Mechanical electric lifting mechanism for dump truck

A lifting mechanism and mechanical technology, applied in the direction of tilting and carrying vehicles, can solve the problems of high maintenance cost, good static performance, and short service life, so as to overcome the oil leakage of hydraulic dump trucks and improve the working environment , Easy maintenance and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

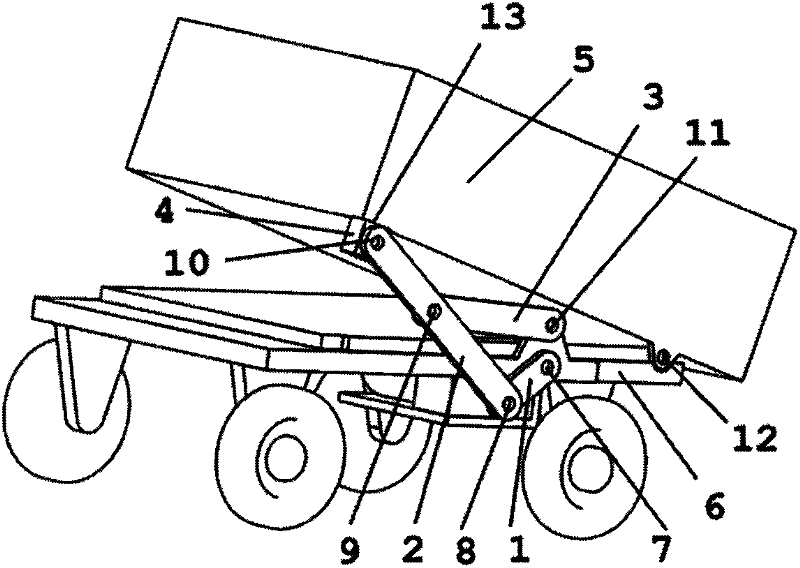

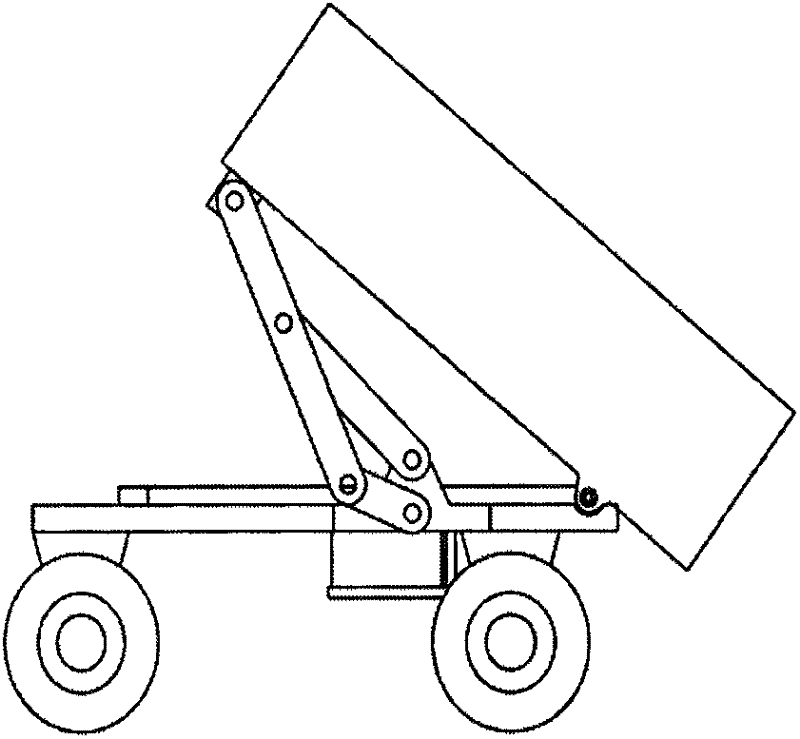

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples.

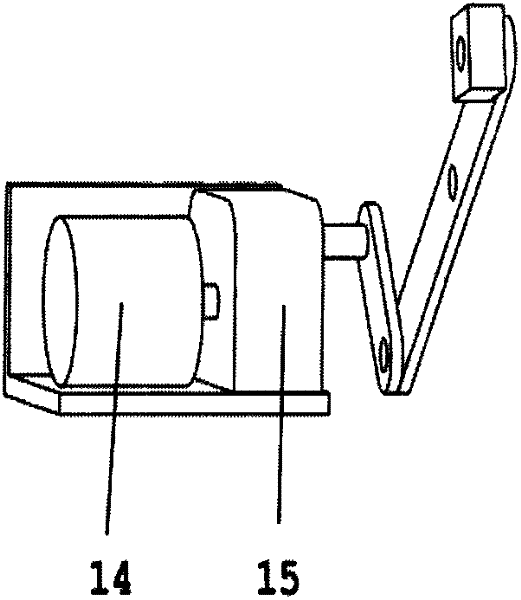

[0015] control figure 1 , 2 , the electric lifting mechanism for dump trucks includes a driving rod 1 , a connecting rod 2 , a driven rod 3 , a slider 4 , a bucket 5 , a vehicle frame 6 , a reducer 15 and a motor 14 . One end of the active rod 1 is connected to the vehicle frame 6 through the first rotating pair 7, the other end is connected to the connecting rod 2 through the second rotating pair 8, and the other end of the connecting rod 2 is connected to the slider 4 through the fifth rotating pair 10, so The middle of the connecting rod 2 is connected with the driven rod 3 through the fourth rotating pair 9, the other end of the driven rod 3 is connected with the vehicle frame 6 through the third rotating pair 11, the slider 4 is connected with the bucket 5 through the moving pair 13, and the vehicle The rear end of the buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com