Poultry segmental coma-inducing slaughtering method and equipment using same

A poultry and equipment technology, applied in poultry/fish slaughtering/stunning, electric current slaughtering/stunning, etc., can solve problems such as conflicts between human animal welfare and product quality, danger to operators, and impact on product quality, and achieve effective Facilitate transportation and maintenance, reduce floor space, and facilitate process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

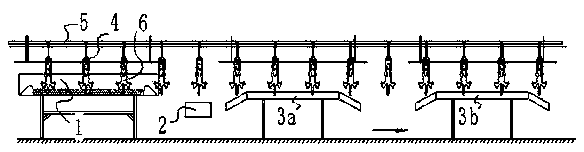

[0029] attached by figure 1 Shown: This poultry multi-stage stunning slaughtering equipment includes:

[0030] A water bath electric stunner 1;

[0031] a poultry killing station 2;

[0032] A plurality of flat-panel electric stunners 3a, 3b;

[0033] The track 5 with the poultry hook 4 on it is arranged on the water-bath electric stunner 1, the poultry slaughter station 2 and a plurality of flat electric stunners 3a, 3b;

[0034] The poultry slaughter station 2 is set between the water-bath electric stunner 1 and the first plate-type electric stunner 3a, and the set voltage of the water-bath electric stunner 1 does not exceed 36 volts. The set voltage of each flat-type electric stunner 3a and 3b does not exceed 24 volts, and the number of flat-type electric stunners set is set according to the poultry species.

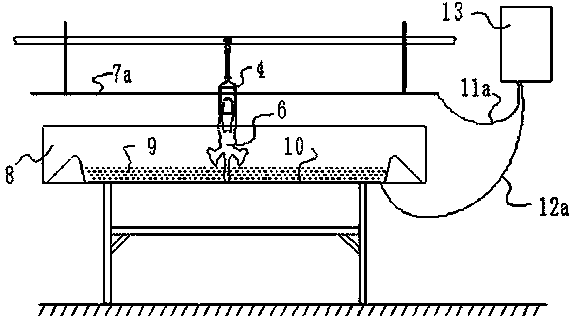

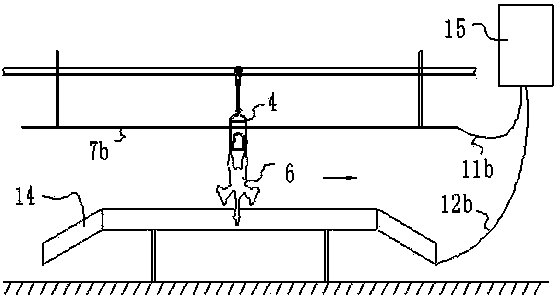

[0035] attached by figure 2 As shown: the water-bath electric stunner includes a track 5 with a plurality of poultry hooks 4 suspended, a negative electrode 7a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com