Brush hole type plug seedling planter

A technology of plug seedling raising and seeding machine, which is applied in the field of seeding machines, can solve the problems of reducing operating efficiency, difficulty in cleaning holes, and time-consuming, etc., and achieves the advantages of reducing labor intensity, improving hole insertion rate and reliability, and strong interchangeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

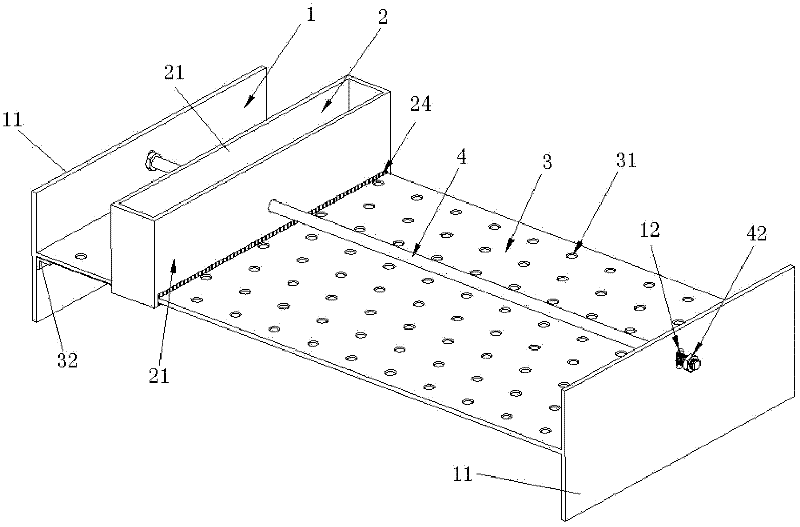

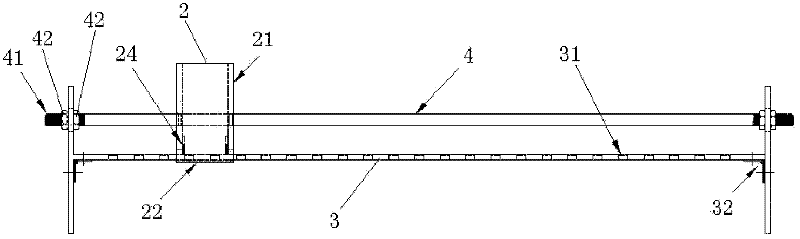

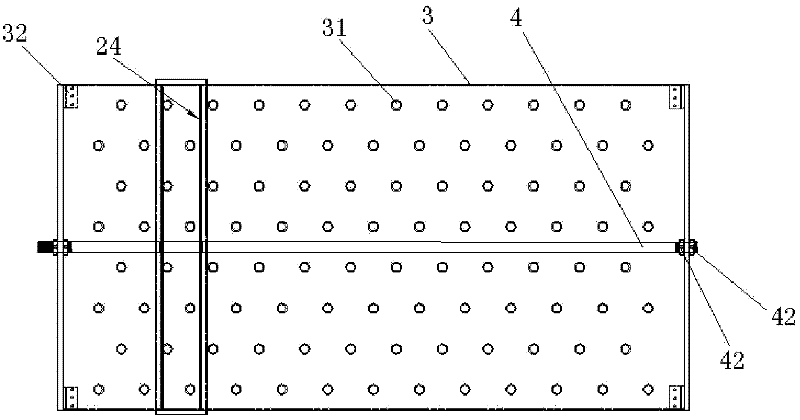

[0018] Such as Figure 1~3 As shown, the present invention includes a support 1, a seed box 2, a seed board 3 and a guide slide bar 4.

[0019] Such as Figure 1~3 As shown, the bracket 1 of the present invention includes two rectangular support plates 11 arranged parallel to each other and perpendicular to the working surface, and each of the two support plates 11 is provided with an adjustment hole 12 .

[0020] Such as Figure 4 As shown, the seed box 2 of the present invention is in the shape of a cuboid, the lower part of the side walls 21 in the length direction of the seed box 2, and the same position above the bottom plate 22 of the seed box are respectively provided with a strip-shaped through hole 23, two strip-shaped The inner wall of the seed box 2 above the through hole 23 is respectively provided with a strip brush 24 .

[0021] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com