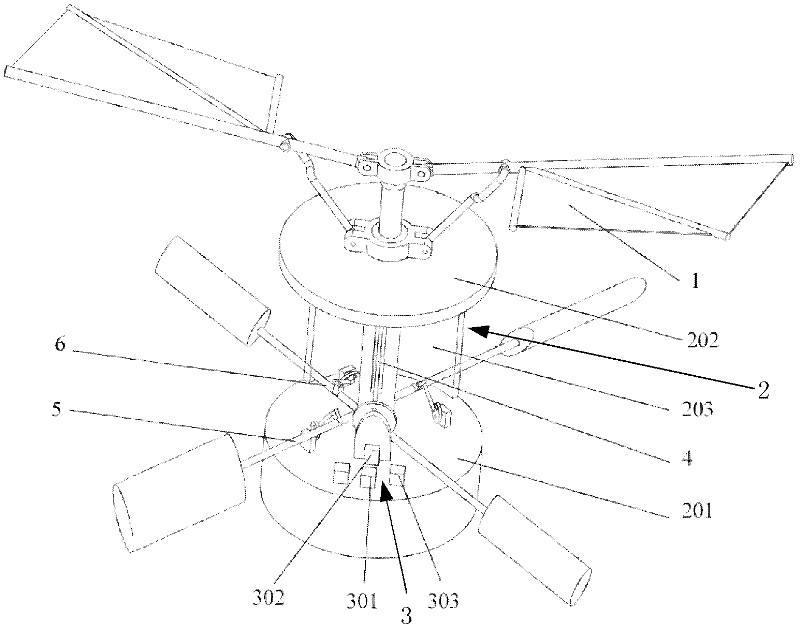

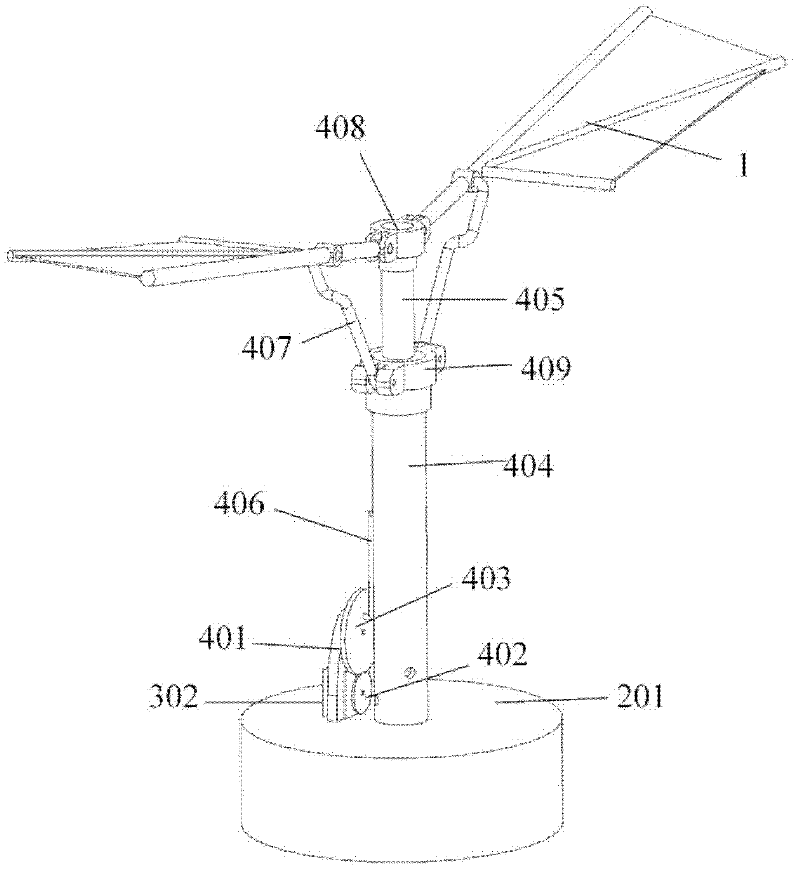

[0051] The present invention is a micro-mechanical controllable flapping rotor aircraft, such as figure 1 As shown, it includes a wing 1, a fuselage 2, a power plant 3, a transmission mechanism 4, a steering control system 5 and a forward flight control system 6.

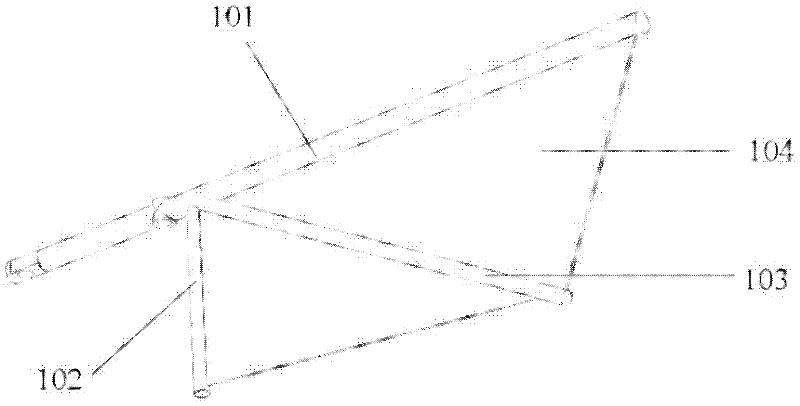

[0052] The wing 1 is as figure 2 As shown, the wing 1 is two identical membrane wings, and each wing 1 is composed of a main beam 101 , two auxiliary beams (short auxiliary beam 102 , long auxiliary beam 103 ) and a membrane 104 . The main beam 101, the short auxiliary beam 102 and the long auxiliary beam 103 are made of carbon fiber rods, and the wing film 104 is made of polyethylene film. The main beam 101 is coplanar with the short auxiliary beam 102 and the long auxiliary beam 103, the short auxiliary beam 102 is perpendicular to the main beam 101, the long auxiliary beam 103 is betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com